1. What is a heat exchanger?

A heat exchanger is a device used to transfer heat from one medium to another. It is commonly used for heating or cooling purposes. Common types include plate heat exchangers, shell-and-tube heat exchangers, and finned-tube heat exchangers.

2. What type of heat exchanger do we need?

This depends on your application requirements, such as:

Our engineering team can provide professional advice based on your specific needs.

3. How do I choose the right heat exchanger model?

Selecting a heat exchanger requires consideration of the following parameters:

You can provide detailed application data, and our technical team will recommend the appropriate model for you.

THT Relevant Products

| ITEM | NAME |

| 1 | COPPER BASE BRAZING JC50 |

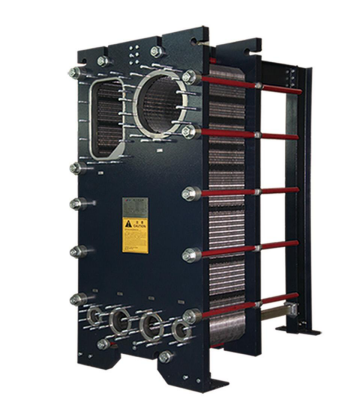

| 2 | T15 Plate Heat Exchanger |

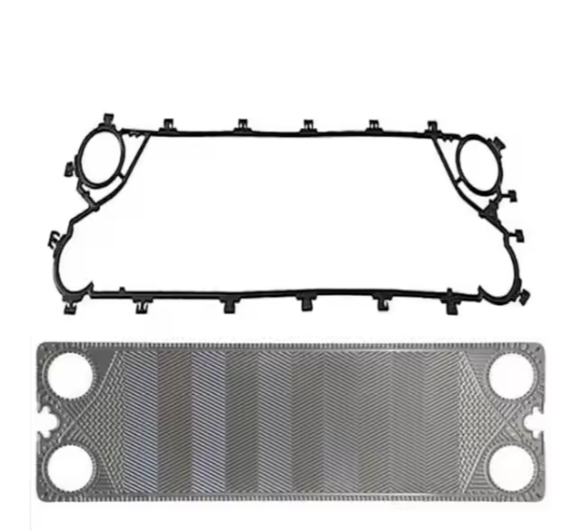

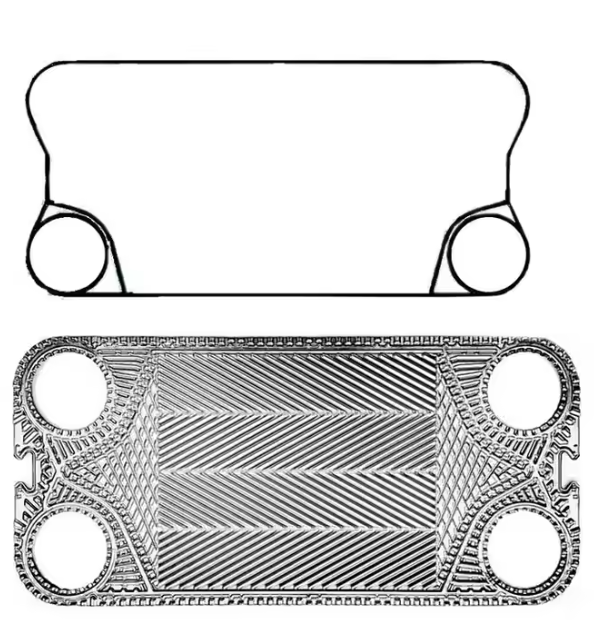

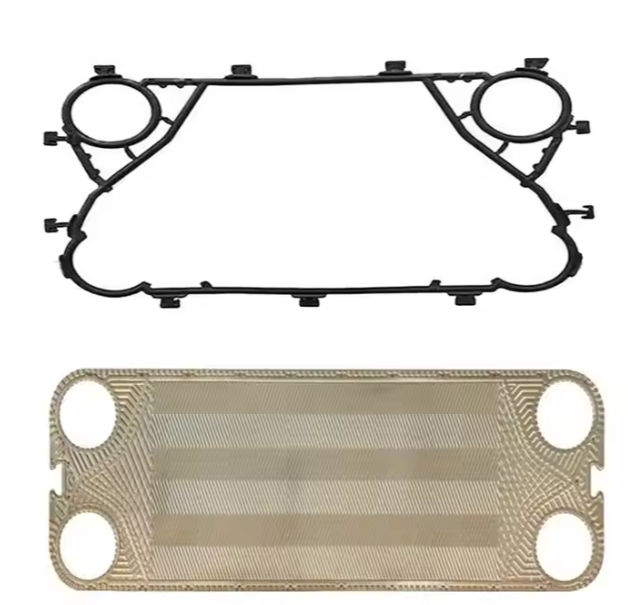

| 3 | Plate Heat Exchanger Gasket |

| 4 | Top Quality 304 316 Stain Stainless Steel Plate |

| 5 | COPPER BASE BRAZING LC200 |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

plate heat exchanger,

integrated heat exchange unit,

heat exchanger,

heat exchange unit ,

box heat exchange station,

integrated heat exchange system