Instead of servo electric cylinders, it’s powered by digitally controlled high-speed servo motors, allowing for a faster, repeatable, more precise, and energy-efficient operation. As we all know, Electric machine operation should be highly predictable. Once a desirable injection process has been reached, it can be pasted very consistently, resulting in higher quality parts. Once an indication has been programmed into an electric machine, its digital controls allow it to run virtually unattended, which help us lower labor costs and boosts profits.

Thanks to it posing no risk of oil contamination, electric injection molding is well-suited for cleanroom applications. Because of its high precision, this process is also ideal for small- to medium-sized parts and medical products such as Petri dishes and syringes.

-Cleaner operation that never leaks fluid

-Less downtime commonly associated with hydraulics

-Good for Energy savings from 30% to 70%

-Lower noise; reduced motor noise below 70 dB

-Higher rapid injection speeds up to 1000 mm/sec and faster clamp motion

-Tight precision and repeatability with reduced scrap rates

-Shorter startup time and up to 20% faster cycle times

-Lower unit cost and less material waste

-Requires no consumables such as oil that would need to be replaced or cleaned

-Lower power requirements result in significantly lower operating cost

ST85 Specification

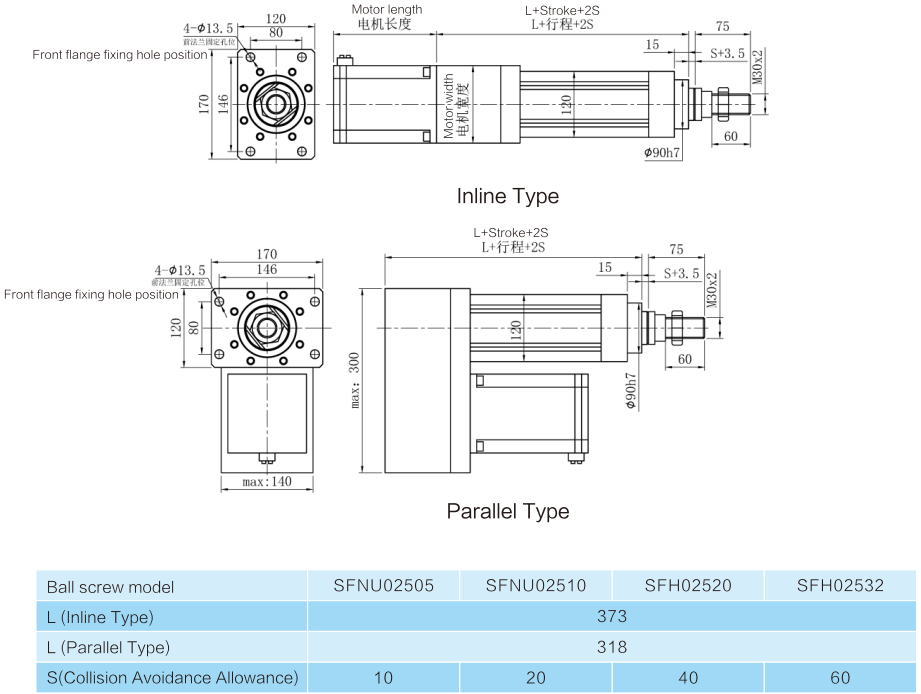

Note:

1.If you need drawings and life of ball screw, please consult customer service for details.

2.If the maximum stroke exceeds 500mm,it is recommended to add a guide device.

3.The Parameters may be affected by different brands of motors,please consult customer service for details.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

electric actuator,

hydraulic cylinder,

coil strapping machine ,

Steel coil production and packaging unit,

Fully automatic steel pipe stacking production and,

equipment and system solutions for steel coil logi