Introduction

Medicinal packing is not merely containment; rather, it relates to safety, sterility, and functionality. Translucent PVC has become indispensable within the industry in applications like urine bags and IV bags that call for clear visibility, durability, and biocompatibility. The paper will analyze in detail the features of translucent PVC film, the position and purpose of the material in medical packaging with particular emphasis on urine bags, and incorporation in composite films for enhancement of functionality. Characteristics of Translucent PVC Film

Translucency:

Unlike fully transparent materials, translucent PVC assumes a frosted appearance that diffuses light to provide privacy yet allows for the needed visual inspection of contents. This is important in medical applications whereby patient confidentiality would be required and yet monitoring of fluid levels or medication is done.

Flexibility and Resilience:

PVC films boast of flexibility, which is an important aspect in medical bags that need to conform to the body or be manipulated during use. Besides the flexibility, PVC retains high tensile strength; it is resistant to punctures, tears, and impacts-features important for the integrity of medical devices through different environments.

Biocompatibility:

The formulation of PVC employed in medical use is made biocompatible by minimizing adverse reaction incidents with either bodily fluids or tissues. That compatibility extends right to the stability of the film when in contact with various medications or treatments with which it would come into contact, so as not to let the packaging degrade or interact with its contents adversely.

Heat Sealability:

Since there is a need for medical packaging to hermetically seal products from contamination and ensure sterility, the ability of PVC to form tight seals when heat is applied is important. This property is especially helpful for urine bags, where leaks could lead to infections or other serious health risks.

Chemical Resistance:

It resists many of the chemicals, acids, and bases that are common in medical settings, which means that medical packaging can be far more durable and safe. This becomes important if urine bags need to endure different disinfectants or cleaning agents. Sterilizability:

One of the other favorable attributes is that PVC can support multiple methods of sterilization, from autoclaving to gamma radiation to ethylene oxide gas, without any significant degradation of its material properties.

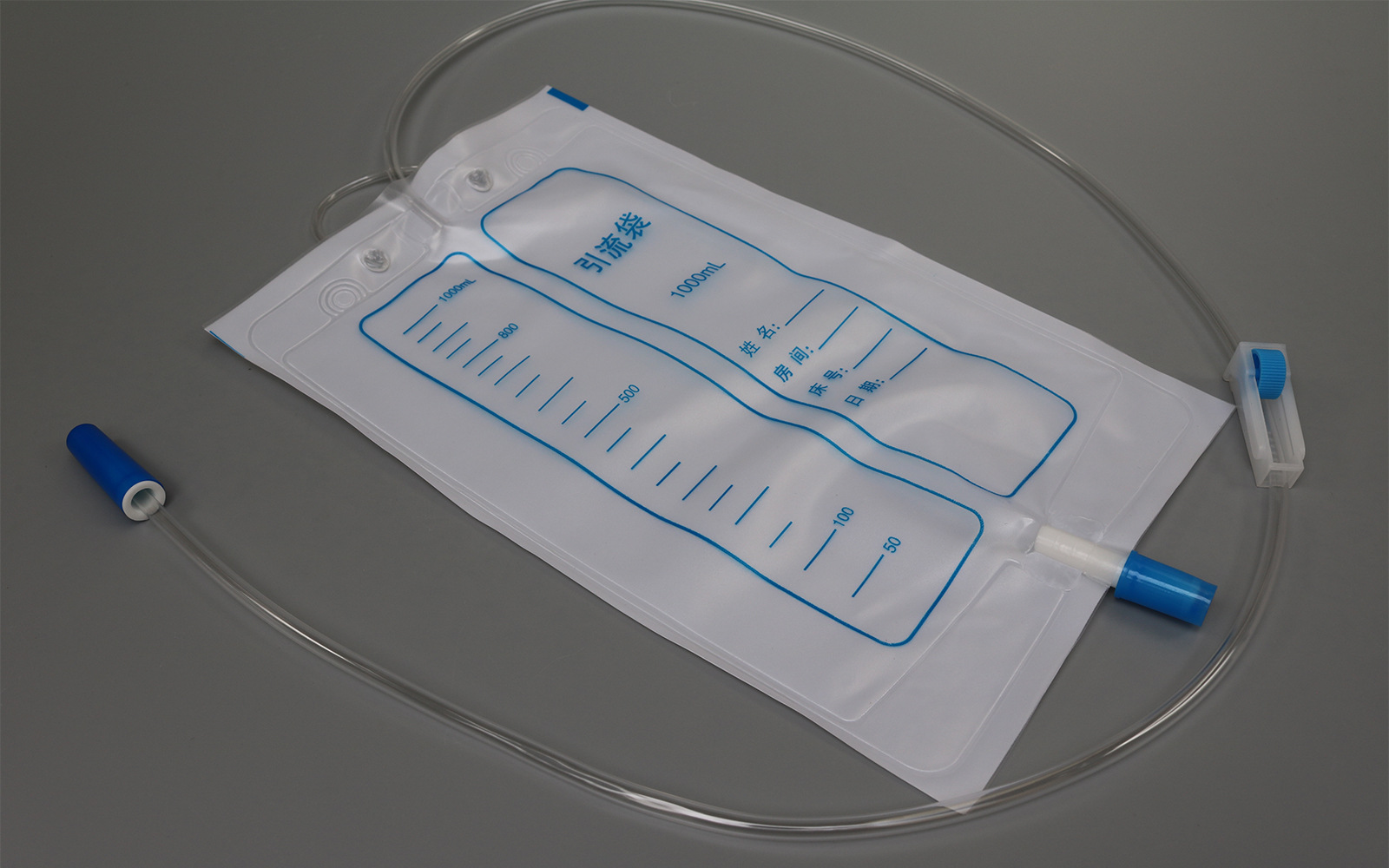

Applications in Medical Packaging, Particularly Urine Bags

Urinary Bag Systems:

Transparency: The semi-transparent nature of PVC enables nurses and doctors to easily observe the urine output without any loss of modesty for the patient, which is critical for the maintenance of patient fluid input and renal function.

Strength: The resistance of PVC is such that urine bags can bear the tugging, hanging, and weight of fluids collected inside without any failure, whether in a hospital environment or at home.

Sterilization: The heat-sealing of the PVC provides a hermetic seal that is designed to reduce infection risk. This is a major concern in urinary catheters and their bags.

Other Medical Applications:

IV Bags: Much like the urine bags, IV bags use PVC for the clarity in fluid level observation, the flexibility for patient comfort, and the durability for safe transport.

Blood Bags: Blood storage is the area where, due to the properties of the material, sterility and non-leakage are very important.

The Role of Laminated Films

Enhancing Properties Through Lamination:

Barrier Enhancement: The barrier properties can be substantially improved by laminating PVC with other films such as polyethylene or polyamide, thus offering better protection against oxygen, moisture, or microbial ingress.

Durability: Adding layers by lamination can give additional puncture resistance or a more robust exterior without taking anything away from the inner PVC's translucency and flexibility.

Specialized Functions: Some laminate layers may include UV blockers for light-sensitive medications or coatings that would allow writing or labeling directly on the bag for enhanced traceability and record-keeping.

Compatibility: Lamination can be made compatible with various sterilization methods or enhance the heat-sealing capability for more complicated packaging designs.

Innovations in Medical Packaging:

Peelable and Resealable Features: Modern PVC films can incorporate peelable seals for easy access or resealable features for multi-use applications, like collecting samples over time.

Sustainability: Although PVC has environmental issues, the advancement in recycling and biodegradable additives is turning PVC films more 'green', hence fitting into the move towards sustainability within the healthcare industry.

Conclusion

Medical applications, particularly in packaging, are dominated by translucent PVC film because of the combination of transparency, strength, and biocompatibility it provides, especially in applications like urine bags. Lamination with other materials further extends the utility by offering improved protection and functionality. The development in PVC films will be dictated by the need for safer, more effective,

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film ,

PC Film,

PP Film,

Other plastic packaging products