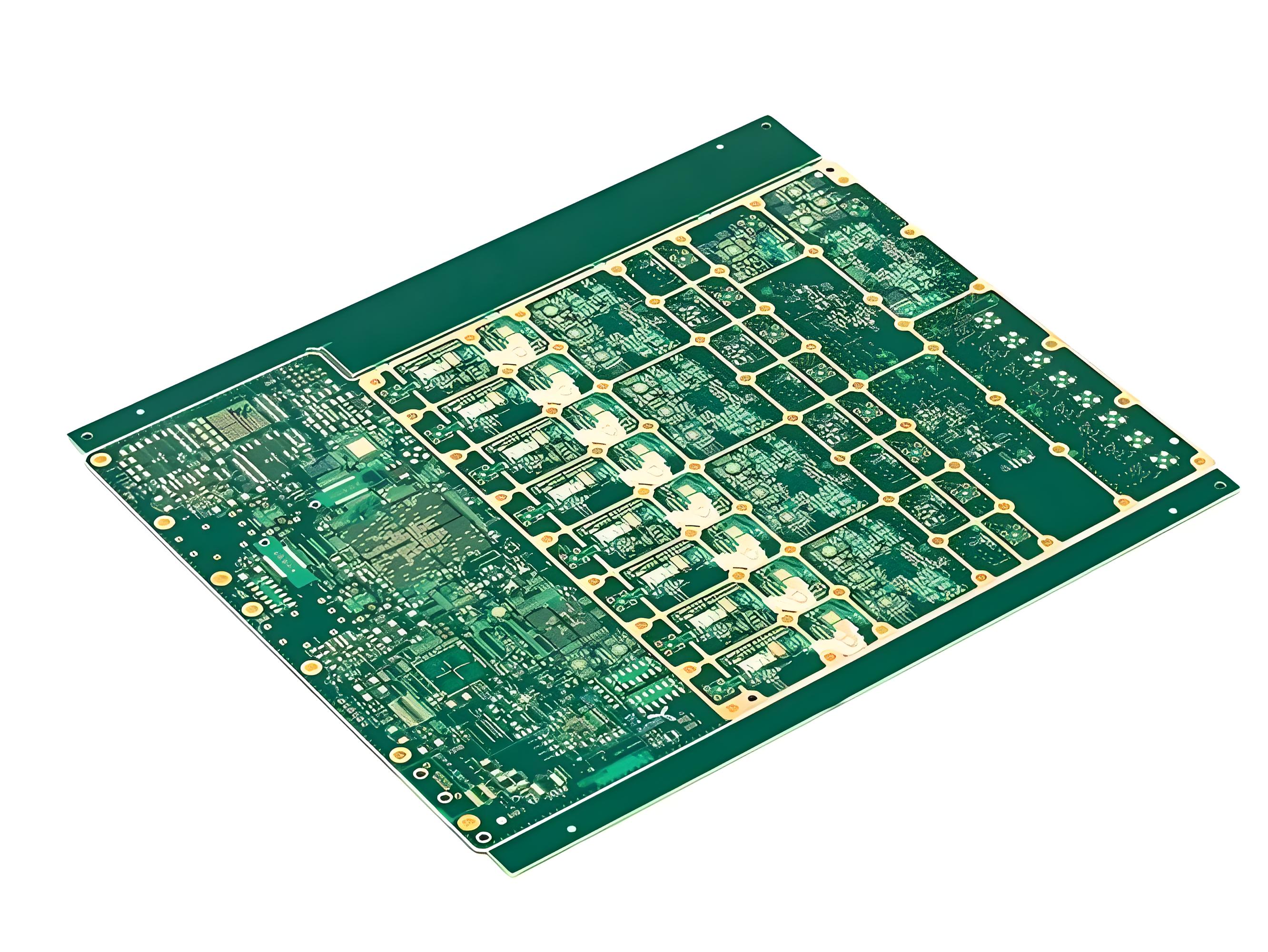

Carbon ink PCB (printed circuit board) is a PCB where carbon-based conductive ink (referred to as carbon ink) is coated on the PCB substrate and cured to form a PCB with a carbon film conductive pattern. As the market demands for reducing PCB production costs continue to rise, replacing expensive golden keys with carbon oil keys has become a general trend. Carbon oil board is a commonly used surface treatment method for single and double PCBs, ensuring reliable long-term operation through processes like inspection, testing, and burn-in testing.

Carbon ink exhibits strong adhesion, peeling resistance, and wear resistance, withstanding up to ≥1 million cycles and a resistance change rate ≤10%. Compared to other metals, the square resistance of conductive paste is relatively large, but the carbon oil plate’s square resistance can generally be controlled at ≤ 20 ohms, offering high cost-performance. Conductive pastes are crucial for electronic component packaging, electrodes, and interconnection, primarily comprising aging conductive paste and curing conductive adhesive (conductive ink).

Carbon oil sheets are utilized in thin film circuits, mobile phone soft circuits, medical equipment, communication devices, automotive electronics, smart label RFID, and numerous other industries. In the circuit board industry, they are predominantly used in calculators and remote controls, replacing processes like copper plated hole, silver paste hole filling, and copper paste hole filling. Environmentally friendly and low-cost carbon paste hole filling represents the mainstream trend in circuit board development. Notably, Microsoft uses carbon oil to fill holes on power boards, fully replacing double-layer boards with copper-plated holes.

Due to carbon oil’s excellent electrical conductivity, a gap is necessary on the finished board to prevent short circuits. Typically, the minimum clearance for the finished product should be 8mil (HOZ bottom copper) and 12mil (1-3oz bottom copper), increasing if the film is opened.

The minimum alignment tolerance for carbon oil is +/-6mil.

Considering alignment tolerance and oil leakage, to ensure no copper exposure, the carbon oil must be 6mil (HOZ bottom copper) or 8mil (1-3OZ bottom copper) greater than copper pads on one side. A gap of 6 mil (HOZ bottom copper) and 8 mil (1-3OZ bottom copper) is required between the carbon oil window and surrounding copper pattern to prevent the carbon oil from covering it and causing short circuits.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

printed circuit board,

pcb assembly,

pcb design,

plasma nano protection,

electronic components ,

pcb protoyping