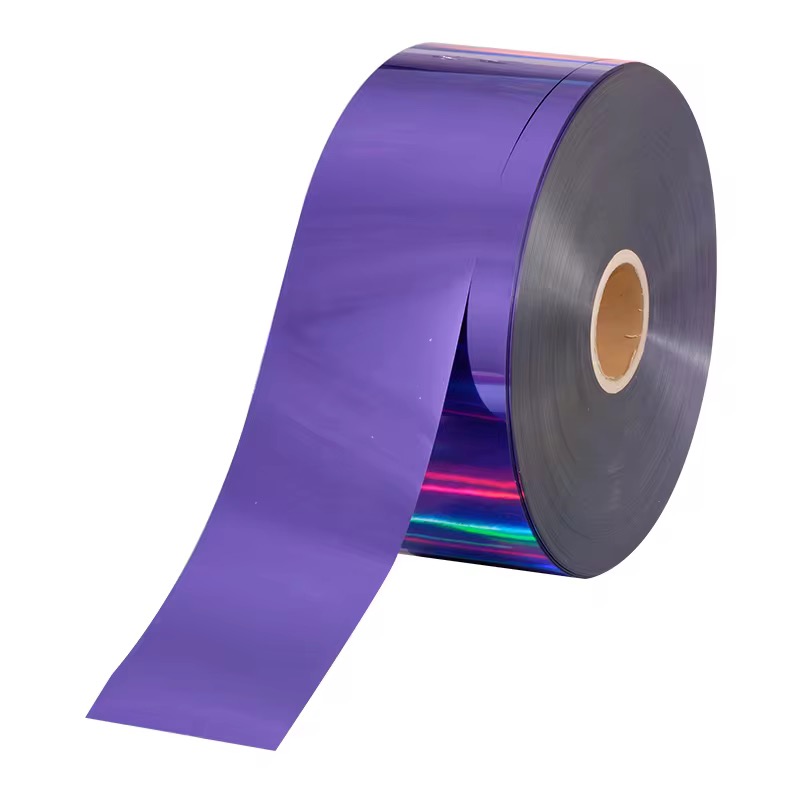

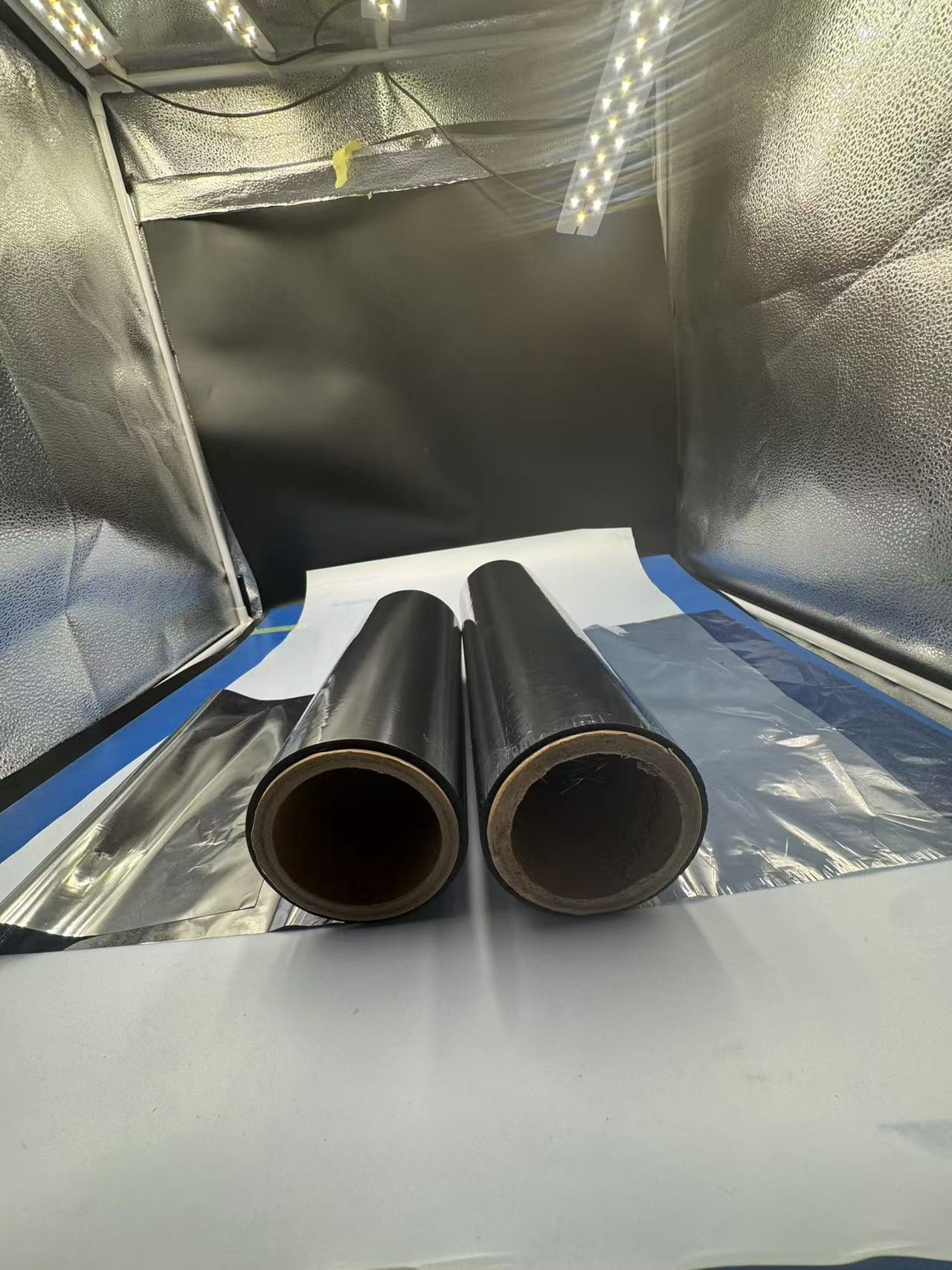

In the ever-evolving world of packaging, one material stands out for its exceptional blend of functionality, aesthetics, and versatility: PET metallized film.

This innovative material, created by coating a thin layer of metal—typically aluminum—onto a polyethylene terephthalate (PET) substrate, has transformed industries ranging from food to pharmaceuticals. Its unique properties make it a go-to solution for modern packaging needs, offering a compelling alternative to traditional materials like aluminum foil. In this article, we’ll explore the characteristics of PET metallized film and dive into its diverse applications across various packaging sectors, showcasing why it’s a game-changer in the field.

The Core Characteristics of PET Metallized Film

PET metallized film is a marvel of materials science, combining the inherent strengths of PET with the enhanced properties imparted by a metallic coating. Let’s break down its key characteristics:

These properties collectively make PET metallized film a versatile powerhouse, bridging the gap between functionality and aesthetics in packaging solutions.

Applications of PET Metallized Film in Packaging

The adaptability of PET metallized film shines through in its wide-ranging applications across industries. Here’s how it’s making an impact:

Consider a real-world scenario: a bag of freeze-dried fruit sealed in PET metallized film. The film prevents moisture ingress, maintaining the fruit’s crispness, while its reflective surface shields it from sunlight, preserving vitamins and color. This dual protection extends shelf life without compromising quality, delighting both producers and consumers.

Picture a blister pack of light-sensitive pills: the metallic layer reflects harmful rays, keeping the active ingredients potent. This reliability makes PET metallized film a trusted choice for pharmaceutical companies worldwide.

Imagine a high-end moisturizer tube: the PET metallized film exterior gleams under store lights, signaling quality, while the interior coating keeps the cream fresh. This combination of style and substance makes it a staple in the beauty industry.

A vivid example is its role in flexible packaging for electronics: a metallized PET pouch shields sensitive components from static and light during shipping, ensuring they arrive in perfect condition. This versatility extends its utility far beyond traditional packaging.

Visualize a holiday gift box wrapped in PET metallized film: the shimmering surface reflects festive lights, making it a standout gift. This decorative flair, paired with practical protection, makes it a favorite for seasonal campaigns.

Why PET Metallized Film Stands Out

The rise of PET metallized film isn’t just a trend—it’s a response to real-world needs. Compared to aluminum foil, it offers similar benefits (like reflectivity and barrier protection) at a fraction of the weight and cost. Its flexibility allows for innovative designs that rigid materials can’t match, while its recyclability aligns with growing environmental concerns. Though it may not provide the absolute opacity or gas-tightness of foil, its balanced performance makes it ideal for products with shorter shelf lives or less stringent requirements.

Moreover, advancements in metallization technology continue to enhance its capabilities. For instance, varying the thickness of the aluminum layer can fine-tune its optical density, tailoring it to specific needs—be it maximum reflectivity or controlled light transmission. This adaptability ensures that PET metallized film remains relevant as industries evolve.

Challenges and Considerations

No material is without its limitations. PET metallized film, while exceptional, falls short of aluminum foil in terms of absolute barrier protection, making it less suitable for ultra-sensitive goods requiring long-term storage. Its reliance on a thin metal layer also means that scratches or damage can compromise its performance. However, these drawbacks are often offset by its cost-effectiveness and versatility, especially when paired with other materials in multilayer laminates.

The Future of PET Metallized Film in Packaging

Looking ahead, PET metallized film is poised for even greater prominence. As sustainability becomes a priority, its lightweight nature and potential for recycling will drive adoption. Innovations like biodegradable PET variants or enhanced barrier coatings could further expand its reach, bridging the gap with traditional materials. Whether it’s keeping snacks crisp, medicines potent, or cosmetics glamorous, this film is rewriting the rules of packaging—one shimmering layer at a time.

In conclusion, PET metallized film is more than just a packaging material—it’s a testament to human ingenuity, blending science and style to meet modern demands. From the grocery aisle to the pharmacy shelf, its presence is felt, proving that sometimes, the smallest layers make the biggest impact.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film ,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products