Polyethylene Terephthalate (PET) film is a widely recognized material in the packaging industry, celebrated for its remarkable combination of physical, chemical, and mechanical properties. As a thermoplastic polymer, PET film has become a staple in various applications, particularly in blister packaging for tableware. This article explores the intrinsic characteristics of PET film and delves into how these attributes make it an ideal choice for protecting and presenting disposable or reusable tableware, such as spoons, forks, knives, and trays. Through a detailed examination of its features and practical uses, we aim to highlight why PET film stands out in the competitive world of packaging materials.

Key Properties of PET Film

PET film boasts a unique set of properties that distinguish it from other plastic films like PVC or PP (polypropylene). These characteristics not only ensure functionality but also enhance the aesthetic and environmental appeal of the final product.

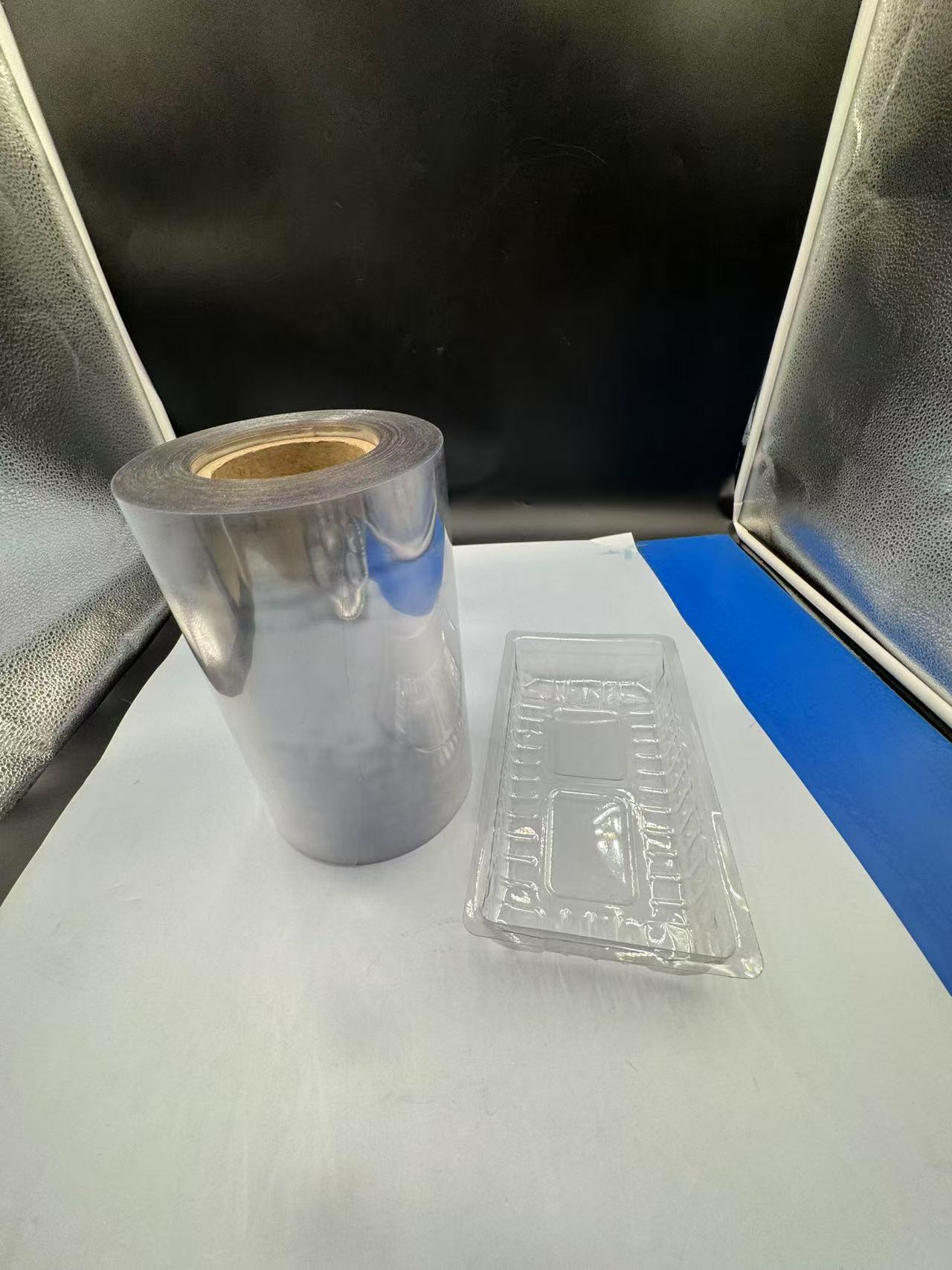

Clarity and Transparency

PET film exhibits impressive tensile strength and resistance to impact, making it highly durable. This is particularly advantageous in packaging tableware, where the film must withstand handling, stacking, and transportation without cracking or deforming. Imagine a stack of plastic forks packaged in PET film blister packs being shipped across continents—its robustness ensures that the contents remain intact, even under pressure.

Thermal Stability

With a melting point aro

PET Film in Blister Packaging for Tableware

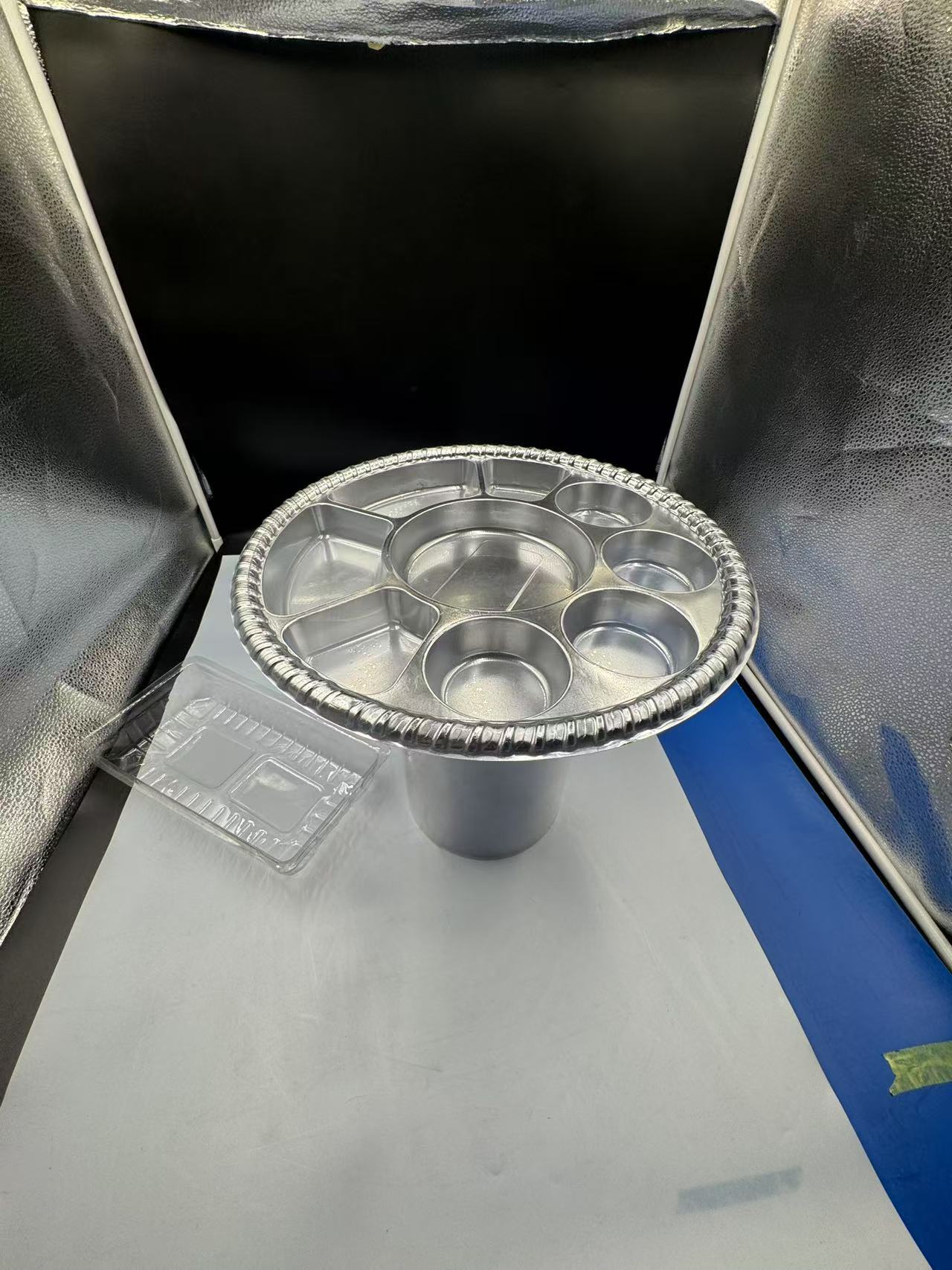

1. Thermoforming Precision

2. Protection During Transit and Display

3. Enhancing Product Visibility

The clarity of PET film transforms blister packaging into a marketing tool. Retailers often display tableware in blister packs to showcase the product’s design and quality. A set of colorful reusable spoons, for example, gains an extra layer of allure when encased in transparent PET film, allowing the vibrant hues to pop. This visibility can sway purchasing decisions, as customers feel reassured by what they see.

Consider a scenario in a department store: two packs of forks sit side by side—one in opaque packaging, the other in PET film. The latter, with its see-through quality, naturally draws more attention, as shoppers can immediately assess the fork’s shape and finish.

4. Sustainability in Action

As sustainability becomes a priority, PET film’s recyclability aligns perfectly with eco-conscious packaging trends. Brands producing disposable tableware, such as bamboo or biodegradable plastic spoons, often pair their products with PET film blister packs to maintain a green image. After use, consumers can recycle both the tableware (if applicable) and the packaging, closing the loop on waste.

A practical example might involve a company launching a line of compostable cutlery for outdoor events. By using PET film made from recycled materials, they not only protect the product but also appeal to environmentally aware customers, who appreciate the dual commitment to quality and sustainability.

5. Cost-Effectiveness and Scalability

PET film strikes a balance between performance and affordability, making it a cost-effective option for large-scale production. In the competitive tableware market, where margins can be tight, this affordability allows manufacturers to package high volumes of products—think thousands of plastic cups or plates—without compromising on quality. The film’s versatility also supports customization, enabling businesses to cater to diverse tableware designs without significant retooling costs.

For a small business entering the reusable tableware niche, PET film offers an accessible entry point. They might start with a modest run of blister-packed forks, confident that the material’s durability and appeal will support their brand’s growth.

Challenges and Considerations

While PET film excels in many areas, it’s not without challenges. Its relatively high melting point, while advantageous for stability, requires precise control during thermoforming to avoid energy waste. Additionally, though recyclable, the actual recycling rates depend on local infrastructure, which varies globally. Manufacturers must also ensure that the film’s thickness is optimized—too thin, and it compromises strength; too thick, and it raises costs unnecessarily.

Despite these hurdles, advancements in PET film technology, such as improved barrier coatings or thinner yet stronger variants, continue to enhance its suitability for tableware packaging. These innovations ensure that PET film remains a dynamic and evolving solution.

Conclusion

PET film is more than just a packaging material—it’s a cornerstone of modern blister packaging for tableware, blending functionality, aesthetics, and sustainability. Its clarity showcases products beautifully, its strength protects them reliably, and its recyclability aligns with contemporary values. From a single disposable spoon to an elegant set of reusable cutlery, PET film elevates the packaging experience, benefiting manufacturers, retailers, and consumers alike. As the demand for efficient and eco-friendly packaging grows, PET film’s role in the tableware industry is poised to expand, proving that even the simplest materials can have a profound impact.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products