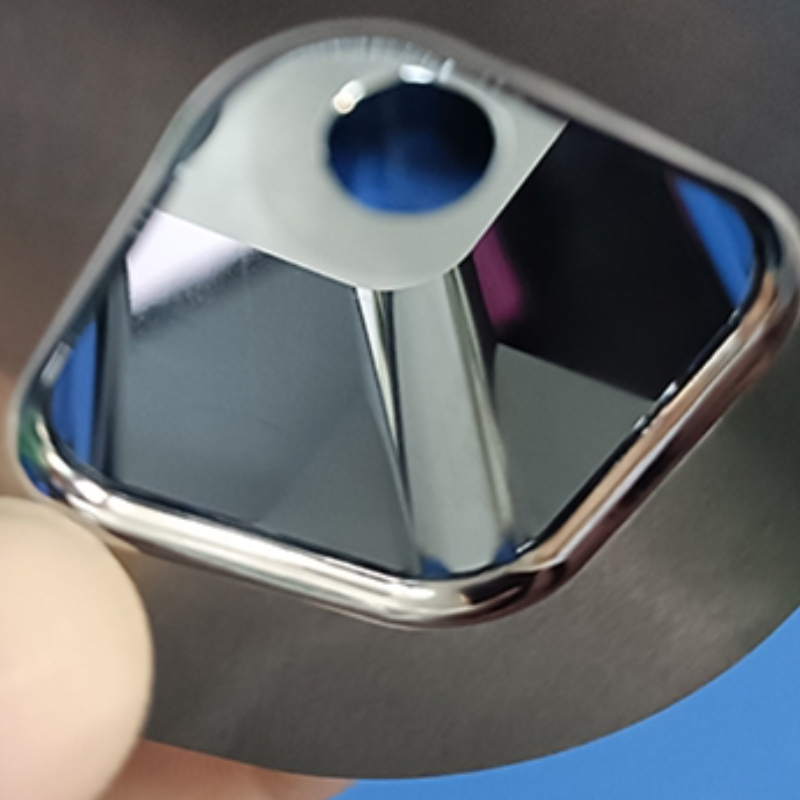

Tungsten steel square hole tensile mold is a precision mold specially designed for processing square holes or other special structures. Its design and manufacture combines the high performance of tungsten steel materials with special processes. The following is a summary of relevant information about the comprehensive search results:

1. Material selection and characteristics

1. **Material Advantages**

Tungsten steel (carbide) is made of a mixture of tungsten and steel, with the highest hardness (HRA 88-93), the highest wear resistance, the highest corrosion resistance and the highest high temperature stability, suitable for high-strength stretching scenarios. Commonly used brands include YG8, YG15, etc., which are suitable for stretching and forming materials such as stainless steel, copper, aluminum, etc.

2. **Performance Considerations**

- **Hardness and toughness balance**: High hardness ensures wear resistance, while appropriate toughness reduces the risk of impact fracture.

- **Thermal Conductivity**: The good thermal conductivity of tungsten steel helps to quickly dissipate heat and reduces thermal deformation of the mold.

2. Manufacturing process

1. **Core Steps**

According to the process description of web pages 1 and 6, the machining process of square hole stretching die usually includes:

- **Structural Design**: Design mold cavity, mold release mechanism, etc. according to square hole size.

- **Material Cutting and Rough Processing**: Cut tungsten steel and perform preliminary molding.

- **Heat treatment and finishing**: The inner wall of the square hole is processed through high-precision processes such as wire cutting and electric spark processing to ensure dimensional accuracy (the tolerance can be controlled at ±0.002mm).

- **Surface treatment**: Polish to mirror finish to reduce material adhesion; some molds require CVD coating to enhance wear resistance.

2. **Assembly Process**

The assembly of square hole molds requires special treatment:

- Use interference fit to inlay the tungsten steel die into the die sleeve, and gradually align the end faces through stamping to ensure concentricity.

- Multiple coating and assembly cycles to avoid deformation and improve life.

3. Advantages and applications of molds

1. **Performance Advantages**

- **High precision**: can process mirror-grade mold holes to ensure product surface finish.

- **Long life**: The wear resistance is more than 5 times that of ordinary molds, especially suitable for large-scale production.

- **Low coefficient of friction**: Reduce tensile resistance, improve efficiency and reduce energy consumption.

2. **Application Area**

Widely used in industries such as stainless steel tableware, electronic communication shells, automotive parts (such as engine parts), etc. that require high-precision square hole molding.

4. Maintenance and customization

1. **Maintenance points**

- Clean the mold regularly to avoid dust or corrosive media residues.

- Avoid overload use and repair worn parts in time to maintain accuracy.

2. **Customized Service**

Our company supports customization of the map and adjusting mold structural parameters according to customer needs.

Dongguan Fengguan Precision Technology Co., Ltd. is located in Changan Town, Dongguan City, which is the main center of Zhuzhou cemented carbide in Dongguan. The main tungsten carbide materials, tungsten steel mold deep processing and all kinds of tungsten steel precision accessories. The cemented carbide series mainly produced and sold are: cemented carbide tungsten steel plate, cemented carbide tungsten steel round rod, cemented carbide tungsten steel strip, cemented carbide tungsten steel round die, diamond tungsten steel, various kinds of cemented carbide tungsten steel non-standard blank, non-magnetic tungsten steel, hard alloy drawing die, tungsten steel pipe shrinking die, tungsten steel pipe drawing die, tungsten steel forming die, tungsten steel punching die, powder metallurgy die, tungsten steel sealing die, Tungsten steel insert sleeve, Tungsten steel extrusion die, Tungsten steel roll, Tungsten steel guide rail, Tungsten steel sealing ring, Tungsten steel punching and shearing die, Tungsten carbide wear-resistant parts, Tungsten wear-resistant steel, Tungsten corrosion-resistant steel, Tungsten steel conductive block, Tungsten steel punch, Tungsten steel bushing, Tungsten steel parts, cemented carbide ball, Tungsten steel milling cutter, diamond blade, Tungsten steel processing, etc. The main products are: Tungsten Steel Stretching Mold,CNC Processing Tungsten Steel Products,Tungsten Steel Die Material,Tungsten Carbide Custom Machining,Tungsten Steel Precision Machined Parts,New Energy Materials Ceramic Aluminium Oxide Zirconia。

Through reasonable material selection, precision processing and standardized maintenance, the mold insert of tungsten steel can significantly improve the mold performance and is suitable for high-precision and large-scale production scenarios. In actual application, costs and benefits need to be weighed based on specific working conditions.

Please provide the product CAD drawings you need, we will serve you wholeheartedly to solve your needs for mold accessories and other products!