In the ever-evolving world of apparel design, where creativity and functionality intertwine, printing technologies play a pivotal role in bringing artistic visions to life. Among these,

Direct-to-Film (DTF) printing, utilizing Polyethylene Terephthalate (PET) DTF transfer film, has emerged as a game-changer. This innovative medium allows designers to produce vibrant, durable, and intricate patterns on a wide range of fabrics, revolutionizing the custom clothing industry. This article delves into the characteristics of PET DTF transfer film and explores its transformative applications in clothing design, offering insights into why it has become a preferred choice for designers and manufacturers alike.

Characteristics of PET DTF Transfer Film

PET DTF transfer film is a specialized medium designed for DTF printing, distinguished by its unique properties that ensure high-quality transfers. Below are the key characteristics that make PET DTF film stand out:

1. Specialized Coating for Ink Absorption

Unlike standard PET films, PET DTF transfer film features a matte, frosted surface with a specialized ink-absorbing coating. This coating ensures that DTF inks—typically water-based CMYK and white pigment inks—adhere effectively without bleeding or smudging. The coating’s high ink-load capacity allows for sharp, detailed prints, even with fine lines or complex designs. A stable release layer within the coating facilitates easy peeling after heat pressing, ensuring clean edges and vibrant colors.

2. Hot and Cold Peel Variants

PET DTF transfer film is available in hot-peel and cold-peel variants, catering to different production needs. Hot-peel films are peeled immediately after heat pressing, ideal for high-volume production on common fabrics like cotton T-shirts. Cold-peel films, peeled after cooling, are better suited for intricate designs or specialty materials like canvas or coated fabrics, offering greater precision and durability. This flexibility enhances the film’s adaptability across various workflows.

3. High-Temperature Resistance

The PET substrate in DTF transfer film is engineered to withstand the high temperatures (typically 140–160°C) and pressures of heat pressing without curling or melting. This durability ensures consistent transfer quality, even during prolonged exposure to heat, making it reliable for industrial applications.

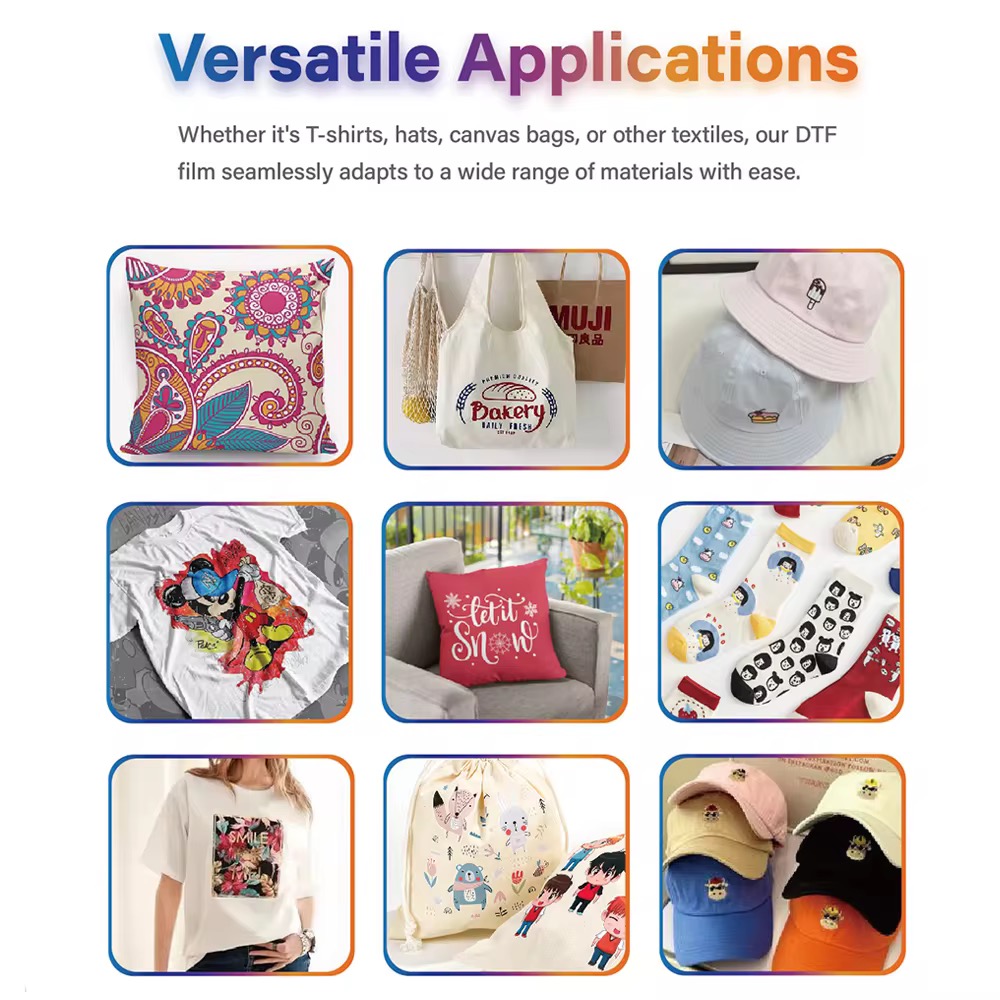

4. Versatility Across Fabrics

One of the standout features of PET DTF transfer film is its compatibility with a wide range of fabrics, including cotton, polyester, nylon, denim, spandex, and blends. Unlike sublimation, which is limited to polyester, or Direct-to-Garment (DTG) printing, which performs best on cotton, DTF printing with PET film excels on both light and dark fabrics, as well as synthetic and natural fibers. This versatility opens up endless possibilities for clothing designers.

5. Special Effect Options

PET DTF transfer film is available in various specialty variants, such as glitter, metallic, luminous, and holographic films, which add unique visual effects to designs. For instance, luminous DTF film absorbs light and glows in the dark, while metallic films create a shimmering, high-end finish. These options allow designers to push creative boundaries, offering apparel that stands out in both aesthetic and functional contexts.

6. Durability and Washability

The combination of PET DTF transfer film, DTF inks, and hot-melt adhesive powder results in prints that are highly durable. The adhesive powder bonds the design securely to the fabric, resisting cracking, peeling, or fading even after multiple washes. Reflective and metallic DTF films, in particular, maintain their shine and visual impact over time, ensuring long-lasting quality.

7. Eco-Friendly Attributes

PET DTF transfer film uses water-based inks, which are more environmentally friendly than solvent-based alternatives. Additionally, the process generates minimal waste, as excess adhesive powder can be shaken off and reused. However, the non-biodegradable nature of PET films prompts designers to consider sustainable practices, such as choosing recyclable films or optimizing production to reduce material waste.

Applications of PET DTF Transfer Film in Clothing Design

The unique characteristics of PET DTF transfer film make it an ideal tool for creating stunning clothing designs. Its applications span casual wear, sportswear, fashion apparel, and even specialty garments, offering designers unparalleled flexibility. Below are some key ways PET DTF film is used in clothing design:

1. Vibrant, Full-Color Prints for Casual Apparel

2. Specialty Effects for Fashion-Forward Designs

3. Personalized and Small-Batch Production

4. Functional Prints for Sportswear and Workwear

Reflective and high-gloss PET DTF films are widely used in sportswear and workwear for their functional properties. Reflective films enhance visibility for night runners or cyclists, while luminous films add safety features to outdoor gear. For example, a sportswear brand might use reflective DTF film to print logos on running jackets, ensuring athletes are visible in low-light conditions. The durability and washability of these prints ensure they withstand rigorous use and frequent washing.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film ,

PP Film,

Other plastic packaging products