Customized precision tungsten shafts and tungsten steel sleeves (usually made of cemented carbide, i.e. **cemented carbide**) are widely used in areas with extremely high requirements for accuracy, durability and reliability due to their highest hardness, wear resistance, high temperature resistance and excellent chemical stability. The following are its main application scope and specific scenarios:

**1. Mold and stamping industry**

- **Application Scenarios**:

- Guide columns and guide sleeves for precision molds (such as injection molds, stamping molds)

- Rotating shaft and support sleeve of stamping tool

- ** Advantages**:

High wear resistance extends mold life and reduces shutdown and replacement frequency; resistant to high pressure and impact, suitable for high-speed stamping.

**2. Automotive and Aerospace**

- **Application Scenarios**:

- High-pressure pump shaft and sleeve for engine fuel injection system

- Turbocharger rotor shaft

- Precision valve core and valve sleeve for aircraft hydraulic system

- ** Advantages**:

Resistant to high temperatures (>800°C) and corrosive media to ensure reliability in extreme operating conditions.

**3. Electronics and Semiconductor Manufacturing**

- **Application Scenarios**:

- Precision spindle and bearing sleeve for wafer cutting equipment

- Feeding shaft and guide sleeve of chip mount (SMT)

- ** Advantages**:

High precision (tolerance ±0.001mm) ensures micron-level processing stability; anti-static characteristics avoid damage to electronic components.

**4. Medical devices and precision instruments**

- **Application Scenarios**:

- Surgery robot drive shaft and transmission sleeve

- Focusing mechanism of optical instruments (such as microscopes, laser equipment)

- ** Advantages**:

Biocompatible coatings are optional and resistant to disinfectant corrosion; low friction coefficient achieves oil-free lubrication requirements.

**5. Energy and Heavy Industry**

- **Application Scenarios**:

- Wear-resistant shaft sleeves for petroleum drilling equipment

- Precision stem and sealing sleeve of nuclear power valve

- ** Advantages**:

Resistant to radiation, acid and alkali corrosion, and adapt to long-term use in harsh environments.

**6. High-end consumer goods**

- **Application Scenarios**:

- Small gear shaft of automatic winding mechanism of luxury watches

- Aperture adjustment ring sleeve for high-end cameras

- ** Advantages**:

The surface finish (Ra≤0.1μm) improves the smoothness of the operation and extends the service life.

**Applicable scenario priority**:

Tungsten steel shaft/sleeve is more suitable for **"High wear resistance + medium temperature resistance + complex load"** scenarios, while ceramics are suitable for ultra-high temperature but low impact environments, while stainless steel focuses on economy and easy processing.

**Additional instructions**

- **Precision machining requirements**: **CNC grinding + laser measurement must be used** Ensure micron tolerances and perform PVD coatings (such as TiN, DLC) when necessary to further improve surface performance.

- **Industry Trends**: With the growth of demand for precision manufacturing and miniaturization, the application of micro tungsten steel shafts (diameter <1mm) in micro motors and medical devices is growing rapidly.

Through reasonable material selection, precision processing and standardized maintenance, the mold insert of tungsten steel can significantly improve the mold performance and is suitable for high-precision and large-scale production scenarios. In actual application, costs and benefits need to be weighed based on specific working conditions.

Dongguan Fengguan Precision Technology Co., Ltd. is located in Changan Town, Dongguan City, which is the main center of Zhuzhou cemented carbide in Dongguan. The main tungsten carbide materials, tungsten steel mold deep processing and all kinds of tungsten steel precision accessories. The cemented carbide series mainly produced and sold are: cemented carbide tungsten steel plate, cemented carbide tungsten steel round rod, cemented carbide tungsten steel strip, cemented carbide tungsten steel round die, diamond tungsten steel, various kinds of cemented carbide tungsten steel non-standard blank, non-magnetic tungsten steel, hard alloy drawing die, tungsten steel pipe shrinking die, tungsten steel pipe drawing die, tungsten steel forming die, tungsten steel punching die, powder metallurgy die, tungsten steel sealing die, Tungsten steel insert sleeve, Tungsten steel extrusion die, Tungsten steel roll, Tungsten steel guide rail, Tungsten steel sealing ring, Tungsten steel punching and shearing die, Tungsten carbide wear-resistant parts, Tungsten wear-resistant steel, Tungsten corrosion-resistant steel, Tungsten steel conductive block, Tungsten steel punch, Tungsten steel bushing, Tungsten steel parts, cemented carbide ball, Tungsten steel milling cutter, diamond blade, Tungsten steel processing, etc. The main products are: Tungsten Steel Stretching Mold,CNC Processing Tungsten Steel Products,Tungsten Steel Die Material,Tungsten Carbide Custom Machining,Tungsten Steel Precision Machined Parts,New Energy Materials Ceramic Aluminium Oxide Zirconia。

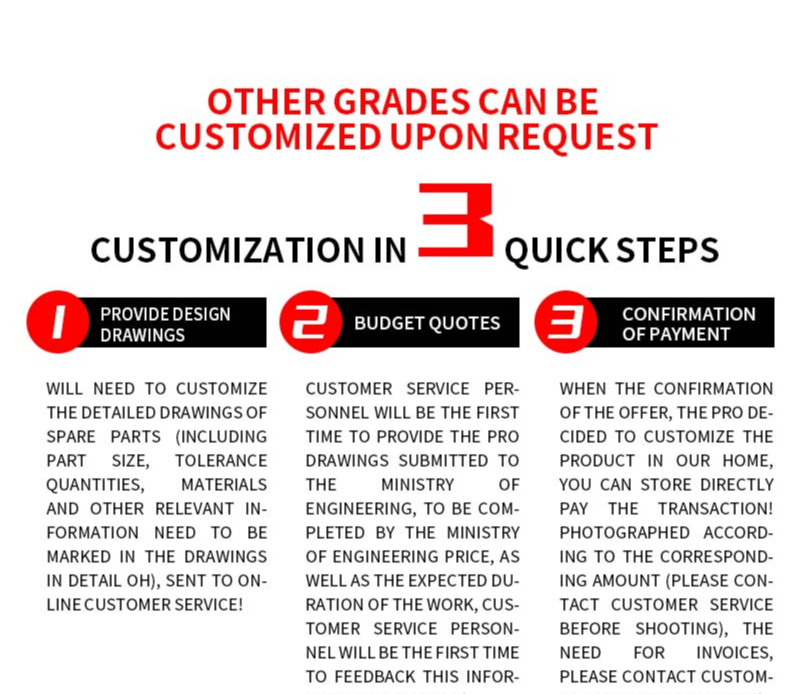

Please provide the product CAD drawings you need, we will serve you wholeheartedly to solve your needs for mold accessories and other products!