Epoxy and Polyester Powder Coating

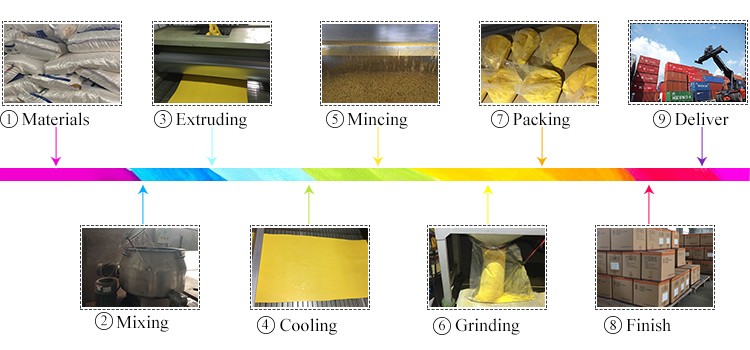

Production Processing

Characteristics and usage

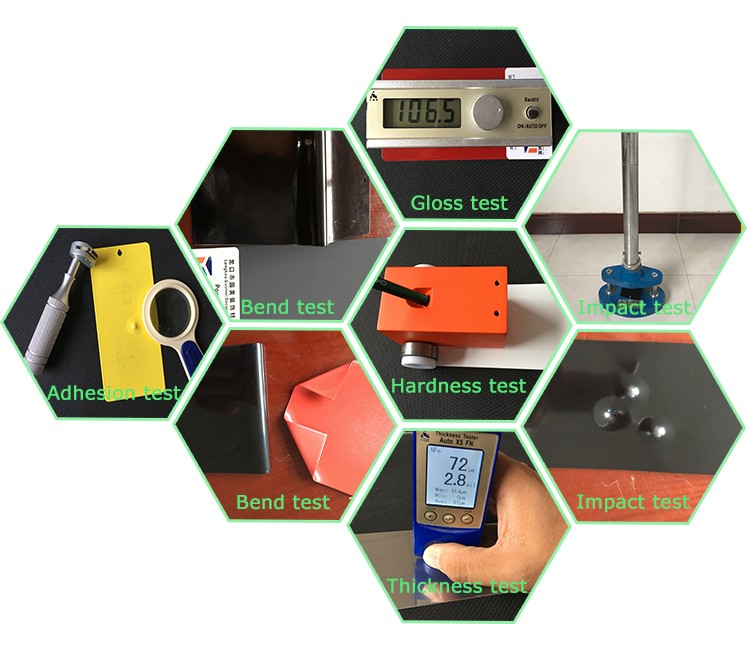

Characteristics :

1.Excellent adhesion with metal, corrosion resistance, hardness, flexibility and impact strength

2.Soluble, fusible and thermoplastic before curing.

3.Insoluble and insoluble when cured by heating

Usage :

1.General purpose:

All metal surfaces (such as refrigerators, air conditioners, car frames, etc.) that can be painted can be replaced with powder paint.

Usage

There are also Texture Powder Coating.such as Wrinkle Thermosetting Powder Coating,Hammer Thermosetting Powder Coating,Sandy Thermosetting Powder Coating,Water Wave Powder Coating,Crocodile Pattern Powder Coating.

|

MOQ

|

The minimum order is 500kg ,each color ≥ 100kg

|

|

Colors

|

RAL color :we usually use RAL colors that is widely used in paint industry and easily find in market

Color matching is available , if you have colors model ,please send to us for matching .

Now the candy color series and fluorescence color series are very popular in America and European countries.

|

|

Texture

|

Hammer,Wrinkle and other special texture.

|

|

Gloss

|

High gloss,Flat gloss,Semi- gloss

|

|

Usage

|

Houshold appliances,Toy,General industry,Automotive,Construction materials,Special function.

|

|

Samples

|

1kg powder sample is available for each color for your testing.

Sample is free of cost,but if you pay for the air freight we will highly appreciate. |

|

Prices

|

Prices depend on the colors and using environment ,for prices please tell us the colors and using environment (indoor use or outdoor use).

|

|

Time of delivery

|

Production will take about 5-8 days after receipt of prepayment,this is subject to the quantity .

|

|

Packing

|

Basic Package: 2 Plastic bags + Strong kraft carton

Custom Package: 2 Plastic bags + heat resistant bags (If customer require) + Strong kraft bag +Plastic |

|

Payment

|

T/T.

30% down payment ,70% balance before shipment.

|

Pre- treatment:

1.Steel material : oil disposing and rust removing , phosphorization treatment

2.Aluminum : derosination and chromating treatment

* Test the pre- treatment in every two hours , testing methods should in comply with the drug supplier or according to user manual of our pre- treatment

Electrostatic spray:

1.Spray distance :150-300mm

2.Spray pressure : 0.2-0.5Mpa

3.Voltage : 50-80KV

Curing conditions : 190degree * 15min (material temperature)

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Powder Coating,

Electrostatic Powder Coating,

Epoxy Resin Powder Coating,

Polyester Resin Powder Coating,

Thermosetting Powder Paint,

Solid Electrostatic Powder Coating