FAQ

1: Are you a trading company or a manufactory?

We are a manufactory, we supply the factory price with good

quality, welcome to visit !

2:Do you have QC or any safety standards for your plastic injection molding machine?

yes,we have established a highly strict quality control department to guanrantee good quality.

3:Why choose our plastic injection molding machine?

High quality with competitive price

4::How about quality control in your factory?

"Quality is first, Customers are friends".

5:Can you help us with the shipment of this machine ?

Yes , with honor ,we have our special shipment company which

already cooperate

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

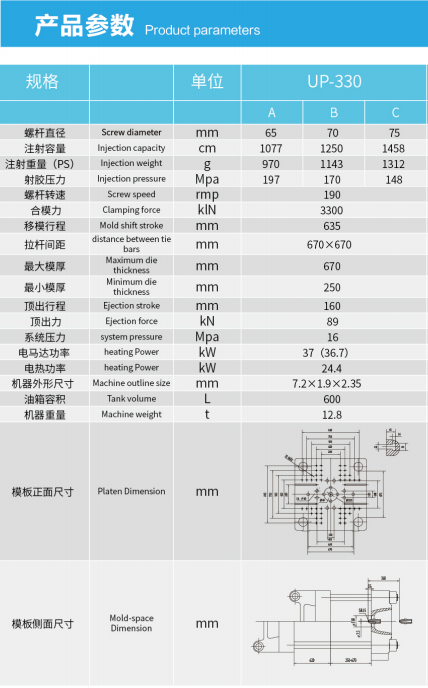

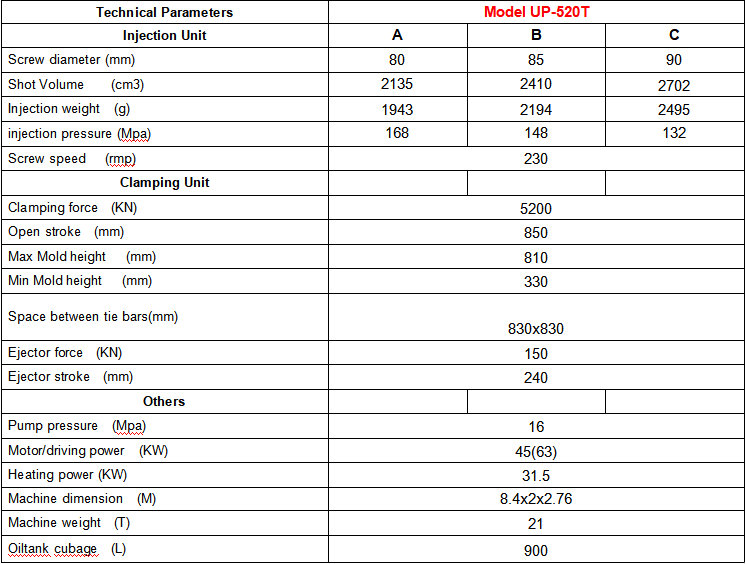

Injection Molding Machine ,

Blow Molding Machine ,

Plastic Mold ,

Blow Mold ,

Auxiliary Equipment,

Vertical Injection Molding Machine