90 meters total length

Main component of the line:

|

NO. |

name |

quantity |

|

Main roll former |

|

|

|

1 |

Un-coiler (5 tons ) |

2 |

|

2 |

Embossing and firm machine |

2 |

|

3 |

Automatic feeder and leveler (N.C) |

1 |

|

4 |

Press machine(200ton) |

1 |

|

5 |

Square mould |

1 |

|

6 |

Upper roll former |

1 |

|

7 |

Mark machine (N.C) |

1 |

|

8 |

Down panel roll former |

2(two types) |

|

9 |

Double layer construction platform |

1 |

|

10 |

Double bridge device and conveyor |

1 |

|

11 |

Other conveyor |

1 |

|

12 |

Hydraulic system |

1 |

|

13 |

Electrical control system |

1 |

|

|

|

|

|

2. PRE-HEATING SYSTEM |

|

|

|

1 |

Heating house |

1 |

|

2 |

pre-heating system |

1 |

|

3 |

electrical control system |

1 |

|

|

|

|

|

3.HIGH PRESSURE FOAM MACHINE |

|

|

|

1 |

High pressure continuous foam machine |

1 |

|

2 |

Pursing output device |

1 |

|

3 |

Electrical control system |

1 |

|

NO. |

Name |

Quantity |

|

4. DOUBLE BELT SYSTEM |

|

|

|

1 |

Double belts system(24M) |

1 |

|

2 |

Chain supporting system of two side |

1 |

|

3 |

Side-chain system |

1 |

|

4 |

Heating machine for double belts |

1 |

|

5 |

Electrical control system |

1 |

|

|

|

|

|

5. Thickness and plastic mould |

|

|

|

1 |

Mould & Plastic mould blade |

1 |

|

|

|

|

|

6. CUTTING SYSTEM |

|

|

|

1 |

Cutting saw blade |

1 |

|

2 |

Conveyor with output table |

1 |

|

3 |

Electrical control system |

1 |

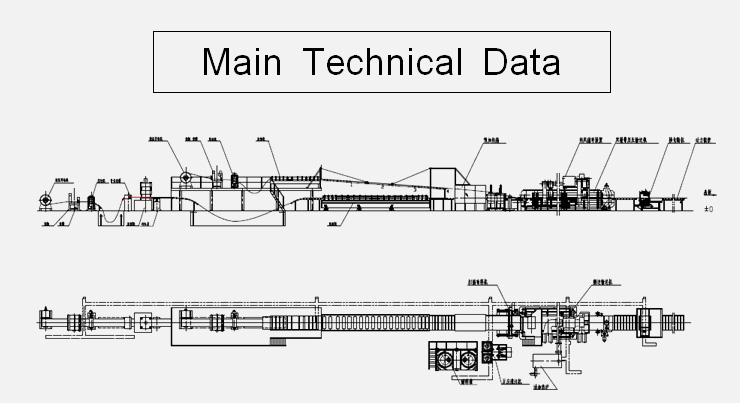

Main Technical Data

Panel Data

Facing layersmaterial: steel

Thickness to be specified

Panel type:Garage door panel

Dimensions of the final product

widthmin: 400mm

max: 600mm

Thicknessmin: 40mm

max: 60mm

Double belt length: 24m

Plant speed: max.10m/min.

min.2, 5m/min

Typical production range 4-6m/min

(Depending on foam system and cutting time)

Working height: 1.300mm

Height of production building:approx. 6m

Electrical Control System:

Temperature of production building: 15 - 35°C

Operating voltage: 380V

Operating frequency: 50Hz

control voltage: 220V

valve voltage: 24V

Signal voltage: 24V

PLC brand: Delta

| NO. | ITEM | UNIT | PARAMETERS | REMARK | |

| 1 | PANEL MATERIAL | TYPES | Pre-painted steel; Aluminum; Platinum | CUSTOMIZED | |

| Hardness | MPa |

≤350

|

|||

| Thickness | mm | 0.4-0.8 | |||

| Coil width | mm | ≤1250 | |||

| Coil ID | mm | 500.600 | |||

| Coil Weight | T | 5.8.10 | |||

| 2 | FOAM MATERIAL | EPS \ POLYURETHANE |

CUSTOMIZED |

||

| 3 |

|

m | 3-15 | ||

| 4 | Length of sandwich panel: | mm | ≤1050 | CUSTOMIZED | |

| 4 | Length of sandwich panel: | mm | ≤200 | CUSTOMIZED | |

| 5 | SPEED OF OUTPUT | m/min | 3-7 | ||

| 6 | PRESSURE OF FOAM INJECTION | bar | 150-200 | ||

| 7 |

|

m | 21 | CUSTOMIZED | |

| 8 | Controller | PLC INVERTER | |||

| 9 | Total Power | Kw | 300 | ||

| 10 | Overall dimensions | m | 110x15x5 | ||

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Roll Forming Machine,

Rolling Machine,

Roll Forming Machines ,

Forming Machines,

Rolling Shutters Machine,

Shutters Machines