Pin milling and turning are two different metal processing methods, and their application in automobile parts manufacturing also has its own emphasis. Here are the main differences between them:

Processing object:

Pin milling: Mainly used for machining holes, especially pin holes, which are used to connect and position parts.

Turning: mainly used for processing shaft parts, such as shafts, gear shafts, crankshafts, etc., and disc parts, such as the inner and outer circle, end face and thread of disc parts.

Processing method:

Pin milling: The use of special milling tools, such as end milling cutter, boring cutter, etc., in the CNC milling machine for hole processing.

Turning: Using a turning tool to process the inner and outer circle, end face and thread of shaft parts on a CNC lathe.

Accuracy requirements:

Pin milling: The accuracy of the hole is higher, usually requires a high-precision CNC milling machine and strict process control.

Turning: The precision requirements for shaft parts are also very high, requiring high-precision CNC lathes and stable cutting parameters.

Scope of application:

Pin milling: Suitable for automotive parts requiring precise hole machining, such as engine blocks, transmission housings, etc.

Turning: Suitable for automotive parts that require precise machining of shaft and disk parts, such as engine crankshaft, gear shaft, etc.

Processing efficiency:

Pin milling: For hole processing, CNC milling machine can achieve efficient multi-axis linkage processing, improve production efficiency.

Turning: For the processing of shaft and disk parts, CNC lathes can realize continuous automatic processing and improve production efficiency.

Application scenario:

Pin milling: widely used in the assembly and connection of automotive parts, such as pin holes for fixing and positioning parts.

Turning: Widely used in the transmission and support of automotive parts, such as shafts and gear shafts for transmitting power and torque

Company profile

Our company mainly provides CNC machining services CNC machining metal plastic turning parts lathe machining services CNC milling, CNC turning, sheet metal,3D printing and so on

Certificate

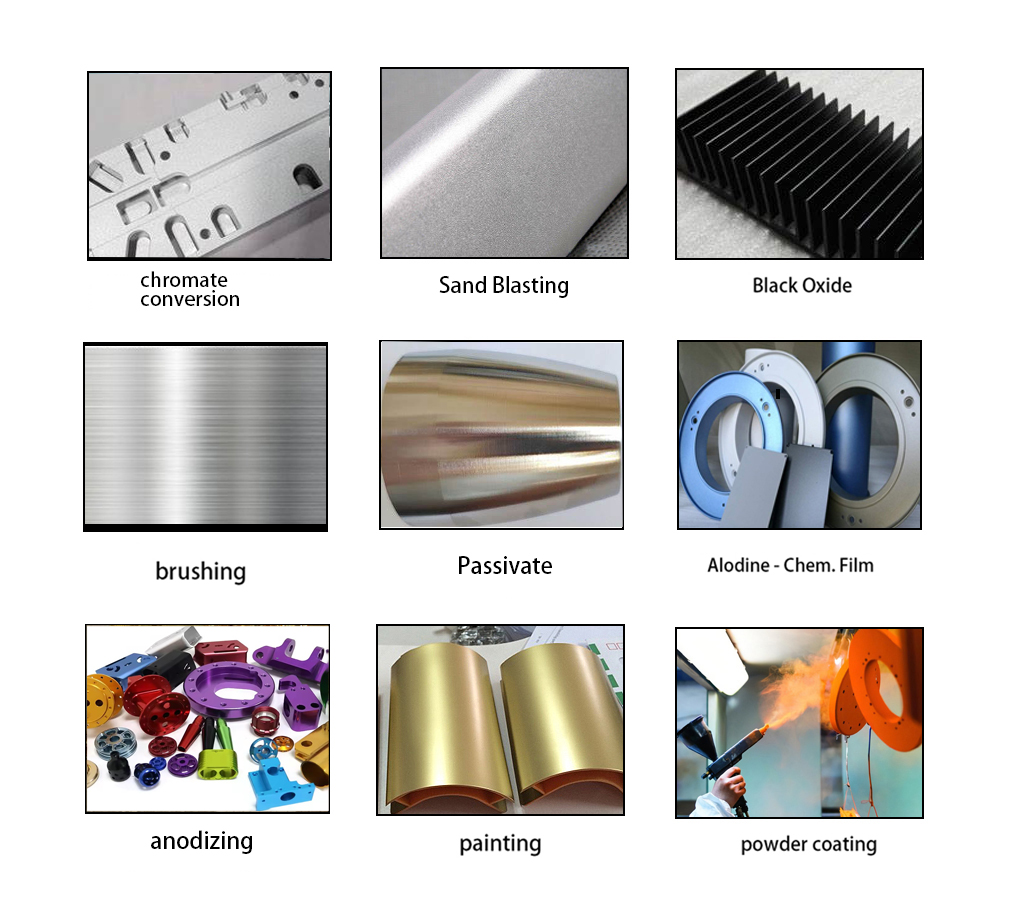

Surface treatment

Packing and shipping

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

CNC Machining,

Sheet Metal,

Injection Moulding ,

Machining Service ,

Custom Cnc Machining,

Rapid Prototyping