Air separation oxygen plant equipment is a device that uses the principle of pressure swing adsorption and uses molecular sieve to extract oxygen from the air.

The adsorption tank of the pressure swing adsorption oxygen generator, when the pressure is high, the molecular sieve absorbs nitrogen in the air, and the oxygen that is not easily adsorbed becomes a product; when the pressure is low, the nitrogen is desorbed from the molecular sieve. Using changes in pressure, the required oxygen can be effectively separated from the air.

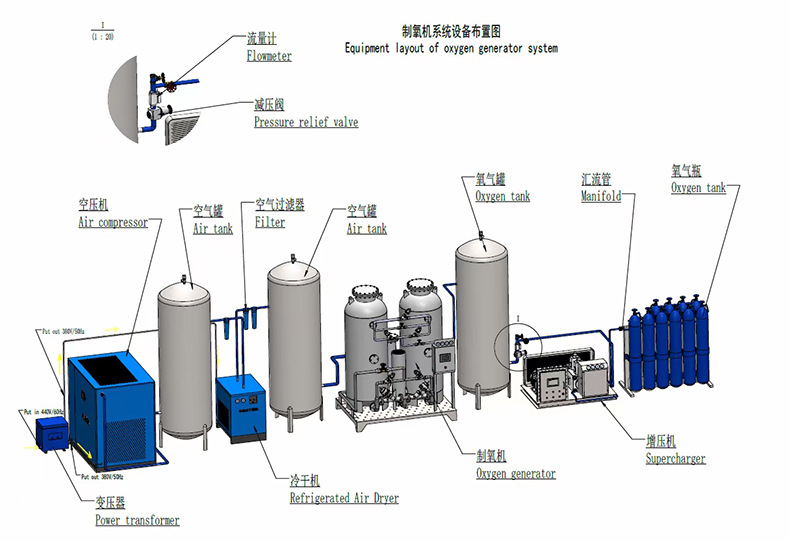

The oxygen plant uses a gas separation process to separate nitrogen and oxygen in the air to produce oxygen. The purified qualified compressed air enters the adsorption tower from the bottom of the tower, and flows through the entire tower body from bottom to top. Since the adsorption tower is filled with molecular sieves, molecular sieves are specially treated carbon molecular sieves whose pores are within the diameter range of nitrogen and oxygen. When the gas passes through, due to the different molecular diameters, nitrogen molecules are adsorbed on the surface of the molecular sieve more than oxygen molecules, and most of the oxygen molecules are in a free state and flow out from the upper end of the adsorption tower. After a period of time, the molecular sieve is saturated with the adsorbed nitrogen molecules and needs to be regenerated. The regeneration is achieved through decompression and desorption. Since molecular sieves can no longer adsorb gas molecules at low pressure, most of the molecules are evacuated when the pressure is reduced. This process is called desorption. In order to achieve continuous gas supply, one tower is in the working adsorption state; the other tower is in the regeneration state, preparing for the next adsorption. The whole process is commanded by the controller, and automatic production is realized under normal conditions.

⒈The equipment is simple, the volume is small, and the oxygen production cost is low.

⒉Easy to operate, adopt automatic program control, low operation and maintenance costs.

1. Model and parameters of movable oxygen plant Specification: MNPO-20

Oxygen purity: ≥93%±2

Oxygen pressure: <0.3Mpa

2. Compressed air index

Flow rate: ≥20Nm3/h

Pressure: ≥0.8Mpa

Temperature: ≤45℃

Containing oil: <0.003mg/m3

3. Power supply: 380V/50Hz 220V/60Hz

1. Reply in 24 hours.

2. Customized oxygen plant. And stamping is accepted.

3. Every oxygen plant will be tested before the delivery.

4. Delivery on time and excellent after-sales service.

5. High quality, reliable cost.

6.Video installation instructions, after-sales maintenance and repair.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PSA Oxygen Generator,

VPSA Oxygen Generator ,

Cryogenic Oxygen Generator,

Nitrogen Generator,

Air Compressor ,

Air Dryer