Company profile

Our company mainly provides CNC machining services CNC machining metal plastic turning parts lathe machining services CNC milling, CNC turning, sheet metal,3D printing and so on

Certificate

Automotive parts machines process a wide variety of materials, and the choice of these materials depends on factors such as the specific application of the parts, performance requirements, cost and sustainability. Here are some commonly used materials:

Steel material:

Low carbon steel: has good mechanical properties and welding properties, often used in body structure, chassis components, etc.

Medium carbon steel: high hardness, suitable for manufacturing gear, crankshaft, connecting rod and other parts to withstand higher loads.

Alloy steel: has better strength and wear resistance and is often used in the manufacture of engine components and drivetrain components.

Stainless steel: good corrosion resistance, used for external decorative parts and some parts with high corrosion resistance requirements.

Aluminum alloy:

Aluminum alloy has low density and good thermal conductivity, and is often used in the manufacture of engine parts, wheels, body panels, etc., to reduce vehicle weight and improve fuel efficiency.

Copper alloy:

Copper has good electrical and thermal conductivity and is often used in components such as electrical connectors and radiators.

Magnesium alloy:

Magnesium alloys are the least dense of all structural metals and are used to make car seats, dashboards and other components to reduce weight.

Titanium alloy:

Titanium alloys have high strength, low density and excellent corrosion resistance, and are often used in the manufacture of high-performance automotive engine components and unsprung mass components.

Plastics and synthetic materials:

Including polypropylene, ABS, polyamide (nylon), etc., for the manufacture of interior parts, air filters, fuel system components.

Composite materials:

Such as carbon fiber composite materials, with high strength and low weight characteristics, used in the manufacture of high-end car seats, body panels and spoilers.

Ceramic material:

Ceramic materials are resistant to high temperature and wear and are used in certain high-performance engine components, such as turbochargers.

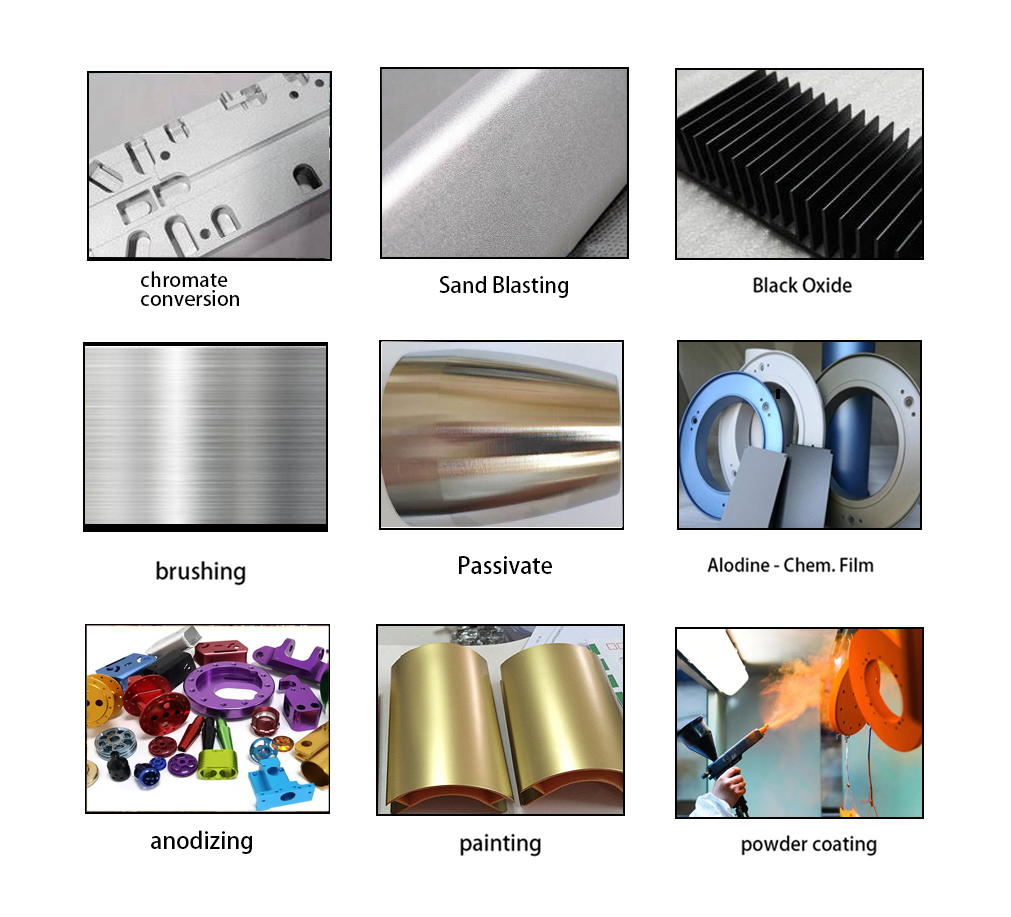

Surface treatment

The surface treatment after turning mainly includes grinding, polishing, deburring, electroplating, chemical treatment, anodizing, coating and heat treatment, etc. These methods can improve the corrosion resistance, wear resistance, aesthetics and mechanical properties of the workpiece.

Packing and shipping

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

CNC Machining,

Sheet Metal,

Injection Moulding ,

Machining Service,

Custom Cnc Machining,

Rapid Prototyping