Application of decorative aluminum profiles

Decorative aluminum profiles are widely used in the building decoration industry. Here are some specific application areas:

1. Architectural decoration: Decorative aluminum profiles can be used for doors, windows, curtain walls, interior and exterior wall decoration, etc. It comes in rich colors and diverse shapes to meet various design requirements.

2. Home decoration: Decorative aluminum profiles can be used for home decoration such as furniture, kitchens, and bathrooms. Its corrosion resistance, wear resistance and easy cleaning make it widely used in home decoration.

3. Commercial facilities: Decorative aluminum profiles can also be used for decoration in commercial facilities, such as shops, hotels, offices, etc. Its high-end appearance and durability make it widely used in commercial facility decoration.

4. Public facilities: Decorative aluminum profiles can also be used for decoration of public facilities, such as parks, squares, sports venues, etc.

5. Transportation: Decorative aluminum profiles can also be used for interior and exterior decoration of transportation vehicles, such as cars, trains, ships, etc.

6. Industrial products: Decorative aluminum profiles can also be used for decoration of various industrial products, such as mechanical equipment, electronic equipment, etc.

In general, decorative aluminum profiles are widely used in various fields due to their excellent physical and chemical properties and decorative effects.

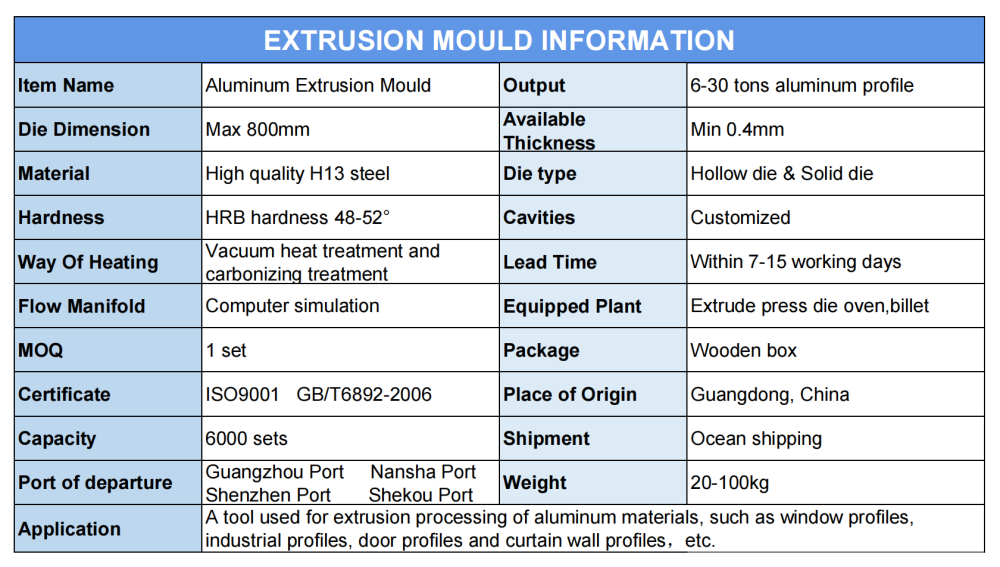

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

Classification of Aluminum Extrusion Dies

1. Classified by the section shape of the die hole compression zone

It can be divided into: flat die, conical die, flat cone die, streamlined die and double cone die, etc.,

2. Classified by the types of extruded aluminum profiles.

It can be divided into bar molds, ordinary solid profile molds, wall panel molds, variable-section profile molds, pipe molds, and hollow profile molds.

3. Classified by the number of die holes

It can be divided into single-hole die and multi-hole die;

4. Classified by the extrusion method and process characteristics

It can be divided into hot extrusion die, cold extrusion die, hydrostatic extrusion die, reverse extrusion die, continuous extrusion die, water cooling die, wide expansion die, horizontal extrusion Machine molds and vertical extrusion machine molds, etc.

5. Classified by the mold structure

It can be divided into integral mold, hollow die, removable mold, movable mold, tongue-shaped combined mold, plane split combined mold, embedded mold, fork mold, front mold, protective mold, etc.

6. Classified by the shape and structure of the mold

It can be divided into a cone mold with an inverted cone, a cylindrical mold with a boss, a cone mold with a positive cone, a conical-middle cone ring mold with an inverted cone, and an inverted cone mold. Cylindrical-conical molds for cones, reinforced molds, etc.

Quenching Furnace

The quenching furnace is a furnace that heats the workpiece before quenching.

Quenching is to put the workpiece into the furnace and heat it to the quenching temperature above the critical point and keep it for a period of time, then quickly take the workpiece out of the furnace and put it into the quenching liquid (oil or water) for quenching.

The heat source of the furnace can be electricity and fuel, and the temperature can be measured by a thermocouple.

Furnaces using electricity, gas, and liquid fuels can be automatically controlled and regulated by instruments.

Our quenching standard:

After heat treatment for 14 hours, the hardness reaches 50-52 degrees.

Tempering Furnace

The tempering furnace is used for tempering general metal parts in air and quenching, annealing and aging heat treatment for aluminum alloy die-casting parts, pistons, aluminum plates and other light alloy parts.

The shell is welded by steel plate and section steel, and the trolley is welded by section steel and steel plate.

The trolley can reduce heat radiation and convection loss through soft contact with the furnace lining and sand sealing mechanism, and effectively ensure the sealing of the furnace body.

(Our tempering standard: 2 times*10 hours)

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Industrial Aluminum Material,

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile