Overview of PVC Use in Insulation Applications

Introduction

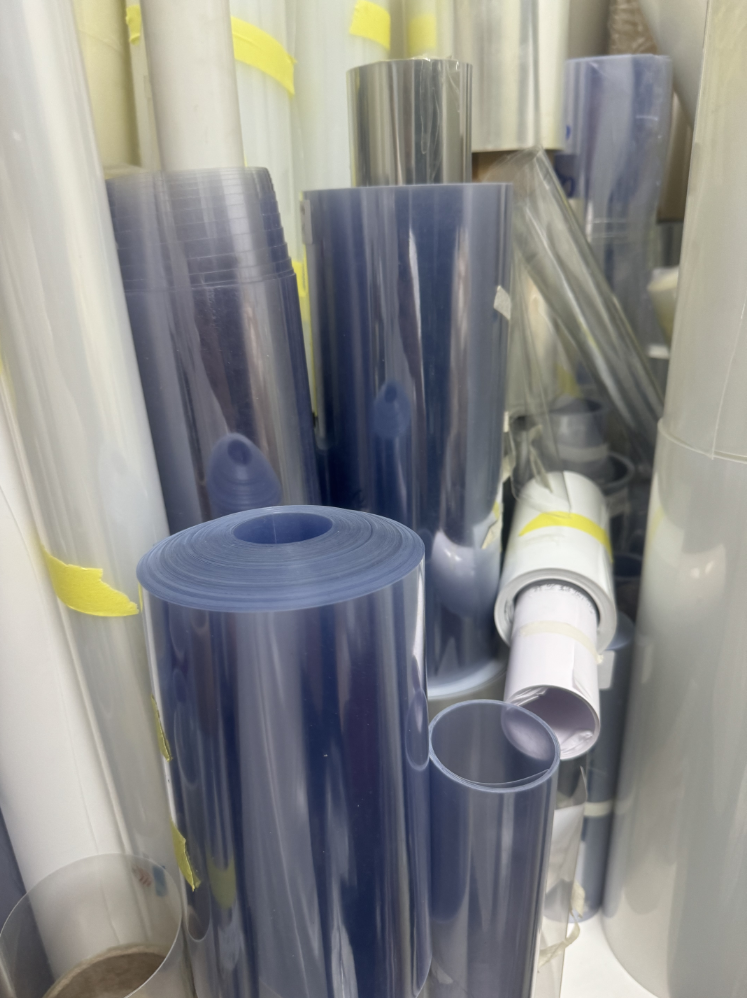

Given the very different capabilities of PVC, it has enormous usage in construction, health, automotive, and electronics industries. Among these usages, insulation is very important for PVC usages in electrical cables, wires, and other kinds of insulation. The properties that make this material a good insulator, advantages, and applications all across the board are discussed in this paper.

Properties of PVC Used for Insulation

The popularity of PVC as an insulation material results from its peculiar set of properties, which include the following:

1. Thermal Stability: The most important property of PVC used as insulation material relates to its excellent thermal stability. It withstands a wide temperature range without degradation and hence finds its application in both high and low-temperature applications.

2. Electrical Insulation: PVC has inherent electrical insulating properties that make it very suitable for insulation in electric cables and wires. This makes sure there is no possibility of currents leaking from the conductor to the surroundings; hence, safety and efficiency.

3. Durability: Since PVC is so strongly resistant to wear and tear caused by these elements, such as moist conditions, chemicals, and UV radiation, the durability attributed gives an extended life to PVC-insulated materials even in hostile environments.

4. Flame Retardancy: This is one of the most important PVC properties—its flame retardancy. PVC does not ignite very easily; it can self-extinguish if the source of the flame is removed. It is by virtue of this property that PVC offers safety in insulation applications, more so in those setting where fire safety may be under threat.

5. Flexibility: Depending on the additives used during its manufacture, PVC can be produced to have different levels of flexibility. The flexible PVC is highly applicable in applications that involve bending and taking different shapes without cracking.

6. Cost-Effectiveness: Compared to other materials used for insulation, PVC is relatively cheap. Because of its cost-effectiveness and impressive properties, it creates a favorite basis upon which many industries operate.

Applications of PVC in Insulation

The flexibility of PVC makes this material very applicable in a great number of insulation works within numerous industries:

1. Electrical Wiring and Cables: The biggest single application of PVC for insulation in terms of usage is in the electrical industry. PVC coats insulation of electrical wires and cables to make them safe for conducting electricity without any chance of short circuits and shocks. PVC-insulated cables are used in residential, commercial, and industrial building projects.

2. Construction: In the building and construction industries, PVC is applied as insulation in building envelopes. It can be used in windows, doors, and roofing membranes to provide thermal insulation that helps to regulate indoor temperatures, hence making them energy-efficient.

3. Automotive Industry: PVC is used in insulation of electrical components and wiring systems of vehicles in the automobile industry. Since the material is very durable and resistant to many chemicals and oils, it is suitable for use in automotive insulation.

4. Appliances and Electronics: PVC insulation is used with many domestic appliances and electronic devices to protect internal wiring and components. PVC prevents electrical faults and allows these devices to work safely.

5. Telecommunications: In the industry associated with telecommunications, PVC is used to insulate cables carrying data and signals. It has excellent electrical insulation properties that guarantee a clear transmission without interference.

Environmental Considerations

Though PVC has several advantages as an insulation material, there are some environmental concerns about its production and disposal. Making PVC requires chlorine, and if the process is not properly done, dangerous byproducts may be formed. Besides, it is not biodegradable, and this causes problems with waste disposal.

However, breakthroughs in recycling technologies have successfully recycled PVC, minimizing its impact on the environment. A number of companies that produce PVC with lower environmental footprints are using recycled content and increasingly developing more sustainable production processes.

Conclusion

PVC has proven to be an effective material with extremely high applicability for insulation, considering its excellent thermal stability, electrical insulation, durability, and cost-effectiveness. The areas of application of this material are found in many industries: electrical, construction, automotive, and telecommunications. Although there are environmental considerations to be taken into account, ongoing developments in recycling and sustainable methods of production offset these concerns to some degree. With technology and materials science striding ever further into the future, PVC will probably remain one of the main insulation materials for many years to come.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film ,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products