Mc Nylon Pa66 Plastic Gear

Ingenious design and equipment products are enough for a strong life, use quality products,

high quality, craftsmanship, quality products, smooth operation, quality products, thick

materials, quality equipment products.

Gear Products Descriptions:

(1)According to the different strength and performance, we choose the plastic with strong

compression;

(2)Using Germany professional software and our professional engineers to design productswith

more reasonable size and better performance;

(3)We can customize our products according to the needs of our customers,Therefore the

optimal performance of the gear can be exerted under different working conditions;

(4)Quality assurance in every step to ensure product quality is controllable.

Products

Gear Products

Module

M0.5-M10

Precision grade

DIN6, DIN7, DIN8, DIN10

Pressure angle

20 degree

Material

C45 steel, Stainless steel 304, Plastic, Brass, 20CrMo,40Cr and so on

Heat treatment

Hardening and Tempering, High Frequency Quenching,Carburizing etc

Surface treatment

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating

Application

Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems. Automated warehousing systems.

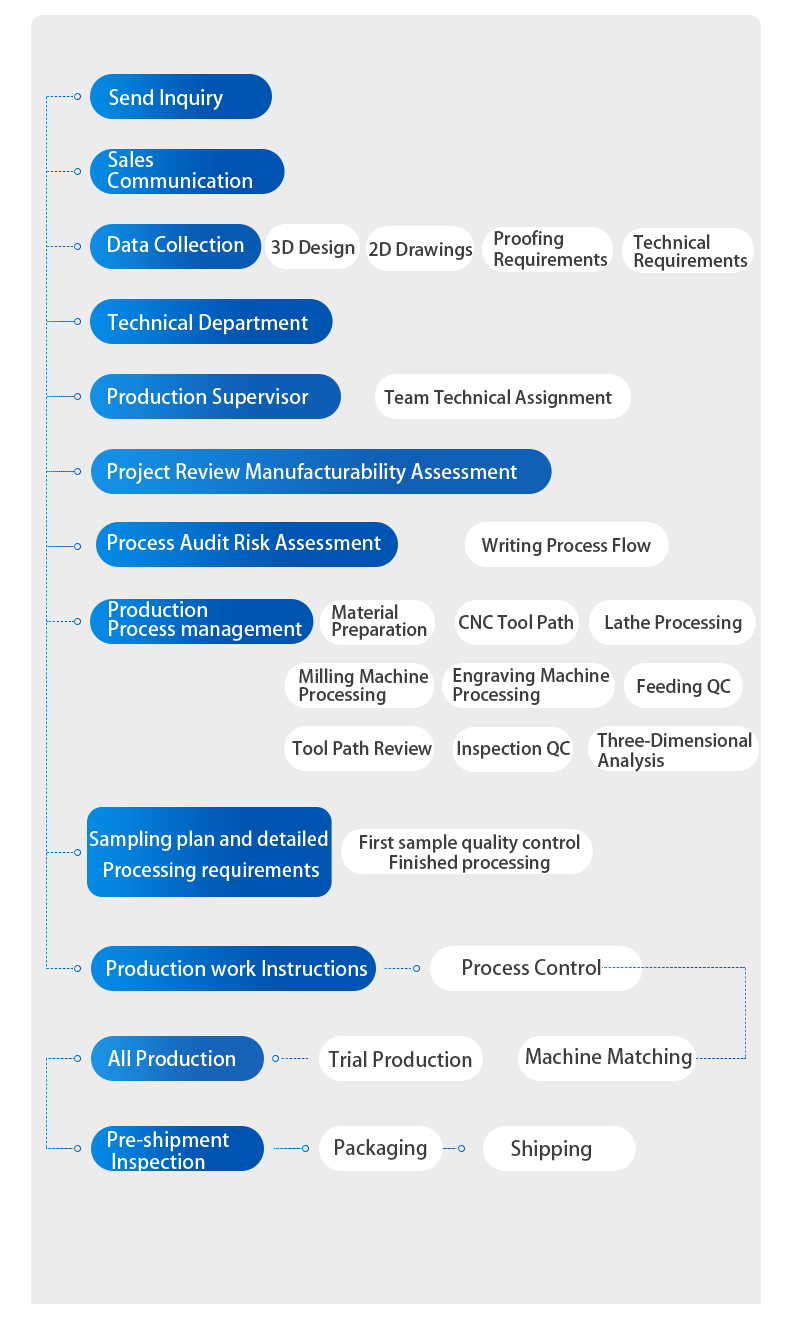

Machining process

Hobbing, Milling, Drilling, Shaving, Grinding

CNC Machining Parts Materials used in plastic gears are, in general, engineering plastics such

as polyacetal (POM) and MC Nylon which is essentially polyamid resin. In addition, U-PE and

PEEK can be used.

When there is a large temperature fluctuation in the application environment, when the diameter

is large or when there is load on its keyway, metal hub made of S45C or stainless steel may

sometimes be used. In these cases, the teeth portion and the hub portion are attached together

with screws. If it is not possible to screw together, two parts are fused together and made into

fused gears. KHK’s fused gears are designed in such a way that the holding strength of the

fused surface is stronger than the tooth strength.

The positive characteristics of plastic gears include being lightweight, non-rusting, quiet, injection

molding enabling low cost and large production, and able to operate without lubrication by mating

with metal gears. On the other hand, low strength, tendency to hold heat, large dimensional

change including backlash compared to metal, etc. are some of the points requiring caution.

The degree of dimensional changes that occur with plastic gears depend on the ability to

resist temperature change, moisture absorption rate and resistance to chemicals.

As far as the applications of plastic gears, they are used in varying industries such as food

production machines, consumer electronics, chemical, toy, and medical equipment industries.

For CNC machining, the products will be sent for 3 days. And we support OEM and ODM.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

CNC Machining Parts,

Injection Molding Parts ,

Plastic Sheets,

Plastic Tubes,

Plastic Rods,

Peek Sheet