Title: The Characteristics and Packaging Applications of Transparent PETG Shrink Film

Abstract: This article comprehensively explores the characteristics and various packaging applications of transparent PETG shrink film. It elaborates on its outstanding visual appearance, excellent protection capabilities, remarkable barrier properties, favorable environmental performance, adjustable shrinkage rate, diverse thickness and width options, and its wide-ranging use in multiple industries. Through a detailed analysis, it is demonstrated that PETG shrink film is an ideal choice for modern packaging, providing both functionality and aesthetic appeal.

I. Introduction

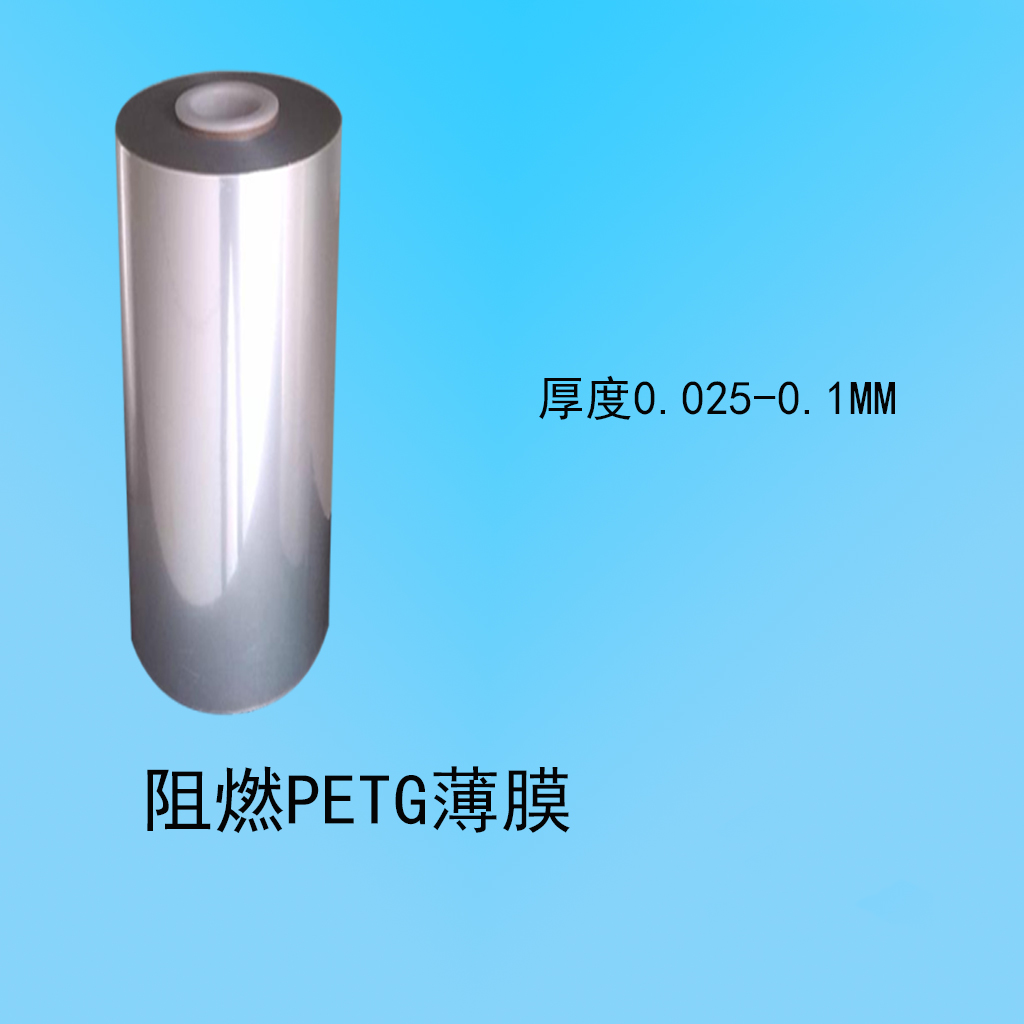

II. Characteristics of Transparent PETG Shrink Film

B. Protection Function

C. Barrier Properties

D. Environmental Performance

E. Shrinkage Rate

F. Thickness Options

G. Width Range

III. Packaging Applications of Transparent PETG Shrink Film

A. Food and Beverage Industry

B. Daily Chemical Products

C. Pharmaceutical Industry

D. Electronic Industry

E. Hardware Industry

In the hardware industry, PETG shrink film is used to package a variety of tools and metal products. Screwdrivers, wrenches, and other hand tools are often packaged with this film to protect them from scratches and corrosion. The film's strength and resistance to wear make it suitable for withstanding the rigors of storage and transportation. The barrier properties prevent moisture and oxygen from reaching the metal surfaces, thereby reducing the risk of rusting. The shrinkage rate ensures a tight fit, keeping the tools in place and presenting them in an organized and visually appealing manner.

IV. Conclusion

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film ,

PP Film,

Other plastic packaging products