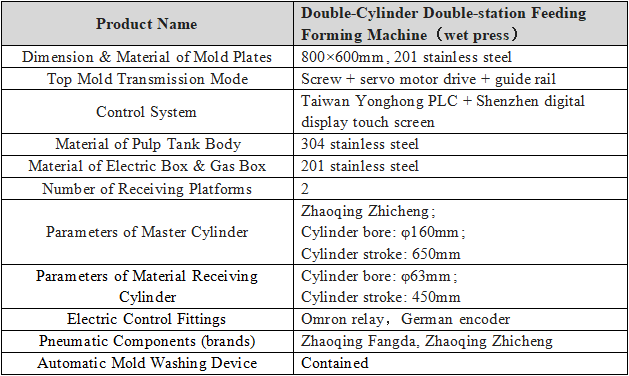

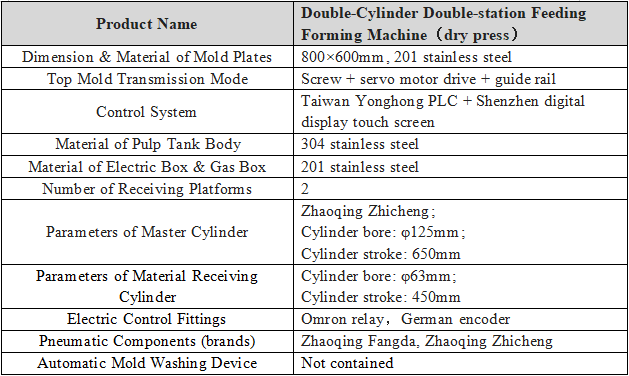

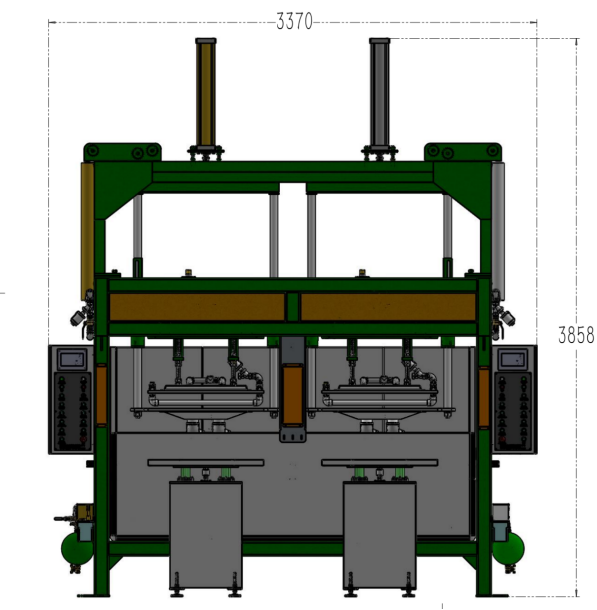

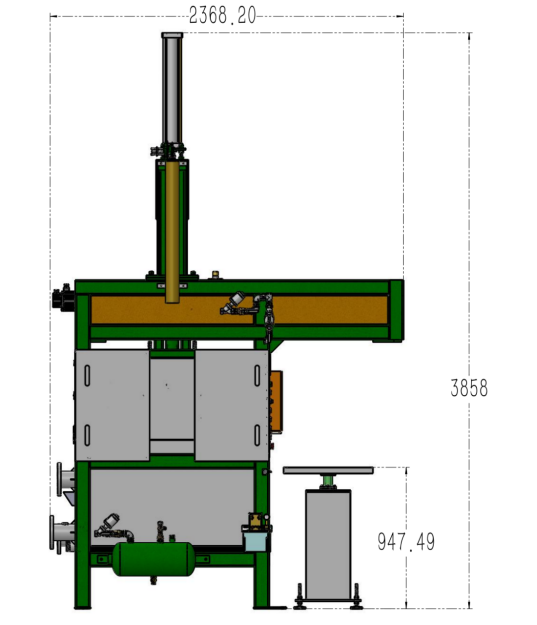

The equipment has two stations, so that it can produce two different shapes and thicknesses of products at the same time. Its working principle is to use pulp as raw material, through vacuum adsorbing the pulp to the mold and adjusting the time of pulp suction to ensure that the products reach a certain thickness and dry-wet ratio; then after the mold transfer, demolding and other processes, paper tray products are finally molded.

This forming machine adopts servo motor+screw guide rail to send out the products and place them on the receiving platform, in order to reduce the labor intensity of workers and improve the production efficiency; through PLC and touch screen control, the production speed can be adjusted according to the needs of different products. With good performance and high production efficiency, this machine is very widely used in pulp molding industry.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Automatic forming and shaping integrated machine,

Double-cylinder double-station forming machine,

Servo oil pressure shaping machine,

Servo oil pressure edge trimming machine ,

Intelligent pulp making system,

Vacuum tank