Applications of Polycarbonate Sheets in Sunroom and Other Renovation Projects

Polycarbonate sheets have recently been used a lot in the construction and renovation business in relation to the development of sunrooms. This happens because of its special properties, which include durability, transparency, and versatility. In this essay, we shall look at the different advantages of PC sheets in the construction of sunrooms and other renovation works.

Durability and Strength

High durability is one of the major reasons for using polycarbonate sheets in construction. The PC sheet is, in fact, unbreakable and has very high resistance to impact, which makes it useful in places that need a strong and long-lasting material. In contrast to glass, which shatters under impact, polycarbonate sheets are more reliable and safe. This aspect is very important, particularly in sunrooms, where huge sheets of any material continuously stay exposed to the elements and possible flying objects.

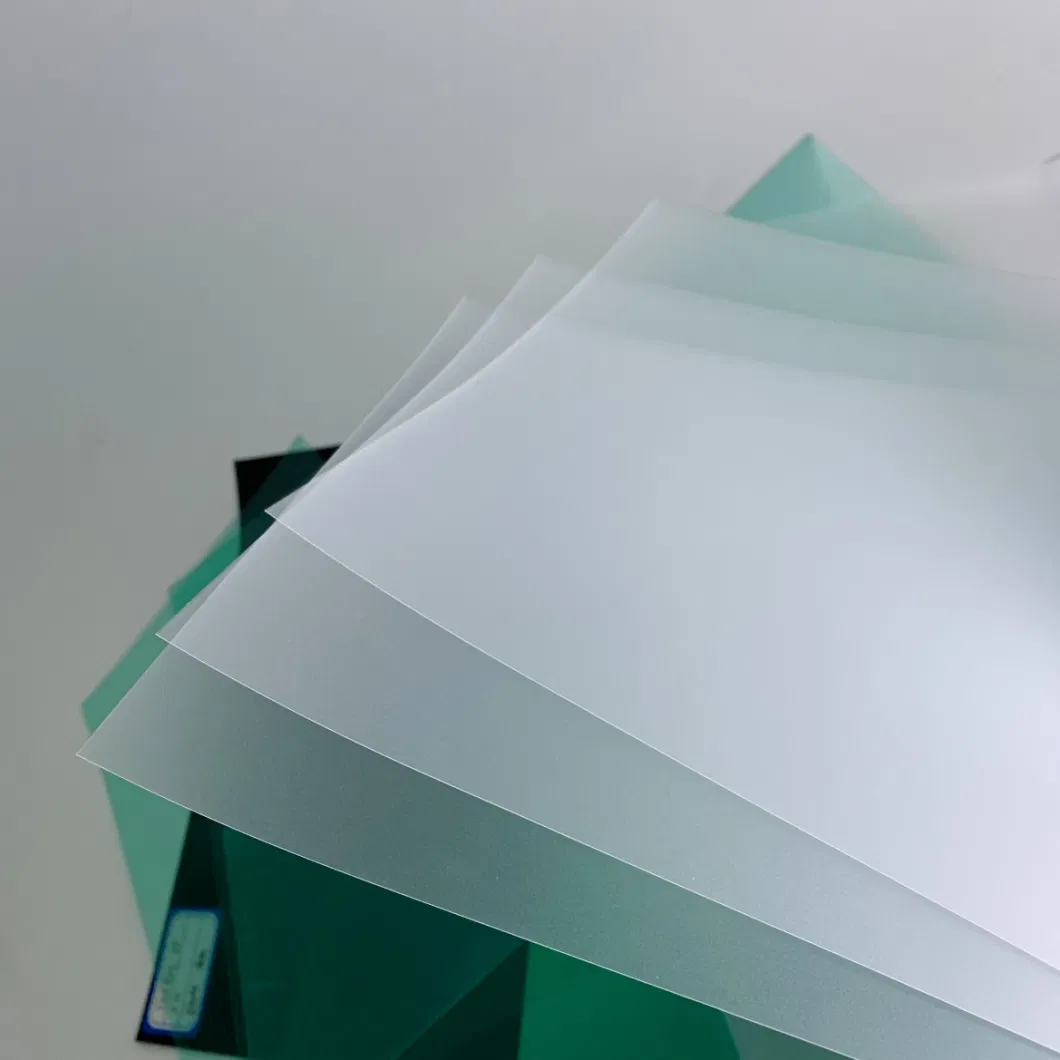

Transparency and Aesthetics

Polycarbonate sheets are highly transparent, transmitting maximum light while filtering out the worst of the UV. This is the reason that makes them quite ideal for use in sunrooms, designed majorly to let in generous amounts of natural light. PC sheets give a level of clarity, and because of that, the sunroom will remain well-lit and inviting, offering comfort and joy in relaxing and spending time there. Moreover, PC sheets are available with several coatings to enhance their aesthetic appeal with anti-glare or tinting options depending on the design requirement.

Performance

1: excellent physical and mechanical properties.

2: Excellent impact resistance, high tensile strength, bending strength and compression strength; Small creep and stable size.

3: has good heat resistance up to 125 degrees and low temperature resistance minus 45 degrees, in a wide temperature range with stable mechanical properties, dimensional stability, electrical properties and flame retardant, can be used in -60~120ºC for a long time; There is no obvious melting point and it is molten at 220-230ºC. Because of the high rigidity of molecular chain, the viscosity of resin melt is high

4: small water absorption, small shrinkage, high dimensional accuracy, good dimensional stability, small film permeability; It is a self-extinguishing material;

5: stable to light, but not uv light, good weather resistance; Oil resistance, acid resistance, resistance to strong alkali, oxidizing acid and amine, ketone, soluble in chlorinated hydrocarbons and aromatic solvents, easy to cause hydrolysis and cracking in water for a long time, the disadvantage is due to poor fatigue strength, easy to produce stress cracking, poor solvent resistance, poor wear resistance.

|

Thickness

|

0.5mm 0.125,0.25,0.375,1mm

|

|

Width

|

915mm,1000mm

|

|

Standard size

|

915mm*1830mm,1000mm*2000mm

|

|

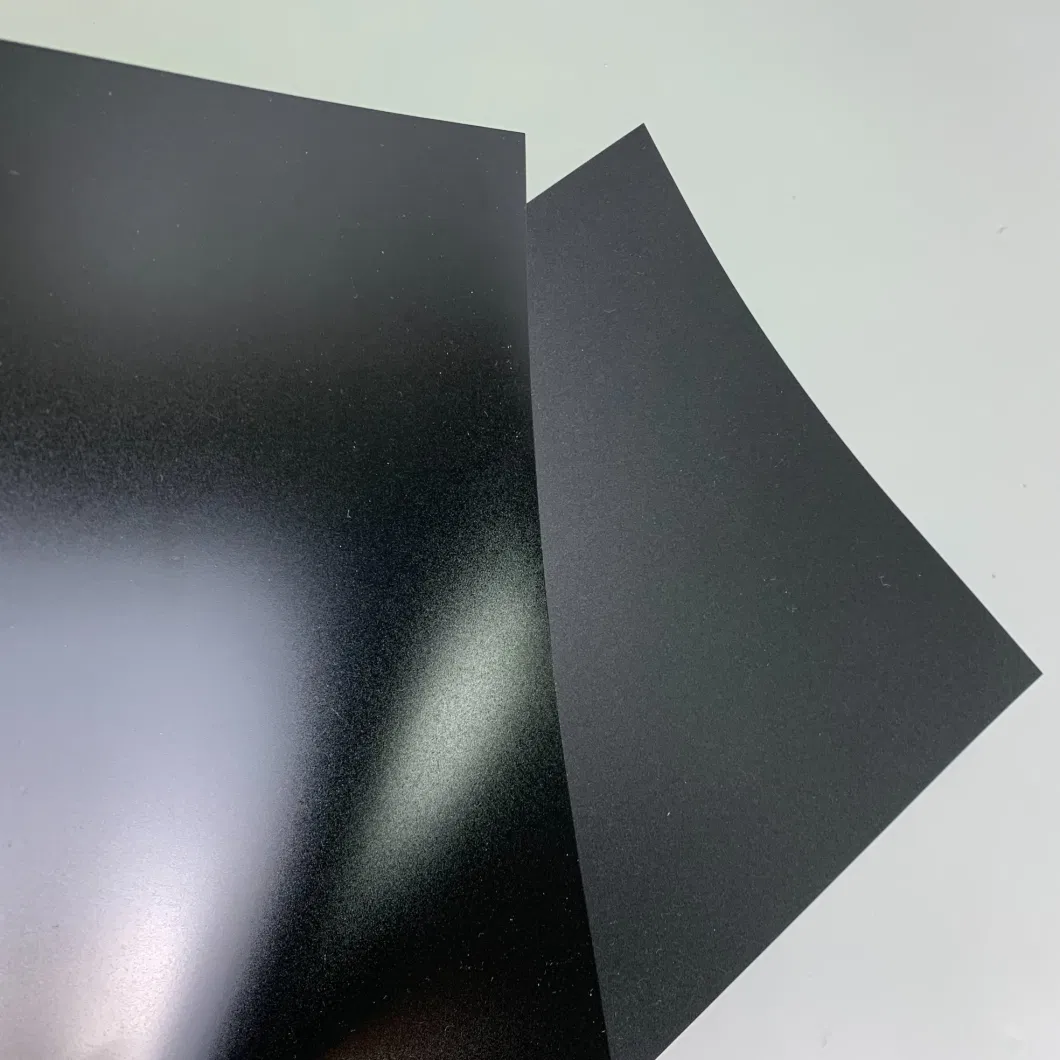

Common color

|

Clear,

|

|

Type

|

Solid,

|

|

Light transmission

|

Up to 88%

|

|

Impact resistance

|

80 times that of glass,15 times that of acrylic sheeting

|

|

Temperature resistance range

|

-40 ~ 120°C

|

|

Light weight

|

Only 1/12 of the weight of glass of the same thickness

|

|

Ultraviolet resistance

|

With UV protective layer

|

|

Flame resistance

|

Rated class HB,V2,V0

|

|

Function

|

Sound and heat proof

|

|

Certification

|

ISO900 ,SGS, ROSH

|

Application:

Automotive industry and electronics, electrical industry, LIQUID crystal display and industrial machinery parts, plating mirror, all kinds of signs, printing, film switch, nameplate, protective mask, can be applied to thick sheet blister machine to do blister processing, making all kinds of PC lampshade, PC marking, protective cover, vending machine panel, lighting cover and so on.

1.Excellent films for multi-layer printing for applications such as overlays, floor graphics, high performance labels and in-mould decoration.

2.Can be screen printed using traditional solvent based or water based inks, as well as UV or infrared drying inks and offer ease of processing for thermoforming, embossing, die-cutting, hydro-forming and bending.

3. Be used over light-emitting devices (LEDs).

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film ,

PET PETG Rigid Film,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products