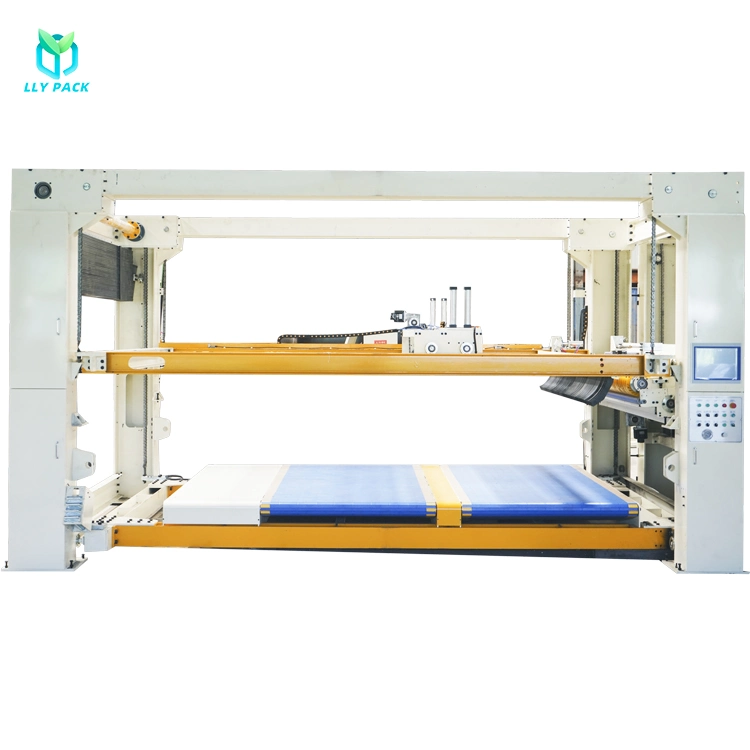

Automatic Stacker

A Complete Corrugating Board Production Line Includes The Following Machines: Mill Roll Stand, Pre-Heater, Splicer, Single Facer, Over Bridge, Multi-Pre-Heater, And Glue

Machine, Double Baker, Slitter Scorer, Cutoff, Stacker, And Ect.

Raw Paper Roll Is Fed To The Roll Stand, After Heated And Moisture Adjusted By The Per-Heater, Raw Paper Will Go To Tne Single Facer, Corrugated By It, And Gluing Together With Another Raw Paper To Become Single Faced Corrugating Paper, Then Conveyed Through The Over Bridge, Re-Heated By Multi-Pre-Heater, After Glued By Glue

Machine, Jointed By The Double Backer, Continuous Corrugating Board Comes Out.

After Slitting And Scoring By Slitter Scorer And Transverse Cutting By Cutoff, Corrugating Board With Different Sizes Are Produced. At Last, These Different Sizes Corrugating Board Will Be Stacked, Calculated And Than Send Out By The Stacker.

Heating Way: Steam Heating.

|

Paper Width(mm)

|

External Dimensions (mm) L*W*H

|

Weight(T)

|

Total Power of Motor(kW)

|

|

1400

|

18500*3800*3500

|

9

|

30

|

|

1600

|

18500*4000*3500

|

10

|

30

|

|

1800

|

18500*4200*3500

|

11

|

35

|

|

2000

|

18500*4400*3500

|

12

|

35

|

|

2200

|

18500*4600*3500

|

13

|

39

|

|

2300

|

18500*4700*3500

|

14

|

39

|

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Corrugated Line,

Single Facer,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt ,

Printer Slotter Die Cutter