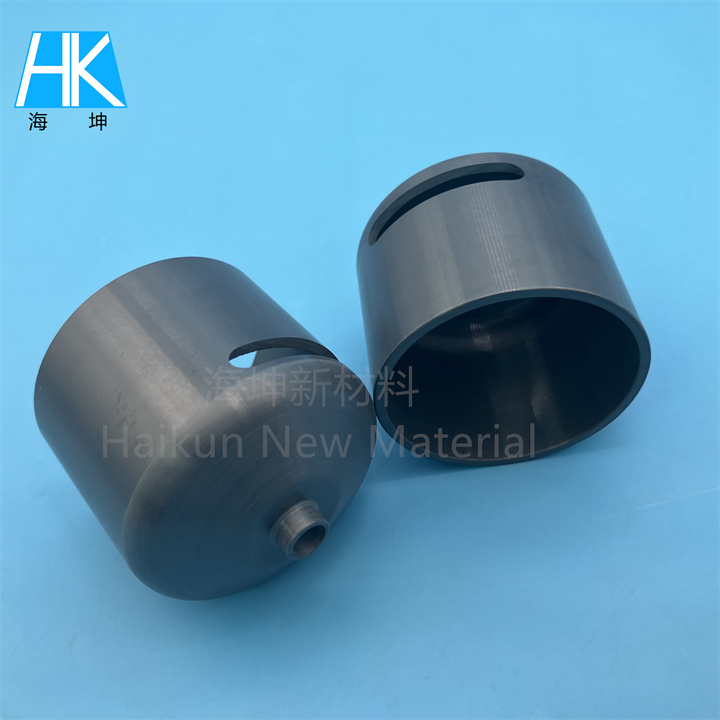

We specialize in providing highly customized grinding silicon nitride ceramic roller washer designed to meet the diverse needs of our customers for Silicon Nitride Ceramic Discs. This custom-made product, made of high quality silicon nitride materials, ensures its excellent mechanical properties and durability through precision manufacturing processes.

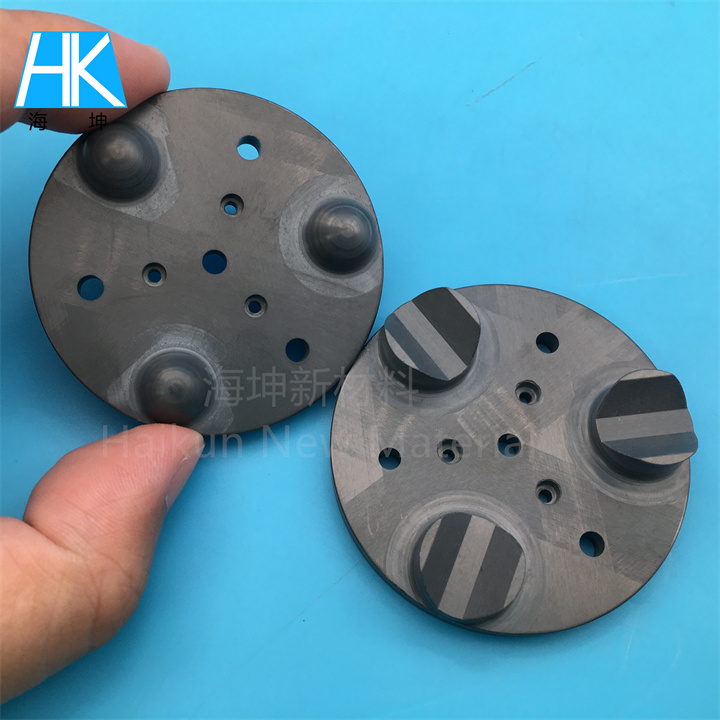

In particular, our Black Silicon Nitride Ceramic Disc, with its distinctive black appearance and outstanding physical properties, has become a notable focus in the market. The Ceramic Structure Disc not only has excellent wear and corrosion resistance, but also maintains excellent stability at high temperatures, making it ideal for high-load, high-precision applications.

In addition, we offer a custom service for the Plate Silicon Nitride Disc, ensuring that every size and shape perfectly matches the customer's equipment needs. From design to production, we follow strict quality control standards to ensure high performance and long-term reliability of our products.

Choose our custom service and you will receive a silicon nitride ceramic roller washer that meets your specific requirements and meets your high demands for performance and reliability.

Products Show

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Alumina Ceramics,

Zirconia Ceramics,

Silicon Nitride Ceramics ,

Macor Ceramic,

Aluminum Nitride Ceramic,

Other Ceramic Materials