Horizontal Continuous Drying Machine

Horizontal Continuous Drying Machine Feature:

1. 1. Horizontal Boiling Drying Machine have Automatic production can be realized. It is continuous drying equipment.

2. 2 Horizontal Continuous Drying Machine are quick in drying speed ,Low in drying temperature ,

3.Horizontal Continuous Dryer have highly polished inner and outer surfaces of the machine, no dead comer, easy to clear, no cross contamination. Confining to the requirement of GMP.

4. 4. It have high collecting rate, high efficiency, fast drying, energy saving.

5. 5. It have not stick onto the wall.

6. Smooth running, reliable performance, easy operation.

7. When oil is used to heat, use automatic constant temperature control. Its temperature of operation can be adjusted form 50-160℃.

8. Horizontal Continuous Drying Machine made by all stainless steel.

9. The feeding system for this machine can be by manual or screw feeder, because the machine is negative pressure drying process, and the feeding materials also can use negative pressure to suck the raw materials into dryer.

10. For the electrical component, we mainly use international brand such as ABB ,Siemens or Schneider.

11. Control system has more choices, such as push button , HMI+PLC and so on.

Horizontal Continuous Drying Machine Application

Horizontal Continuous Drying Machine is also called fluidization bed. Through continuously improvement over 30 years, fluidizing dryer has widely applied in the fields of pharmaceutics, chemicals, foodstuff, processing grain etc. For example, the dehumidification and drying of powder and granular materials such as bulk pharmaceuticals, granular patent medicines, preparations, feed, plastic resin etc. The granular diameter shall be within the range from 0.1 to 6mm and the best from 0.5 to 3mm.

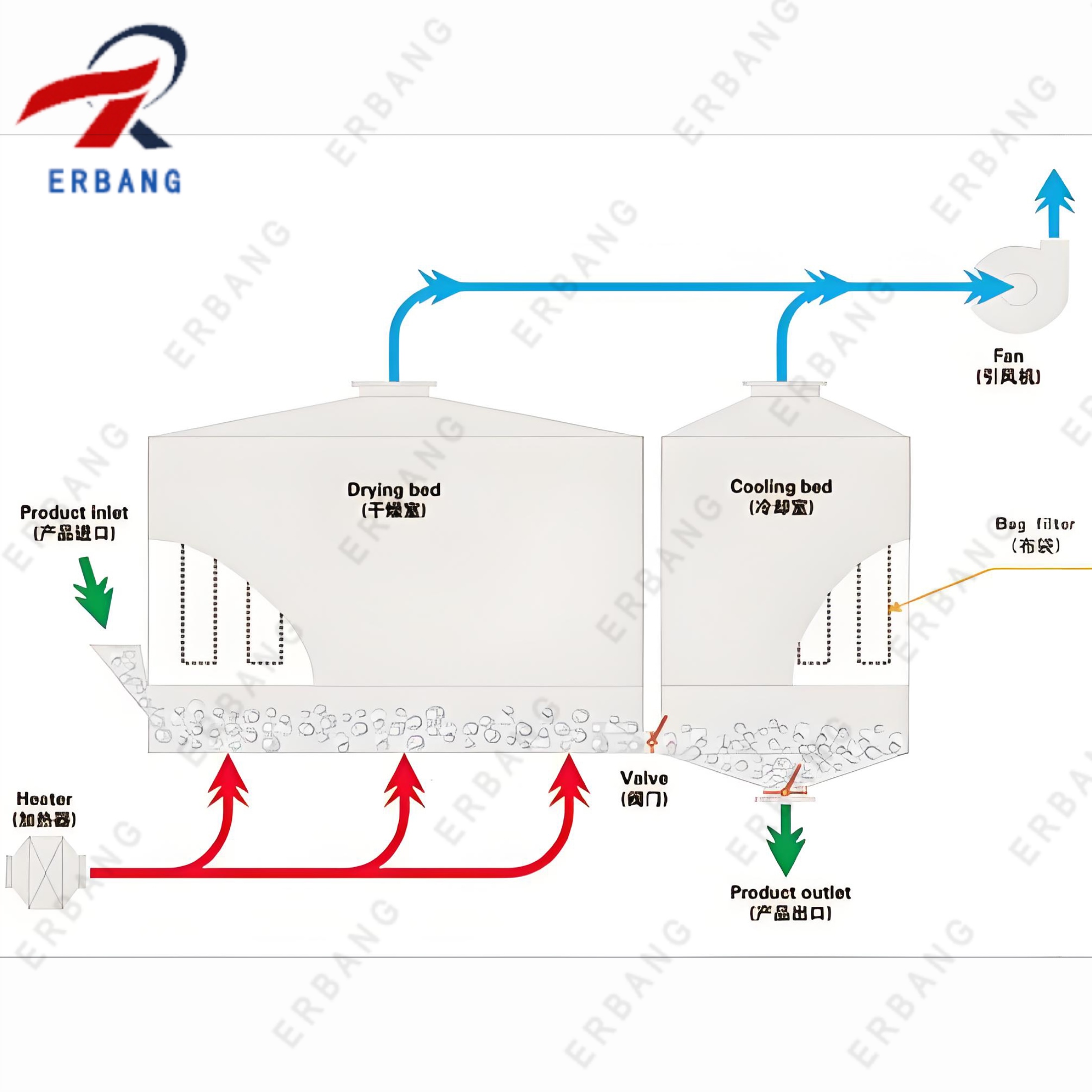

Horizontal Continuous Dryer Principle

The Horizontal Continuous Dryer is heated by means of steam or electric power, and also heated with hot air directly from fuel-& coal-burning hot air furnace.

The main technical parameter datum of fluidizing dryer is for reference. We also produce and design product as per customers' requirement.

| Type | Capacity(water kg/h) | Dimensions(mm) | fan power(kw) | Inlet temp (ºC) | material temp (ºC) | steam(kg/h) | electrical(kw) |

| XF-20 | 20-25 | 2600X800X2800 | 7.5 | 60-140 | 40-80 | 100 | 60 |

| XF-30 | 30-45 | 2600X1000X2800 | 15 | 60-140 | 40-80 | 200 | 120 |

| XF-50 | 50-80 | 5000X1200X3300 | 22 | 60-140 | 40-80 | 400 | 240 |

| XF-80 | 120-150 | 6000X1200X3600 | 45 | 60-140 | 40-80 | 600 | 360 |

| XF-150 | 160-200 | 6000X1200X4200 | 55 | 60-140 | 40-80 | 800 | 480 |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Ternary material reactor,

Drying Machine,

Granulating Machine,

Grinding Machine ,

Mixing Machine,

Coating Machine