Multifunctional Injection Molding Machine for large Plastic Products

1.Overview

We are Ningbo Tiansu Machinery Technology Co., Ltd., a professional maker of high - precision, energy saving plastic injection molding machines. We mainly produce over 20 specs of machines with injection volume from 70g to 10,000g and clamping force from 700KN to 12500KN. As a plastic daily necessities injection machine factory, our large injection molding machine, tailored for large plastic products. From plastic PVC pipes to large plastic trash can, our series of large injection molding machines can be manufactured.

2.Key Features & Advantages

2.1 Multifunctionality: As one of pvc pipe manufacturing machine supplier,this machine ensures precision and consistency across all large plastic products,providing the best injection molding services.

2.2 High Automation: Our custom plastic pvc pipe making machine with advanced automation minimizes human intervention, streamlines processes, boosts efficiency, and cuts errors and downtime.

2.3 Cost-Effective Pricing: Despite its sophisticated design and capabilities, we provide competitive injection molding price. It can ensure long-term savings and profitability.

2.4 Enhanced Safety: This machine injection moulding features multiple safety mechanisms, including emergency stop buttons and protective guards, ensuring a safe work environment for operators.

2.5 High Precision: Every item produced meets industry standards, reflecting the plastic injection machine's capability to handle intricate details tooling plastic and maintain consistency across batches.

2.6 Energy Efficiency: With energy-saving technology at its core, our plastic molding machine minimizes electrical consumption. This contributes to reduced operational costs.

2.7 High Efficiency & Longevity: Our durable molding machine for plastic has a long life and high efficiency, ensuring stable output and fewer repairs.

2.8 User-Friendly Operation: The intuitive panel and interface make the machine easy to operate, reducing training time and enabling quick setting adjustments.

2.9 High Rigidity & Low Noise: The injection machine's rigid frame ensures stability, reduces vibrations, enhances quality, and operates quietly.

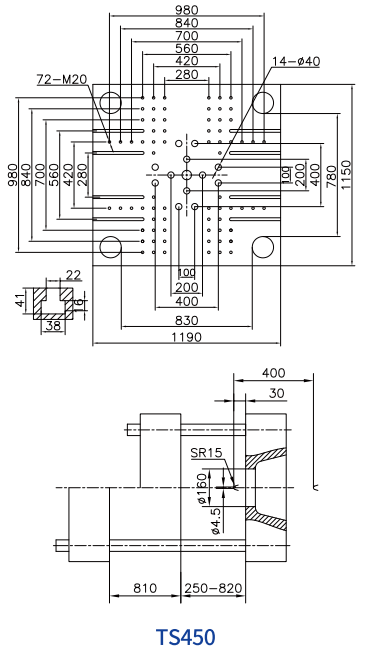

2.10 Wide Tie-Bar Spacing & High Clamping Force: Designed with a large tie-bar spacing, the machine can accommodate molds of various sizes. The high clamping force ensures secure mold closure, preventing leaks and ensuring precise product replication. Suitable for many pvc mold.

The injection part resulting from this process can be found in various industries, including aerospace, medical, and electronics. Additionally, molded metal parts are becoming increasingly popular due to their strength, durability, and design flexibility.Beyond plastics and metals, molding ceramic materials has also gained traction in recent years, offering a new medium for artists and manufacturers to explore. However, the true heart of the injection molding industry lies in the expertise and capabilities of molding companies. These businesses, like molding companies near me, specialize in providing custom solutions for a wide range of molding needs.

The process of molding over molding allows manufacturers to create multi-material parts in a single operation, enhancing both functionality and aesthetics. Meanwhile, injection machines and molds for plastic are constantly evolving, incorporating advanced technology to improve efficiency and reduce waste.One such advancement is extrusion moulding, a process that extrudes heated plastic through a die to form continuous shapes, such as pipes and tubing. For pvc mold and other types of molds, finding a reputable mold manufacturer or mold manufacturing service is crucial to ensuring quality and precision.

Our hydraulic systems are top notch. The injection molding machine hydraulic motor and powerful hydraulic drive for molding, along with energy efficient hydraulic pumps like variable displacement pump, are integral to our machines. We also offer injection molding machine hydraulic pumps for plastics industry.In addition to the main machines, we provide a wide array of injection molding accessories and auxiliary equipment. From injection molding cooling devices, material handling machines for injection molding to electric drives such as injection molding electric motors for reliable electric injection molding machines. Our high quality conveyor belts, including injection molding machine conveyor belts and plastic product conveyor belts, ensure smooth production. We also have advanced mold temperature control solutions like air cooled water chillers, industrial water cooling machines, and advanced mold heating and control machines.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Injection molding machine,

Auxiliary machine,

injection machine Nozzle,

Drive Belt and Pulley ,

injection machine Electric Motor,

injection Molds