Guosheng Intelligent Technology Machine Tool Co., Ltd. is a collection of machine tool production and sales, machine tool accessories and accessories sales, machine tool maintenance and transformation as one of the integrated company. The company has its own brand of CNC lathes, machining centers, sawing machines, drilling machines, grinding machines, metal forming machine tools, special machine customization and other full series of machine tool products, serving the machining industry for many years, has a strong after-sales service team, not only for their own product after-sales service, but also undertake various machine tool maintenance, service in place in time.

Equipment overview

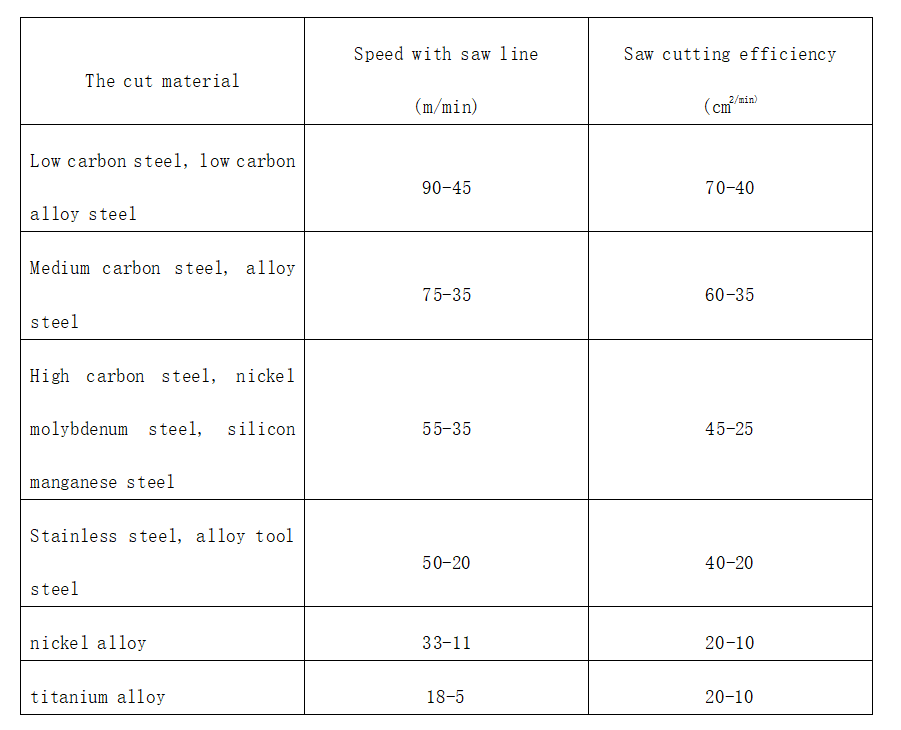

This series of machine tools is mainly used for small and medium size bar and pipe materials and profiles sawing, and can adapt to all kinds of black metal materials sawing processing. It has the characteristics of high cutting efficiency, energy saving, narrow saw edge, energy saving and simple operation.

The machine consists of the following main parts

1. Base

2. Main transmission system

3, clamping device

4. Saw frame

5. Guide device

6. Left and right columns

7, saw blade tension device

8. Cooling system

9. Hydraulic system

10. Electrical system

Function description of each part

1, base: base is welded with high-quality steel plate, after vibration aging treatment, welding deformation is small, mainly used to install the various parts of the machine tool, the left and right sides of the bed are installed left and right columns and lifting cylinders and clamping vise, while the right end of the bed is a water tank for cooling during the sawing process.

2, the main transmission: the main transmission system of the machine tool is composed of the reducer, the driving wheel, etc., the reducer and the driving wheel are directly connected, the transmission is smooth and there is no impact. The speed of the driving wheel is adjusted by the frequency converter, and a variety of cutting speeds can be obtained to meet the sawing of different materials.

3, clamping device: the clamping of the machine tool with hydraulic vise clamping, in the saw belt behind the design of a set of hydraulic vise, the cylinder using screw thread structure cylinder. When clamping, the button on the panel is operated, and the clamp plate is driven by the hydraulic cylinder to clamp the workpiece.

4, saw frame: saw frame is a bow structure, divided into left, right saw frame, beam, saw frame plate using high-quality steel plate, through a reasonable reinforcement of welding, vibration aging will be redistributed and eliminated welding stress, so as to ensure the stability of the saw frame. The driving wheel, tension wheel and left and right guide device are installed on the saw frame, and the saw wheel turns counterclockwise when the machine is working.

5, guide device: the guide of the machine is divided into active guide arm and fixed guide arm, the movement of the active guide arm is manually moved. After adjustment, the locking of the guide arm is manually locked by dovetail device. The top of the guide seat is made of high-quality bearings, the side is made of cemented carbide, and the pre-guide device is provided to ensure the stability of the guide and extend the service life of the saw blade. Guide dovetail is equipped with a fast-forward bar to shorten the customer sawing waiting time.

6, column device: In order to increase the stability of the machine tool, the machine tool adopts double column square column structure, the lifting of the saw frame is driven by the cylinder, the bottom of the cylinder is hinged, to avoid over-positioning, affecting the stability of the saw frame lifting.

7. Saw blade tensioning device: The tensioning wheel is installed on the left end of the saw frame. After the band saw blade is loaded into the driving wheel and the tensioning wheel, the saw belt is tensioned or loosened by hydraulic tensioning.

8. Cooling system and scavenging device: In order to extend the service life of the saw blade, prevent the saw blade from heating and ensure the sawing accuracy, the machine adopts a cooling pump for centralized cooling, and the cooling point is divided into the left and right guiding arm position. The coolant is recycled and the coolant is saponified. Install a chip wheel to clean the saw belt of residual sawdust.

9, hydraulic system Hydraulic system is mainly composed of 1 oil tank, 1 hydraulic motor, 1 oil pump, multiple solenoid valves and so on.

10, electrical control system This machine tool is designed a separate electrical control cabinet, all electrical components are installed in the electrical cabinet, in order to ensure safety, each action is interlocked. Specifically: the vise is not clamped, the main drive can not work; The vise must not be loosened during the sawing process.