Reason:

1. The furnace temperature is too high or too low

2. Curing time is too long or too short

3. Insufficient exhaust of curing furnace

Solution

1. Adjust the furnace temperature of the curing furnace

2. Adjust the chain speed

3. Check the exhaust system or increase the exhaust air hole

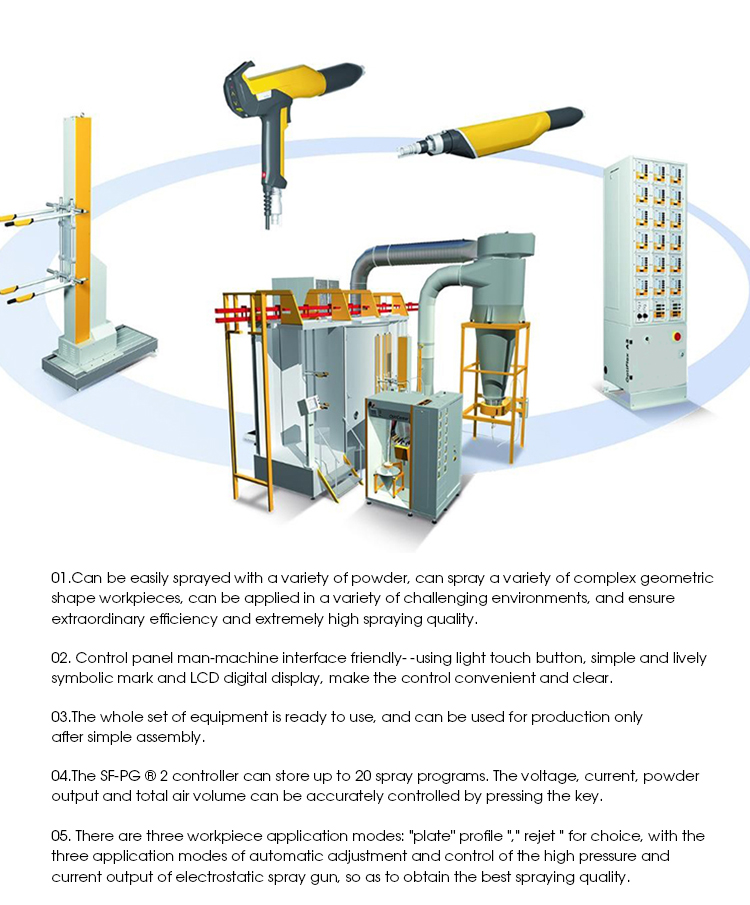

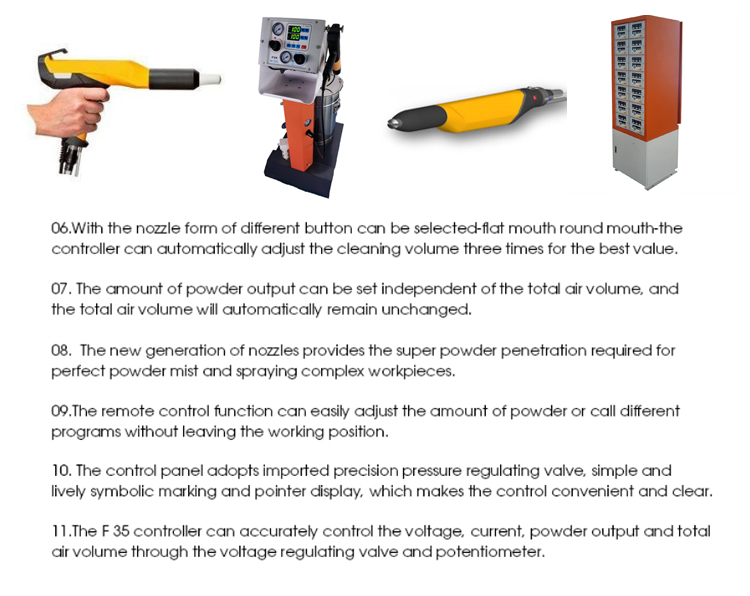

1. The powder coating booth is made of anti-static imported engineering plastic ,the structure is like a sandwich ,so that it can ensure a higher powder yield, the smallest powder retentate, the fastest speed of cleaning.

2. The rate of the cyclone special separation technology is up to 98% once ,so that it can save powder. Solve the problem of powder on the dead angle of the workpiece thoroughly.

3. The bottom of the powder coating booth is equipped with automatic turning-over device or automatic cleaning air knife, the bottom floor of the spray room is almost no powder retentate.

4. The powder supply center achieves the automatic circulation of the powder thoroughly. The powder supply center will automatically clean the powder suction pipe, powder pump ,powder carried pipes and spray gun When cleaning the powder coating booth.

5. New automatic powder adding device can be configured additionally.

6. Can be equipped additionally with automatic cleaning device for spray gun and a complete body of gun.

7.Using High-quality nano-coated filter,it can capture the powder above 0.1 micron.The gas can be discharged/circulated directly in the room after filtered.

8. The powder supply center adopts the design of saving powder , to reduce the fluidized coating powder to the minimum.

9. The functionalized man-machine interface is with the touch-screen

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

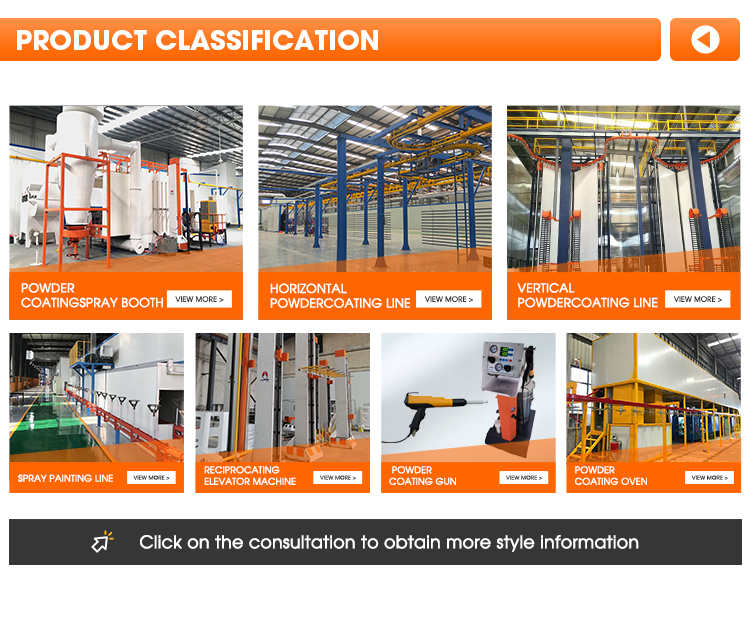

Main Product:

powder coating machine,

powder coating booth,

powder coating line ,

powder coating gun,

powder spray machine,

powder coating oven