Super strong block neodymium magnet customized shape and size available

|

Material |

Neodymium Magnets |

|

Grade |

N35-N52, 33M-50M, 30H-48H, 30SH-45SH, 30UH-40UH, 28EH-38EH, 30AH-33AH |

|

Demension |

Customized size |

|

Coating |

Silver, Gold, Zinc, Ni-cu-Ni. Epoxy etc. |

|

Shape |

Customized NdfeB magnet shape |

|

Magnetization direction |

Thickness, Length, Axially, Diametre, Radially, Multipolar |

|

Application |

NdfeB Neodymium rare earth permanent magnets are widely applied in Auto, energy-efficient Motors and Generators, Machinery, Audio/Video and Communication Equipment, Medical Device(MRI), Office Automation, Magnetic Separator, etc. |

|

Delivery time |

15-30 days according to order quantity |

|

Capicity |

5000 tons each year |

|

Packaging |

35x28x20cm or as per your request |

product parameters as follow

Magnetic Direction As Follow

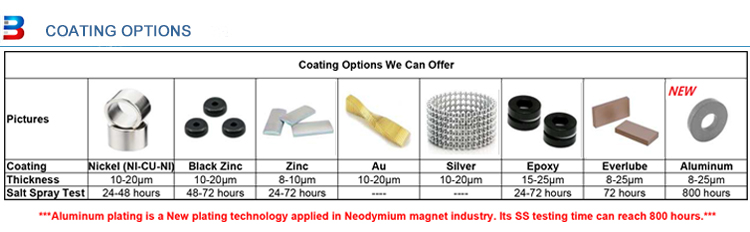

Coating Options We Can Offer

NOTE :Aluminum plating is a new plating technology applied in Neodymium magnet industry ,Its SS testing time can reach 800 hours

Product Application

--Widely Used In Many Fields

BESTEN MAGNET is a high-tech company specialized in permanent magnet research and development in China. The factory was established in 1999, as one of the leading sintered NdFeB magnet manufacturers, the company has an annual capacity of 5,000 tons. With years of innovation and efforts, testified by numerous technical inventions, focusing on the customer’s magnetic requirements and needs, the company laid a success story for decades by processing highest quality of permanent magnets for a growing number of customers in Europe, Asia and North & South American and other markets. We supply comprehensive and professional permanent magnets and related magnetic products. Our magnet products are widely applied in Auto, energy-efficient Motors and Generators, Machinery, Audio/Video and Communication Equipment, Medical Device(MRI), Office Automation, Magnetic Separator, etc.

Production Procedure

it will need 13 stpes from material to the customized produce as follow ,Material Verifcation ,smelting ,H.D,Jet Milling ,Powder Mixture ,Moulding ,Sintering ,Characteristic testing ,Machining ,Plating ,Magnetizing ,Packing and Deliverly .

Besten Magnet is comding our customers with defect-free products in timely fashion at the lowest price. We make a considerable investment in advanced pieces of instrumentation to measure and observe magnetic property, accurate dimension and plating thicknesses of our products. These devices ensure Besten products precisely meets the original design requirements.

packaging : Sea Pallet /Air Carton /Express Packing /Plastic Tube /Wooden Case and as Customized package

Q1. How long would I get your feedback?

A: We will reply your questions or inquiry within 24 hours and we service 7 days per week.

Q2. Can you supply custom magnets?

A: Sure, we offer customized magnets. Virtually any shape of Neodymium magnet can be made to your requirements and design.

Q3. Can you add my logo on your products and do you offer OEM or ODM service?

A: Sure, we can add your logo on the products as your requirements and OEM & ODM service are warmly welcome!

Q4. What package do you use for the products?

A: We have export standard foam-filled cartons. Besides we also offer tailored packaging per customer request. Our packages appropriate to both air and sea shipment available.

Q5. What’s the transportation method of Neodymium magnet?

A: All shipping methods on offer: courier (TNT, DHL, FedEx, UPS), air or sea, with transit tracking regardless. Shipper or freight forwarder may be appointed by either purchaser or Besten magnet.

Q6. Do you provide samples?

A: Sure, we offer samples for free if we have magnet in stock.

Q7. How do you control your quality?

A:We have been monitoring from raw materials to the whole production processes and uses various advanced testing instruments to ensure the quality stability before the raw material is put in storage. Our QC Department ensures an ongoing development and maintenance of high quality standards by strictly complying with our Quality Management System as well as all applicable regulations and customer requirements for all finished products. Automatic Production lines were put into operation to raise reliability of products Performance to improve production efficiency.

Q8. What are Neodymium magnets?

A: Neodymium magnets are a member of the rare earth magnet family. They are also called "rare earth magnets" because neodymium is a member of the "rare earth" elements on the periodic table. Neodymium magnets are the strongest of the rare earth magnets and are the strongest permanent magnets in the world.

Q9. What's the Grade of a magnet ?

A: Neodymium Permanent Magnet are graded according to their maximum energy product of the material that the magnet is made from. It relates to the magnetic flux output per unit volume. Higher values indicate stronger magnets and range from N35 up to N52. and M, H, SH, UH, EH, AH series, can be customized into a wide range of shapes and sizes with precise tolerances. Multiple choices of coatings and magnetization orientations can meet specific customer requirements. Letters following the grade indicate maximum working temperatures (often the Curie temperature), which range from M (up to 100 °C) to EH (200 °C) to AH (230 °C)

Q10. What’s the working temperature for various grades of Neodymium magnets?

A: Neodymium Iron Boron magnets are sensitive to heat. If a magnet heated above its maximum operating temperature, the magnet will permanently lose a fraction of its magnetic strength. If they are heated above their Curie temperature, they will lose all of their magnetic properties. Different grades of neodymium magnets have different maximum operating temperatures.

Q11. What is the difference between the different plating?

A: Choosing different plating does not affect the magnetic strength or performance of the magnet, except for our Plastic and Rubber Coated Magnets. The preferred coating is dictated by preference or intended application. More detailed specifications can be found on our Specs page.

• Nickel is the most common choice for plating neodymium magnets. It is actually a triple plating of nickel-copper-nickel. It has a shiny silver finish and has good resistance to corrosion in many applications. It is not waterproof.

• Black nickel has a shiny appearance in a charcoal or gunmetal color. A black dye is added to the final nickel plating process of the triple plating of nickel-copper-black nickel. NOTE: It does not appear completely black like epoxy coatings. It is also still shiny, much like plain nickel plated magnets.

• Zinc has a dull gray/bluish finish, that is more susceptible to corrosion than nickel. Zinc can leave a black residue on hands and other items.

• Epoxy is basically a plastic coating that is more corrosion resistant as long as the coating is intact. It is easily scratched. From our experience, it is the least durable of the available coatings.

• Gold plating is applied over the top of standard nickel plating. Gold plated magnets have the same characteristics as nickel plated ones, but with a gold finish.

• Aluminum plating is a New plating technology applied in Neodymium magnet industry. It’s a kind of protection film with fine integral performance, smoother that mechanical galvanizing layer, without porosity, with high impact resistance and it’s corrosion resistance was better than any of other plating layers. Its SS testing time can reach 800 hours.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Arc Sintered NdFeB Magnets,

Sintered NdFeB Magnets,

Bonded NdFeB Magnets,

AlNiCo Magnets,

SmCo Magnets ,

Magnetic Assembly