Product description and features of manual flat plate valve:

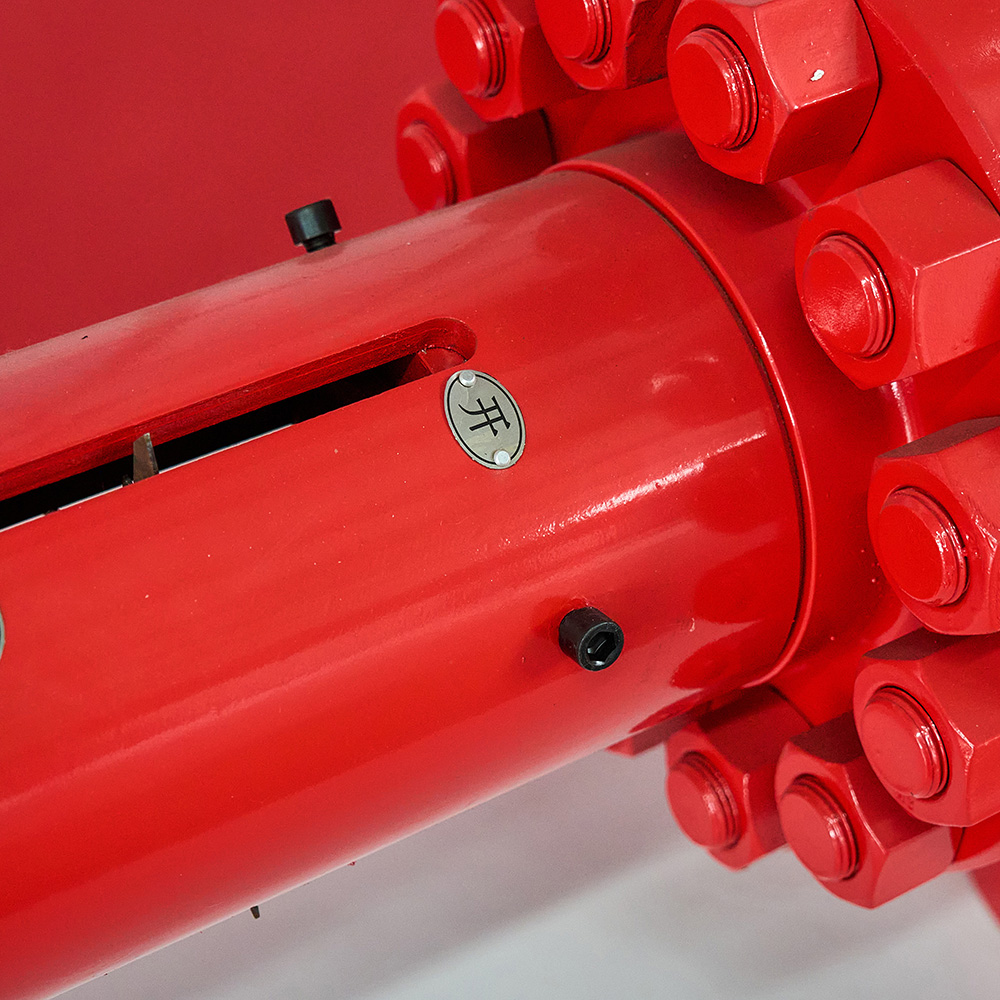

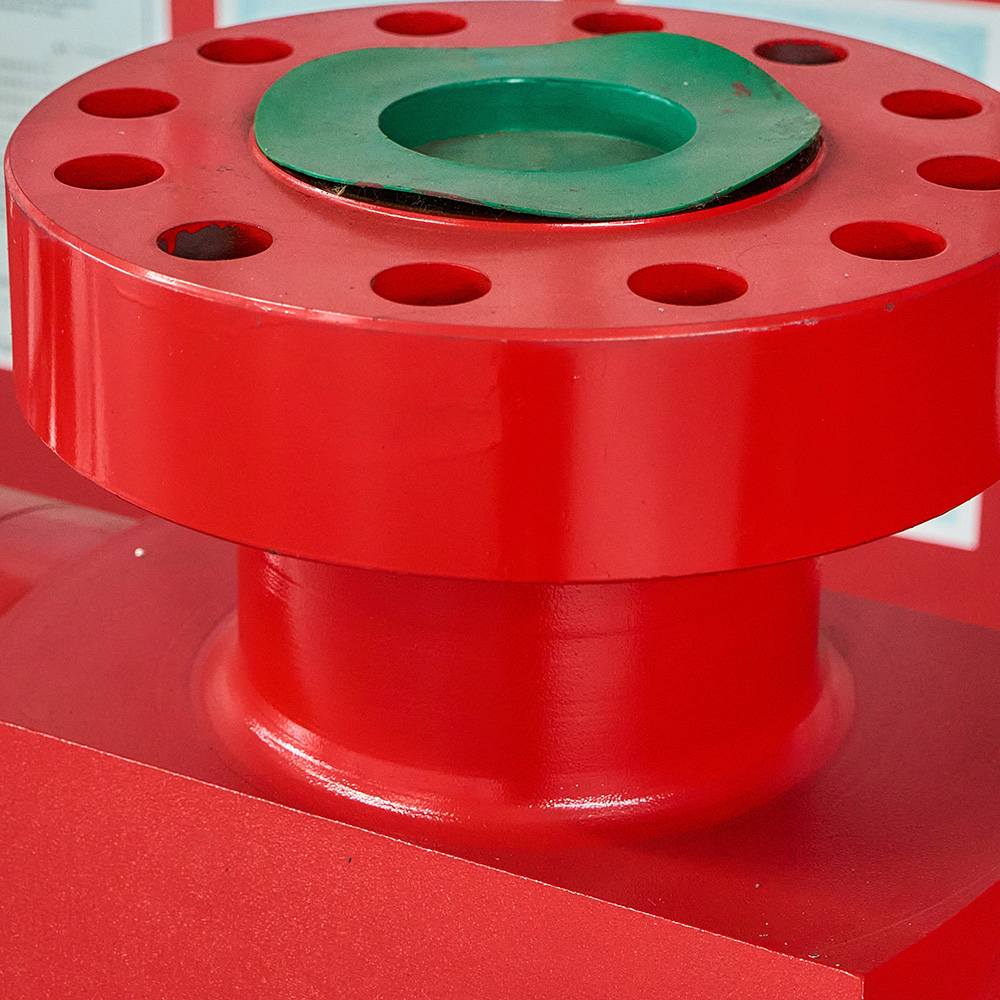

Structural design: The manual flat plate valve is mainly composed of valve body, valve seat, gate, valve stem, handwheel and other components. The valve body is usually manufactured by casting or welding process, with good pressure resistance and sealing. The sealing surface of the valve seat and the gate is finely processed and specially treated to ensure a good sealing effect. The valve stem is connected to the gate, and the valve stem is driven up and down by rotating the handwheel to realize the opening and closing control of the gate.

Working principle: The manual flat plate valve is a cut-off valve. Its gate is parallel to the fluid channel when opened and perpendicular to the channel when closed. The fluid is controlled by the lifting and lowering of the gate. When the handwheel is rotated clockwise, the valve stem drives the gate down, and the gate fits tightly with the valve seat to cut off the fluid channel; when the handwheel is rotated counterclockwise, the gate rises, the fluid channel opens, and the medium can pass smoothly.

Scope of application: widely used in petroleum, natural gas, chemical, metallurgy, mining, electricity, building materials, light industry, grain and other industries, suitable for water, oil, natural gas, coal gas, dust materials, pulp, coal ash, chemical raw materials, sewage, food and other media pipelines, venting systems and storage devices, used as opening and closing equipment

Product Parameters:

| Product name |

valve |

| Specification model |

5 1/8 |

| Implementation standard |

API 6A |

| Rated working pressure |

15000PSi |

| Product specification level |

PSL1~PSL3G |

| Product performance level |

PR1~PR2 |

| Temperature level |

PU, LU |

| Material level |

AA~FF |

| Product color |

red |

Advantages:Low flow resistance: The medium channel inside the valve body is straight, and the medium flows in a straight line. When fully open, the channel is smooth and straight, the flow resistance coefficient is extremely small, there is no pressure loss, and the pipeline can be cleaned by hair balls.Opening and closing is more labor-saving: Compared with the stop valve, the movement direction of the gate is perpendicular to the flow direction of the medium, and the floating valve seat and other structures are adopted. The opening and closing torque is only 1/2 of that of the ordinary valve, which can easily open and close the valve.Reliable sealing: The sealing structure of the valve seat should be elastic with pre-tightening force, and the upstream and downstream sealing seats should be sealed at the same time. The valve seat and the seal are always face-to-face sealed. Some flat plate valves use metal-to-metal seals and are equipped with a grease injection structure to achieve zero leakage.Compact structure: simple shape, short structure length, good manufacturing processability, small space occupation, suitable for various installation environments.Flexible operation: When operated manually, the handwheel rotates lightly, and the valve can be opened or closed at any time as needed. During the closing process, the movement of the gate and the valve seat is smooth and not prone to jamming.Long life: The valve seat has a self-cleaning function and is not directly eroded by the airflow during the opening or closing of the valve. At the same time, the gate and the valve seat are treated with special processes and spray-welded with wear-resistant materials such as hard alloys to extend their service life.Easy maintenance: The failure of the valve actuator will not affect other parts of the valve, and maintenance and replacement work can be carried out without removing the valve. And some parts adopt an assembled structure, which is easy to disassemble and install.Disadvantages:The sealing surface is easy to wear: When opening and closing, the two sealing surfaces of the gate and the valve seat rub and slide against each other, which are prone to abrasion and wear under the action of the medium pressure, affecting the sealing performance and shortening the service life.Large height, long opening and closing time: The gate has a large opening and closing stroke, and is usually lifted and lowered by a screw, so the time required to open and close the valve is relatively long.Expensive price: Due to the large number of contact sealing surfaces, the processing is more complicated, especially the sealing surface on the gate seat is not easy to process, and there are many parts, resulting in a high manufacturing cost for the manual flat valve and a relatively expensive price.

As a petroleum machinery manufacturer, our company also produces Blowout Preventer, Manifold, Cellar Connection, Valve, Pipe Fitting and Control Apparatus, etc.

If you need, please contact us.

Detail Pictures:

Our Service: