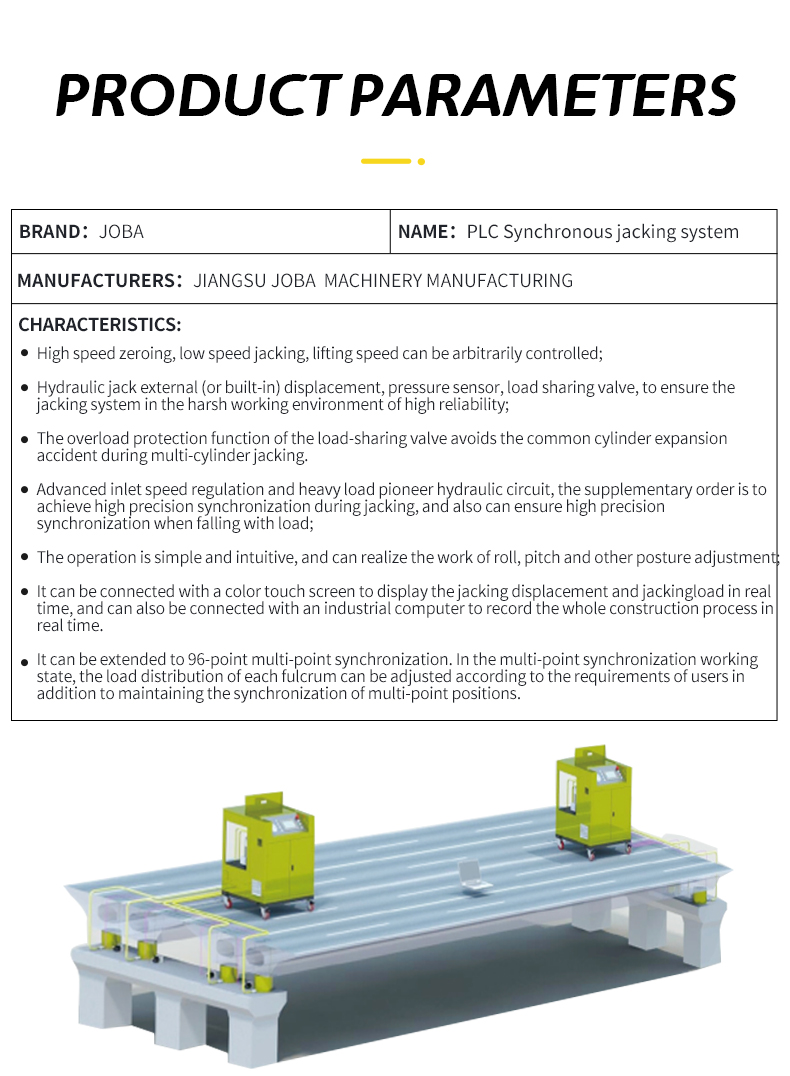

The function of the Plc Synchronous Jacking System is to control and monitor the operation of multiple jacking devices so that they can coordinate their movements at the same time to achieve smooth and efficient jacking operations. Specific functions include:

1. Synchronized control: Synchronized Hydraulic Jacking Systems can control the movement of multiple jacking devices through programming to ensure that they can perform lifting operations in a predetermined sequence and speed. This can avoid incoordination and conflicts between jacking devices and improve the efficiency and safety of jacking operations.

2. Load balancing: Synchronous Jacking System can achieve load balancing among multiple jacking devices. The system can automatically adjust the movement speed and strength of each lifting device according to the load of the lifting device to ensure that the load borne by each lifting device is relatively balanced and to avoid damage to the lifting device or unstable work due to uneven loads. .

3. Fault monitoring: Synchronous Jacking System can monitor the operating status of the jacking device in real time, including motor current, sensor signals, etc., and perform fault detection and alarm through programming logic. Once an abnormality or failure in the jacking device is found, the system can stop operation in time and provide corresponding fault information to facilitate maintenance and repair by maintenance personnel.

4. Data recording and analysis: The PLC synchronous jacking system can record and store the operating data of the jacking device, including lifting time, speed, load and other information. These data can be used for subsequent analysis and optimization to help improve the efficiency and reliability of the jacking device and reduce energy consumption and maintenance costs.

In short, the PLC synchronous jacking system can realize the coordinated movement of multiple jacking devices to ensure that they complete the jacking operation efficiently and safely, and provides fault monitoring and data analysis functions to improve the reliability and work efficiency of the jacking system.

|

Features of PLC Synchronous Jacking System

|

|

|

|

1

|

Displacement precision ≤±0.2mm.

|

|

|

2

|

Working voltage: AC380V/50Hz(Three-phase-Five-wire system).

|

|

|

3

|

Control voltage: DC24V.

|

|

|

4

|

Control pattern: frequency conversion speed regulating.

|

|

|

5

|

Pressure sensor: input DC24V, range: 0-70MPa,output: 4-20mA.

|

|

|

6

|

Displacement sensor: input24V, range: 0-1000mm, Push-pull.

|

|

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Hydraulic Jack ,

Hydraulic Wrench,

Hydraulic Pump,

Bearing Heater,

Hydraulic Puller,

Hydraulic Hole Punching Tool