High precision vortex street flowmeter is an instrument based on the Karman vortex principle, used for precise measurement of fluid flow rate. Here is the relevant introduction:

1. Characteristics

① High accuracy: generally up to ± 1% r or ± 0.5% r, it is almost unaffected by fluid density, pressure, temperature, viscosity and other parameters when measuring volumetric flow rate under various working conditions, and can adapt to fluid flow measurement under various working conditions.

② Strong stability: adopting integrated design, compact structure, strong anti-interference ability, can maintain stable working state in harsh environments.

③ Wide range: The range ratio can generally reach 10:1 to 100:1.

④ Small pressure loss: Its design reduces the pressure loss generated during the measurement process, which helps to reduce system operating costs and has energy-saving significance.

⑤ Easy maintenance: The structure is simple, there are no movable mechanical parts, the sensor does not directly contact the measured medium, the reliability is high, and the maintenance amount is small.

⑥ There are various signal outputs, including analog standard signals and digital pulse signals, which are easy to use in conjunction with digital systems such as computers, facilitating automation control and remote monitoring.

2. Working principle: A triangular cylindrical vortex generator is set up in the fluid. When the fluid passes through, regular vortices, known as Karman vortices, are alternately generated on both sides of the vortex generator. The release frequency of vortices is related to the average velocity of the fluid flowing through the vortex generator and the characteristic width of the vortex generator. By measuring the vortex frequency, the average velocity of the fluid flowing through the vortex generator can be calculated, and then the flow rate can be determined.

3. Installation requirements

① Requirements for straight pipe section: To ensure measurement accuracy, it is generally necessary to ensure the length of the straight pipe section from the first 40D to the last 20D (where D is the diameter of the pipeline).

② Avoiding interference sources: Strong electrical equipment, high-frequency equipment, strong power switch equipment, high-temperature heat sources, radiation sources, strong vibration areas, and strong corrosive environments should be avoided.

③ Installation method: There are horizontal and vertical installation methods. When measuring gas flow, if the measured gas contains a small amount of liquid, the sensor should be installed at a higher position in the pipeline; When measuring liquid flow rate, if the measured liquid contains a small amount of gas, the sensor should be installed at a lower position in the pipeline.

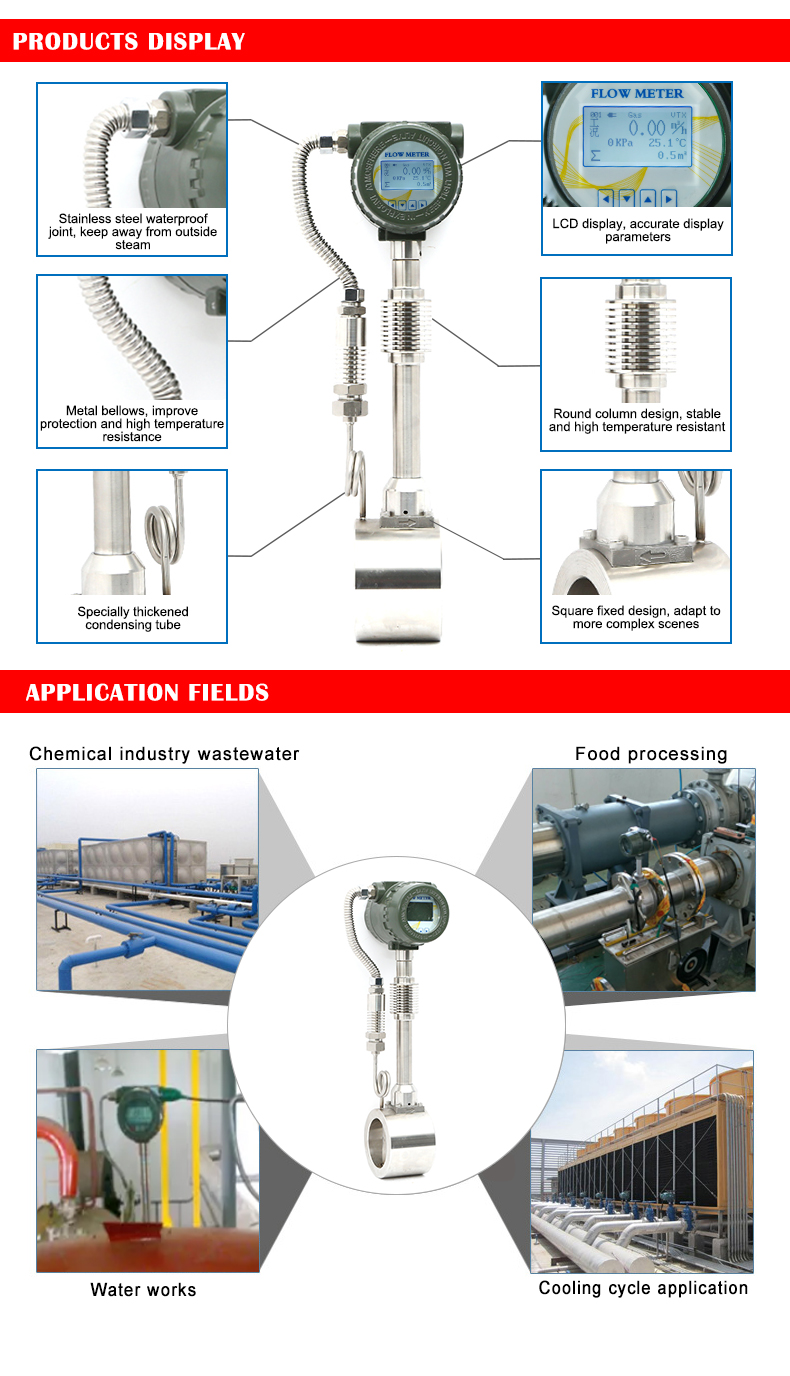

① Industrial production: Used to measure the flow rate of various liquids and gases in the production processes of industries such as petroleum, chemical, metallurgy, and power.

② Municipal construction: It is widely used in the fields of water supply and drainage, sewage treatment, air conditioning, HVAC, etc., to ensure the normal operation of urban infrastructure.

③ Environmental monitoring: can be used for monitoring pollution source discharge outlets, real-time monitoring of pollutant emissions, and providing data support for environmental protection departments.

④ Laboratory research: Used as experimental equipment for studying topics such as fluid mechanics and heat transfer in research institutes and university laboratories.

We specialize in producing electromagnetic flowmeter, vortex street flowmeter, turbine flowmeter, thermal gas mass flowmeter, metal tube rotameter, orifice flowlmeter, ultrasonic flowmeter, verabar flowmeter, target type flowmeter, magnetic level indicator, differential pressure transmitter, etc.