Trigonox® BPIC-C75 Product Description

styrene polymerization copolymerization initiator UP resin initiator

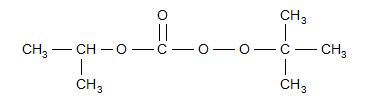

Trigonox BPIC-C75, full name tert-butylperoxyisopropyl carbonate, is an aliphatic percarbonate used for curing unsaturated polyester resins at high temperatures. Specially designed for curing UP resin-based hot pressing formulations (SMC, DMC, BMC, etc.) in the temperature range of 120-170 °C.

Trigonox BPIC-C75 is a recognized faster and more efficient hydrogen peroxide compared to Trigonox C, tert-butyl peroxybenzoate. This means faster, better curing with lower residual styrene content in the molded part. Combined with the optimum low profile or low shrinkage formulation, a very smooth and regular molded product surface can be achieved.

|

|

Molecular weight Active oxygen content peroxide |

: 176.2 : 9.08% |

|

|

CAS No. |

: 2372-21-6 |

|

|

EINECS/ELINCS No. |

: 219-143-7 |

|

|

TSCA status |

: listed on inventory |

|

Specifications |

Appearance Color |

: Clear liquid : 10 Pt-Co max. |

|

|

Assay |

: 74.0-76.0% |

|

|

Active oxygen |

: 6.72-6.90% |

|

|

Hydroperoxides as TBHP |

: 0.10% max. |

|

|

Inorganic + organic hydrolysable chloride |

: 150 mg/kg max. |

|

Characteristics |

Density, 20°C Viscosity, 20°C |

: 0.900 g/cm3 : 2.3 mPa.s |

Storage Due to the relatively unstable nature of organic peroxides a loss of quality can be detected over a period of time. To minimize the loss of quality, recommends a maximum storage temperature (Ts max.) for each organic peroxide product.

For Trigonox BPIC-C75 Ts max.= 25°C and

Ts min. = -20°C to prevent crystallization

When stored according to these recommended storage conditions, Trigonox BPIC-C75 will remain within the AkzoNobel specifications for a period of at least 3 months after delivery.

Thermal stability Organic peroxides are thermally unstable substances, which may undergo self-accelerating decomposition. The lowest temperature at which self- accelerating decomposition of a substance in the original packaging may occur is the Self-Accelerating Decomposition Temperature (SADT). The SADT is determined on the basis of the Heat Accumulation Storage Test.

Trigonox® BPIC-C75 Major decomposition products

Carbon dioxide, Methane, Acetone, tert-Butanol, Isopropanol

Packaging and transport

In North America Trigonox BPIC-C75 is packed in non-returnable, one gallon polyethylene containers of 7 lb net weight (4 per case) and in 5 gallon containers of 35 lb net weight.

In other regions the standard packaging is a 30 l HDPE can (Nourytainer®) for 25 kg peroxide solution.

Both packaging and transport meet the international regulations. For the availability of other packed quantities consult your AkzoNobel representative.

Trigonox BPIC-C75 is classified as Organic peroxide type C; liquid, Division 5.2; UN 3103; PG I

Safety and handling Keep containers tightly closed. Store and handle Trigonox BPIC-C75 in a dry well-ventilated place away from sources of heat or ignition and direct sunlight. Never weigh out in the storage room.

Avoid contact with reducing agents (e.g. amines), acids, alkalis and heavy metal compounds (e.g. accelerators, driers and metal soaps).

The decomposition products of Trigonox BPIC-C75 are low volatile compounds, which makes the peroxide very suitable for the production of e.g. microwave cookware.

For a further increase of the reactivity, Trigonox BPIC-C75 can be used in combination with a high reactive peroxide like Trigonox 21 or Trigonox 141.

Dosage Depending on application and working conditions, the following peroxide dosage level is recommended:

Trigonox BPIC-C75 1 - 2 phr *

Cure Characteristics in pure UP resin:In a high reactive standard orthophthalic UP resin the following application characteristics were determined:

1 phr Trigonox BPIC-C75 80°C

1 phr Trigonox C 80°C

1 phr Trigonox BPIC-C75 71 days

1 phr Trigonox C 56 days

Cure Characteristics in Hot Press Moulding

In a standard Hot Press Moulding compound based on a high reactive orthophthalic polyester resin with calciumcarbonate as filler and magnesium oxide as thickening agent, the following application characteristics were determined:

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Unsaturated Resin,

Vinyl Ester Resin,

Epoxy Resin,

Gel coat resin,

The glass fiber,

Curing agent