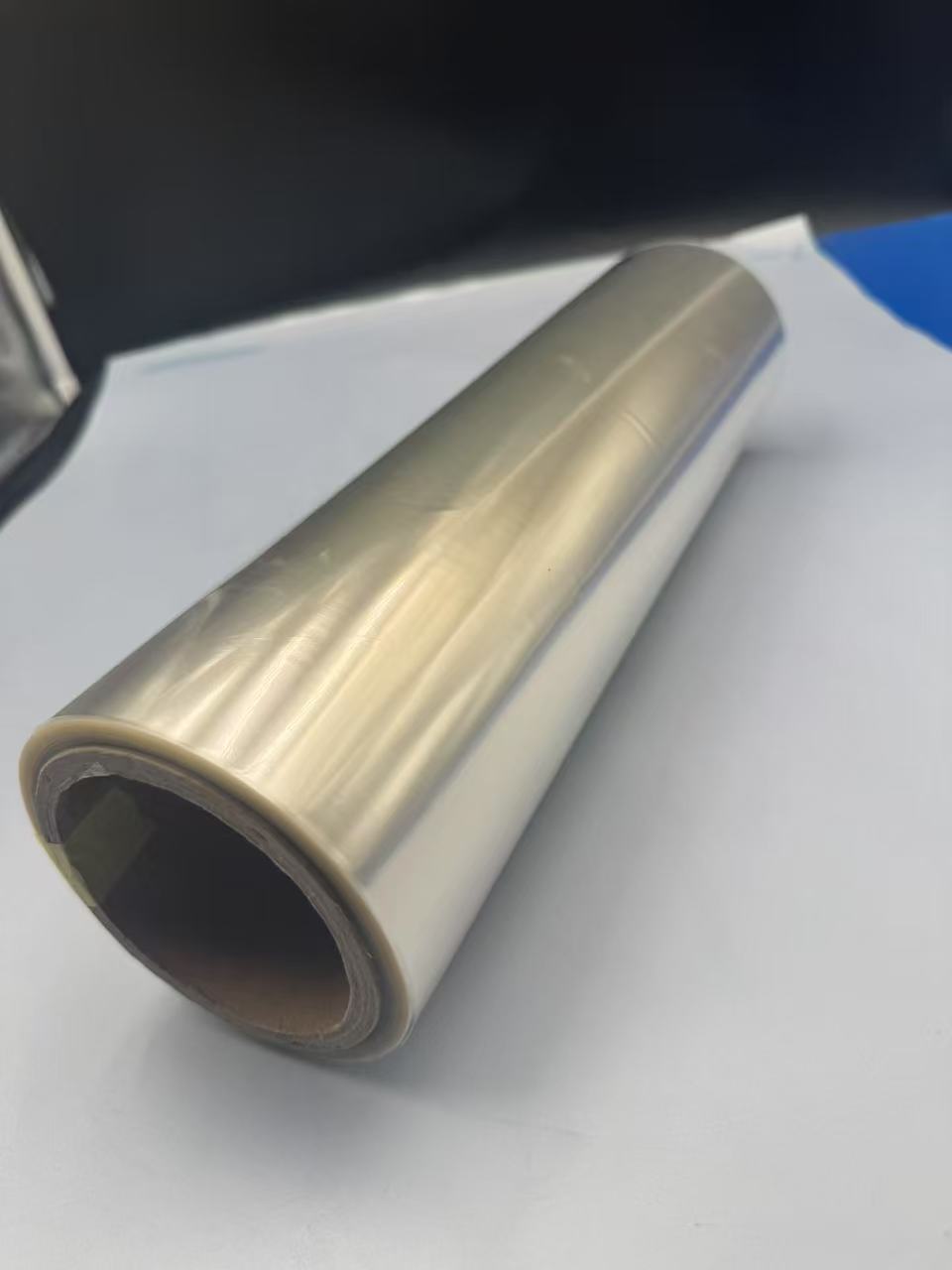

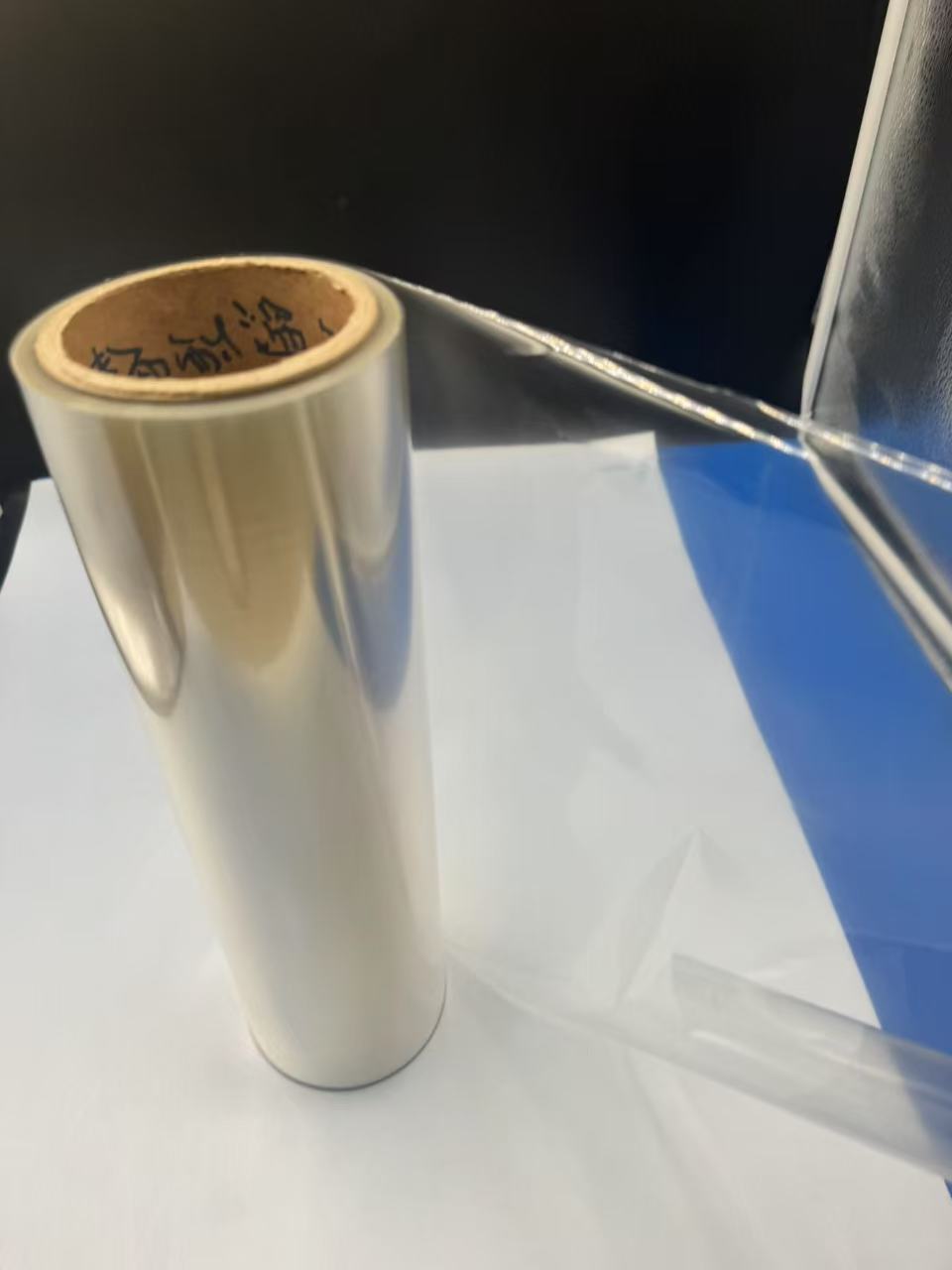

Polylactic Acid (PLA) film, derived from renewable resources like corn starch or sugarcane, has gained prominence as a biodegradable alternative to traditional petroleum-based plastics. Among its variants, transparent high-temperature PLA film stands out for its unique combination of clarity, heat resistance, and eco-friendliness. This article examines the defining characteristics of this material and its practical applications across various industries. With evidence-based insights and vivid examples, we’ll uncover how transparent high-temperature PLA film is reshaping the landscape of sustainable materials.

Key Properties of Transparent High-Temperature PLA Film

Transparent high-temperature PLA film is a bio-based polymer engineered to overcome the limitations of standard PLA, particularly its sensitivity to heat. Below are its core properties that make it a compelling choice:

Applications of Transparent High-Temperature PLA Film

The versatility of transparent high-temperature PLA***film shines through in its wide-ranging applications, from food packaging to industrial uses. Below, we explore its practical roles with detailed examples and technical grounding.

1. Food Packaging: Hot-Fill and Microwaveable Solutions

One of the most exciting uses of high-temperature PLA film is in food packaging that requires heat resistance. In hot-fill applications, such as sauces or soups packaged at 85°C–95°C, PLA***film serves as a lid or pouch material. Its thermal stability prevents warping, while its clarity enhances product visibility. Tests have shown that a 30-micron annealed PLA film maintains seal integrity under these conditions, with peel strengths averaging 10 N/15 mm.

For microwaveable containers, PLA film lids allow consumers to reheat meals without transferring them to another dish. A real-world example is a ready-to-eat meal tray sealed with a transparent PLA***film lid, which withstands 100°C for 2–3 minutes without compromising its structure—an eco-friendly alternative to traditional plastic films.

2. Fresh Produce Packaging: Balancing Breathability and Protection

The moderate barrier properties of PLA film make it ideal for packaging fruits and vegetables, where excessive sealing can trap moisture and accelerate spoilage. A perforated PLA***film wrap around strawberries, for instance, allows air exchange while protecting the fruit from physical damage. Its transparency highlights the freshness of the produce, appealing to consumers in supermarkets. Studies indicate that PLA film extends the shelf life of leafy greens by up to 10 days under refrigerated conditions, a testament to its practical utility.

3. Beverage Cups and Lids: Sustainable Alternatives

High-temperature PLA film has revolutionized the disposable cup industry by replacing polystyrene or polyethylene-lined lids. Transparent PLA***film lids for hot coffee cups, capable of enduring temperatures up to 105°C, offer a compostable solution without sacrificing functionality. A notable case is a café chain switching to PLA film lids, reducing its plastic waste by 20 tons annually while maintaining customer satisfaction with clear, spill-proof designs.

4. Medical and Pharmaceutical Uses: Sterile and Safe Packaging

In the medical field, PLA film’s biodegradability and clarity find niche applications, such as sterile wraps or temporary packaging for single-use devices. High-temperature variants can be sterilized at moderate heat (e.g., 100°C) without degrading, making them suitable for items like bandages or syringes. While PLA’s barrier properties limit its use for long-term storage, its transparency allows for easy inspection of contents, and its compostability aligns with healthcare’s growing sustainability goals.

5. Industrial and Consumer Goods: Shrink Films and Labels

High-temperature PLA film excels as a shrink wrap or label material due to its ability to conform tightly to shapes when heated. For example, a PLA***film sleeve label on a glass bottle shrinks uniformly at 90°C–110°C, offering a sleek, transparent finish that highlights branding. Its tensile strength ensures the film stays intact during application, while its biodegradability appeals to eco-conscious brands. In industrial settings, PLA film wraps protect small components during shipping, degrading harmlessly after use.

Challenges and Innovations

Despite its advantages, transparent high-temperature PLA film faces challenges that researchers and manufacturers are actively addressing. Its heat resistance, while improved, still lags behind PET or PP for extreme conditions (e.g., autoclaving at 121°C). Solutions include blending PLA with heat-resistant bio-polymers like polyhydroxyalkanoates (PHA) or adding nucleating agents to boost crystallinity, pushing the HDT closer to 130°C.

Cost is another hurdle—PLA film production remains 20–30% more expensive than conventional plastics due to raw material and processing costs. However, economies of scale and technological advancements, such as optimized extrusion methods, are gradually closing this gap. A pilot project in Europe demonstrated that high-volume production of PLA***film reduced costs by 15%, signaling a promising future.

Barrier properties also pose limitations for long-shelf-life goods. Innovations like coating PLA film with bio-based nanocellulose or wax layers have lowered OTR to below 200 cc/m²/day, expanding its potential in food preservation.

Real-World Impact and Future Outlook

The adoption of transparent high-temperature PLA film is transforming industries with tangible results. A bakery chain using PLA***film trays for pastries reported a 30% increase in customer preference for their “green” packaging, boosting sales. In the beverage sector, a compostable PLA film lid initiative cut landfill waste by 10,000 units monthly for a single vendor.

Looking ahead, PLA film’s role will grow as sustainability regulations tighten. Its ability to balance performance with environmental responsibility positions it as a leader in the shift toward circular economies. Imagine a world where every takeaway container or product wrap is both functional and compostable—high-temperature PLA***film is paving the way.

Conclusion

Transparent high-temperature PLA film embodies the fusion of innovation and sustainability. Its enhanced heat resistance, optical clarity, biodegradability, and mechanical strength make it a versatile material for modern applications, from food packaging to industrial uses. While challenges like cost and barrier performance persist, ongoing advancements are unlocking its full potential. As industries and consumers alike embrace eco-friendly solutions, PLA***film stands as a beacon of progress, proving that performance need not come at the planet’s expense.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film ,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products