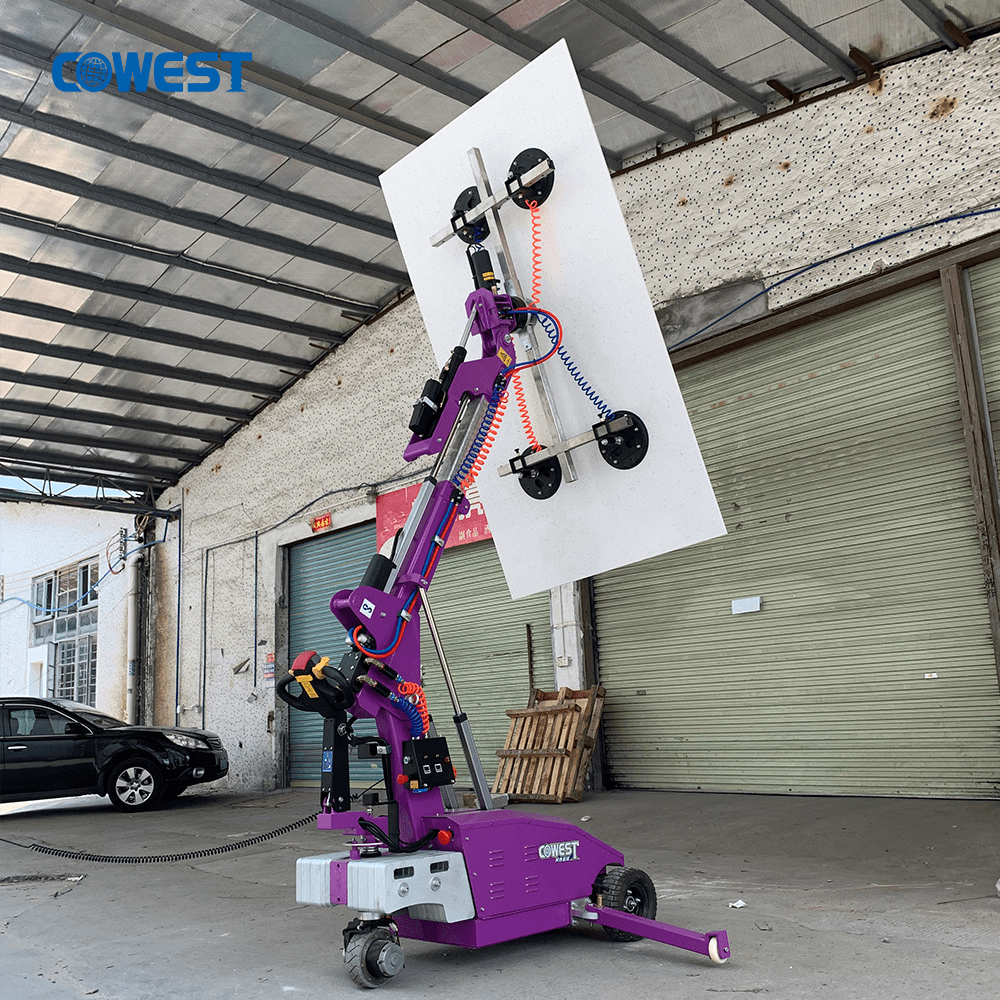

The WSR series of Smart Glass Installation Robot is a Glass Installation Equipment developed by our company that combines the functions of gripping, walking, lifting, Tilting and rotation by Automatic. It can be used for the Install Glass Curtain Wall , Install Glass Windows ,Install aluminium decorative panels, prefabricated concrete walls, marble and other panels on the outside of buildings or within floors. Compared to the traditional glass crane or large crane for installation, this series of glass installation lifter is small and agile, multi-functional, equipped with distance measuring and anti-tip safety devices, and optional wireless remote control to achieve one-person operation; This Glass Install Machine power supplied by 2 picese of big capcity Batteries it can working 6~8 hours continuity. it can also enter the engineering lift to install glass curtain walls indoors, greatly improving operational efficiency and safety. The WSR 400mini Glass Installation Robot is the smallest model in this series. But it's a excellet Install Glass Curtion Wall Lifter.

It has two model of this series , they have shorter body and lighter weight, Usually it can be enter microbus then transports to every construction site , it is a good assistant as the Install Glass Curtion Wall lifter.

This is our old model. The new model has added a passenger pedal. Here is the link:https://www.cowestmac.com/glass-installation-manipulator/63276903.html

1. Integrated Functionality: These robots combine the capabilities of gripping, walking, lifting, tilting, and rotating through automation, making them versatile tools for various installations such as glass curtain walls, windows, aluminum decorative panels, prefabricated concrete walls, and more.

2. Compact Design and Agility: Smaller and more maneuverable than traditional glass cranes, these robots offer enhanced flexibility for installations both outdoors and indoors, including use in elevators for indoor glass curtain wall installations.

3. Safety Features: Equipped with distance measuring devices and anti-tip safety mechanisms, ensuring safe and precise operations during installations.

4. Ease of Operation: Optional wireless remote control allows for single-person operation, streamlining the installation process and reducing labor needs.

5. Long Battery Life: Operated by two high-capacity batteries, these robots can work continuously for 6 to 8 hours, enhancing operational efficiency.

6. Portability: The compact design, particularly the WSR400-MINI model, enables easy transport via mini-buses to any construction site, making it highly adaptable to various project locations.

7. Load Handling: With a load capacity of up to 380kg, these robots are capable of handling a wide range of materials, including glass, marble, and tiles.

8. Versatile Movement and Adjustment: Features like electric hydraulic tilt, pad frame vertical movement, boom in/out, powered arm up/down, lateral side shift, and pad frame tilt provide precise control over the robot's movements, facilitating efficient installation tasks.

9. Robust Construction: The inclusion of suction cups, pressure gauge, and digital indication for vacuum ensures secure handling and placement of heavy materials.

In summary, the WSR series of Smart Glass Installation Robots is designed for efficiency, safety, and adaptability, making them indispensable tools in the field of glass and material installation.

Model: WSR400-MINI

Load Capacity: 380kg

Lifting Height: 3000mm

Driving Speed: 0-4km/h

Rated Power: 1.2kw

Drive Model: 24V, Rear Drive

Climbing Capacity: 15%

Vacuum Indication: Digital and Pressure Gauge

Suction Cups: 4, Diameter of 300mm each

Continuous Working Time: 4h-8h

Battery: DC12V x 2 x 100Ah

Battery Charger: AC110V-220V

Height Forward Extension: 500mm

Electric Hydraulic Tilt: Forwards & Backwards from Vertical to Horizontal

Movement (Automatic):

1. Pad Frame Vertical Up/Down: 180°

2. Boom In/Out:

3. Powered Arm Up/Down:

4. Lateral Side Shift: 100mm

5. Pad Frame Tilt Left/Right: 90° Manual

6. Pad Frame Rotation: 360° Manual

Usages: Mainly used for handling, moving, and installing glass, marble, tile, etc.

About us

Guangzhou Cowest Machinery Equipment Ltd was established in 2008,which is a professional Vacuum handling equipment research and development, production, sales and service in one manufacturing enterprise. Our products are used in many industries such as Construction, Glass manufacturing, Chemical industry, Pharmaceutical industry, and food industry, and are exported to Europe, America, the Middle East, Southeast Asia and other regions around the world.

We have own R&D team and core product technology, and have obtained more than 30 product patents, including Movable Vacuum tube lifter with Fold Crane, Glass installation Robot, Stone Road installation manipulator ect. These products are one of the best in the world, and they are used in many famous enterprises and projects: Dunlop Tires, Nescafe, Brother Printer, IBM, Lipan Paint, Kohler and other products of the production line handling palletizing. Our products also participated in many famous large-scale construction projects for Glass installation .such as the glass installation projects of Beijing Library, Guangzhou Tower,Hong Kong Pacific Place,the United States Metropolis and Beijing Airport ,etc.In addition, we also cooperate with many famous construction machinery giant enterprises: Manitou, Zoomlion, Zhejiang Dingli, Sany Machinery, XCMG Group, etc. to provide technical support and accessory products.

Our company has always adhered to the philosophy of "only the best, the best in the industry", and has learned on a wide range of global technical expertise to create rock-solid product quality and safer, more personalised products that customers can buy with confidence and comfortable to use, making handling problems easy!

|

Packaging Detail: |

by Flexible Package, Seaworthy Package |

|

Delivery Time: |

15-30 days |

1.How can customer buy parts once the Vacuum Glass lifter break down?

Thes Glass lifter adopts most of the common parts of hardware.You can buy the parts in your local hardware market or forklift parts shop.

2.How can customer repair the Glass lifter.

One of the great advantage of Glass lifter is with very very low failure rate.Even it breaks down,we can guide to repair it by

video and repair instruction.

3.What is the battery life span?

The lift span of the battery can be 4 years if you maintain it as per our maintanance manual.

4.How long is the quality guarantee of the Glass lifter?

One year quality guarantee including battery.Wheels are not included.If it breask down within one year,we can send the parts free of charge to you.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

glass lifting equipment,

Glass Installation Robot,

Stone Paving Equipment,

Vacuum tube Lifter for cartons,

Glass Vacuum Lifter,

Glass Installation Lifter