ZHEJIANG TOMAN INTELLIGENT TECHNOLOGY CO., LTD was founded in 2006, mainly engaged in the research and developments, manufacturing and service of GAER AUTOMATIC EQUIPMENTS, BEARING AUTOMATION EQUIPMENTS, INTELLIGEN COMPONENTS, Industrial Internet Application and System Integration based on Industry 4.0.

ZHEJIANG TOMAN INTELLIGENT TECHNOLOGY CO., LTD was founded in 2006, mainly engaged in the research and developments, manufacturing and service of GAER AUTOMATIC EQUIPMENTS, BEARING AUTOMATION EQUIPMENTS, INTELLIGEN COMPONENTS, Industrial Internet Application and System Integration based on Industry 4.0.

Speciallized in the production of all kinds of GAER CUTTING MACHINE TOOLS AND AUTOMATIC PRODUCTION LINE.

Provide the customers with high efficiency, high precision, cost-effective comprehensive solutions of gear cutting.

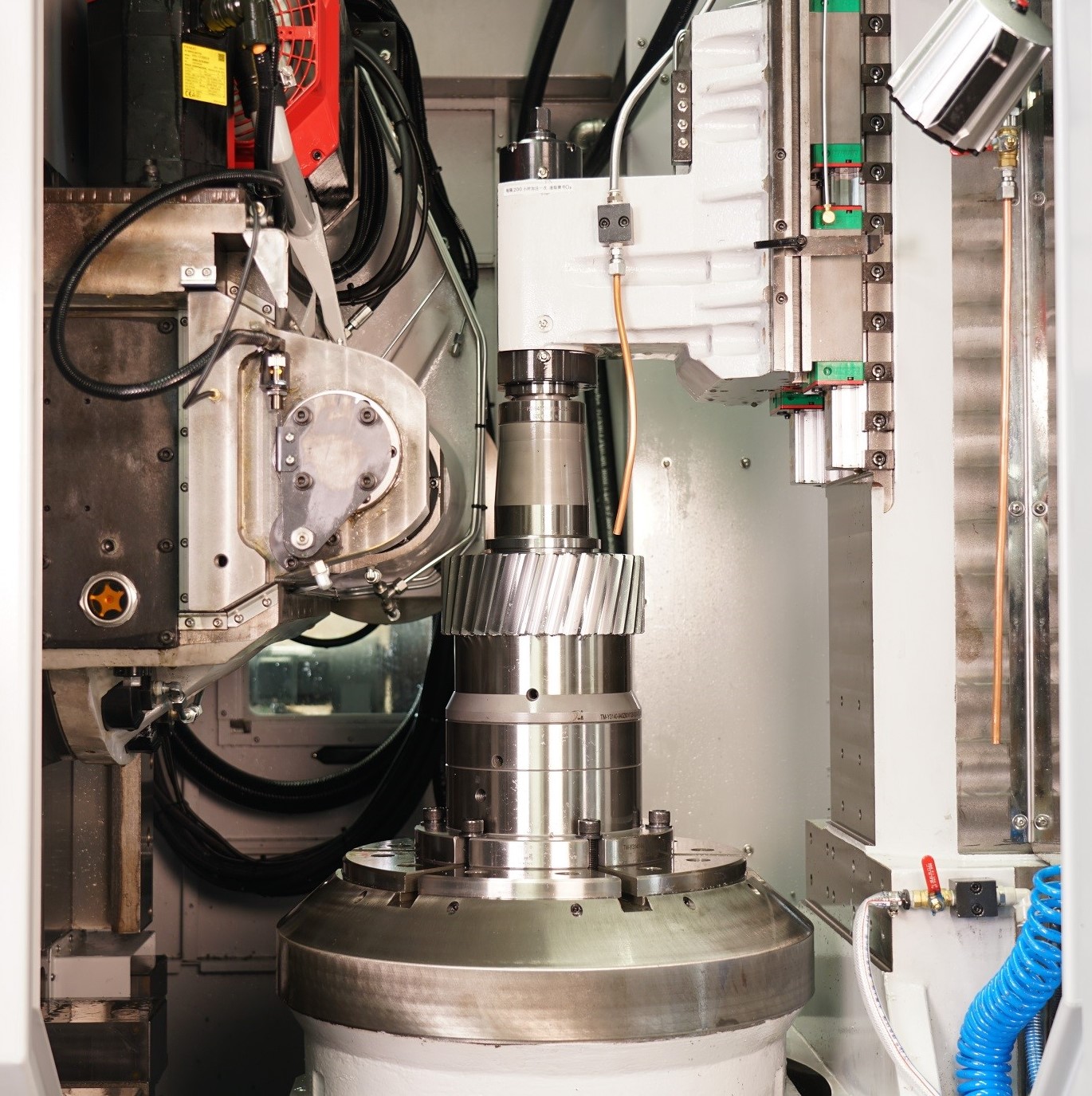

Y3110 CNC6

An Engery Saving and Complete Dry Cut Hobbing Machine

FANUC numerical control system and servo drive, system reliability, simple operation

Automatic loading/unloading material device

(Dry Cutting Hobbing Machine or Wet/Dry Cut Hobbing Machine is optionally available.)

|

Max. Workpiece Diameter: Φ100 mm |

|

Max. Module: 3 |

MAIN TECHNOLOGY PARAMETER

|

CNC Hobbing Machine |

Unit |

TMY3110 |

|

|

|

Dry hobbing |

|

Maximum workpiece diameter |

mm |

Φ100 |

|

Maximum module |

mm |

3 |

|

Worktable surface diameter |

mm |

Φ150 |

|

Hob maximum assemble diameterx length |

mm |

Φ110x150 |

|

Horizontal distance between hob center and worktable center |

mm |

5-145 |

|

Maximum hob axial movement amount |

mm |

130 |

|

Hob head slide travel (Z axis displacement) |

mm |

190-400 |

|

Max. swiveling angle of the hob head |

Deg |

±45° |

|

Hob spindle motor power |

KW |

7.5 |

|

Maximum hob spindle rotate speed(B axis) |

rpm |

3000 |

|

Maximum worktable rotate speed(C axis) |

rpm |

400 |

|

Radial feed speed(X axis)(stepless) |

mm/min |

1-2000 |

|

Radial maximum rapid moving speed(X axis) |

mm/min |

8000 |

|

Axial feed speed(Z axis)(stepless) |

mm/min |

1-2000 |

|

Axial maximum rapid moving speed(Z axis) |

mm/min |

8000 |

|

Tangential travel feed speed(Y axis)(stepless) |

mm/min |

1-1000 |

|

Tangential maximum rapid travel speed(Y axis) |

mm/min |

3000 |

STANDARD CONFIGURATION

|

Hob arbor assembly ( Φ32) |

hydraulic system |

|

Hob arbor automatic clamping device |

NC controller system |

|

Workpiece automatic clamping device |

NC data memory card |

|

Spindle positioning |

Operational software |

|

Fully-enclosed safeguards |

Residual-current circuit breaker |

|

Woking light |

Hands action button |

|

Three colour lights indicate machine status |

RS232C connector |

|

Workpieces counter |

Air conditioner for electric cabinet |

|

Main spindle ampere meter |

Chip conveyor |

|

Chip cart |

Automatic lubrication system |

|

Cutting oil tank (Wet hobbing ) |

Mist collector |

|

Cold spray gun (Wet hobbing ) |

The sizing block for machine adjustment |

OPTIONAL CONFIGURATION

|

Automatic loading/unloading material device |

Workpiece clamping |

|

Automatic material storage |

Workpiece rough locator device |

|

Deburring device |

Automatic tooth align device |

|

Independent hob adjustment device |

Oil cooling device |

|

Hob arbor assembly:(metric system:Φ10, Φ13, Φ22, Φ27, Φ40),(Inch system: Φ16, Φ22.225, Φ26.988, Φ38.1) |

|

APPLICATIONS:

MAIN FEATURES

2. Adopted modular design, each functional components can be quickly combined into models with different functions, to meet the customer personalized, fast delivery requirements.

3. Easy to access and maintenance components with combining the hydraulic, lubricating and pneumatic components onto the machine tool.

4. Has fault self-diagnosis, spindle overload automatic monitoring and alarm protection functions etc.

5. Customers can purchase automatic loading and unloading device, automatic bin, deburring device and rough positioning device according to the processing needs.

6. The dual-station loading and unloading manipulator design of the processing position and the replacement position, compact and reliable structure, and realizes less and unmanned processing, to improve the processing efficiency of the machine tool.

WHY CHOOSE US?

2. Certification--CE/ISO, First prize of science and technology award, National key high tech enterprise and so on.

3. Quality Control--Quality checks to promise stable quality and high reliability for you.

4. Best Material--Insist on choosing top materials.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Gear Hobbing Machine,

Gear Shaving Machine,

Gear Automatic Production Line,

Gear Cutting Machines,

Gear Hobbing/Chamfering Compound machines ,

Bearing Turning Machine