Matting agents are additives used in coatings to reduce gloss and improve surface properties such as scratch resistance, chemical resistance, and

hiding power. They are commonly used in UV-cured coatings to achieve a matte finish. There are various types of matting agents available, including

silica, polyethylene, and wax-based agents.

UV70C is a specific type of matting agent that is a wax-based dispersion designed for UV-curable coatings. It offers excellent scratch resistance and matting

efficiency, making it suitable for a wide range of applications, including wood, plastics, and metal coatings.

Compared to other types of matting agents, UV70C is known for its high efficiency, low viscosity, and ease of use. It is also compatible with various resin systems,

including acrylates, epoxies, and polyurethanes.

Overall, matting agents for UV coatings vary in their properties and performance. When selecting a matting agent, it is essential to consider factors such as the desired

level of matting, substrate, and application method. UV70C is a popular choice for its efficiency and versatility, but other options may be more suitable depending on the

specific requirements of the coating.

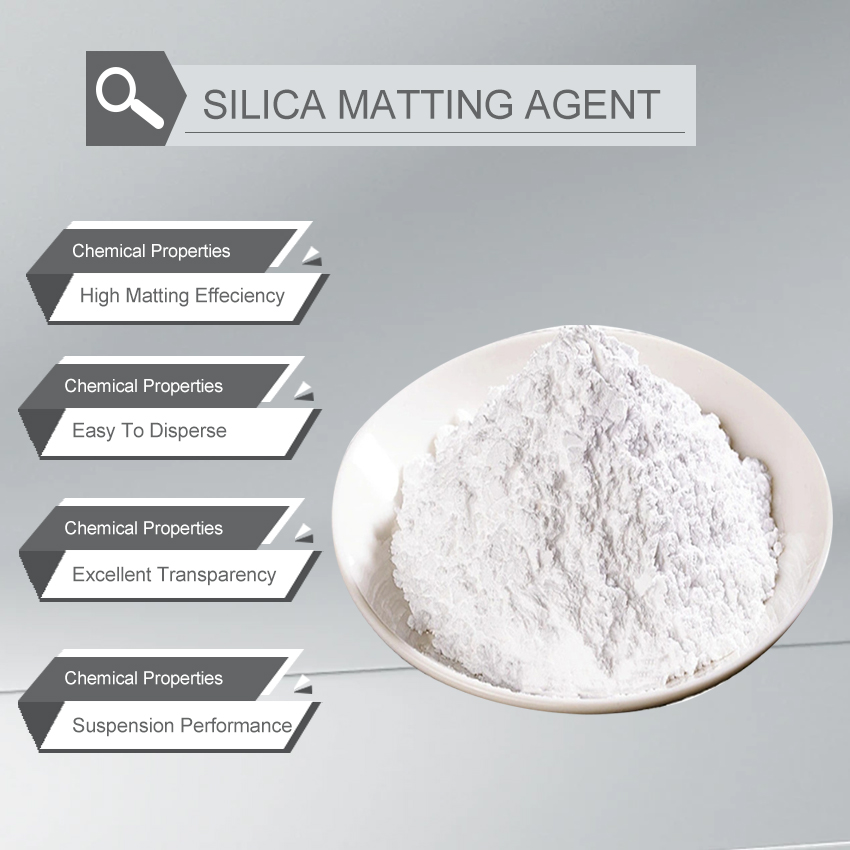

1. It has high extinction efficiency and good compatibility with most resins.

2. It can be widely used in low VOC system because of its low oil absorption value and low thixotropy.

3. It is easy to disperse and not easy to settle and agglomerate when it is directly added into the system.

4. Study on unstable foam of coating system.

5. Improve the scratch resistance of the film without affecting the mechanical properties of the film.

6. It can obtain excellent performance and reduce production cost at the same time.

Chemical Data

|

Item |

SS-U70 |

Loss on drying(105℃,2Hrs) |

≤5.0 |

|

Content of sio2(dry basis) %, |

≥99.0 |

Ignition loss(1000℃,2Hrs) |

≤13.0 |

|

Porosity ml/g |

1.8-2.0 |

Whiteness |

≥90.0 |

|

Oil absorption, g/100g , g/100g |

230-270 |

PH(5% Liquor) |

6-7 |

|

Particle Size, um(Malvent,D50) |

6-7 |

Surface Treatment |

Organic |

Application:

UV floor wood Coatings, UV Plastic Coaitngs, UV Printing Inks.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Paint Matting Agent ,

Silica Matting Agent ,

Inkjet Receptive Coating,

Nano Alumina,

Teflon Heater,

Anticorrosion Pigments