Classification of Aluminum Extrusion Dies

1. Classified by the section shape of the die hole compression zone

It can be divided into: flat die, conical die, flat cone die, streamlined die and double cone die, etc.,

2. Classified by the types of extruded aluminum profiles.

It can be divided into bar molds, ordinary solid profile molds, wall panel molds, variable-section profile molds, pipe molds, and hollow profile molds.

3. Classified by the number of die holes

It can be divided into single-hole die and multi-hole die;

4. Classified by the extrusion method and process characteristics

It can be divided into hot extrusion die, cold extrusion die, hydrostatic extrusion die, reverse extrusion die, continuous extrusion die, water cooling die, wide expansion die, horizontal extrusion Machine molds and vertical extrusion machine molds, etc.

5. Classified by the mold structure

It can be divided into integral mold, hollow die, removable mold, movable mold, tongue-shaped combined mold, plane split combined mold, embedded mold, fork mold, front mold, protective mold, etc.

6. Classified by the shape and structure of the mold

It can be divided into a cone mold with an inverted cone, a cylindrical mold with a boss, a cone mold with a positive cone, a conical-middle cone ring mold with an inverted cone, and an inverted cone mold. Cylindrical-conical molds for cones, reinforced molds, etc.

The Difference Between Solid Die and Hollow Die

Solid Die

The solid die is relatively simple, as long as the split hole is designed, the aluminum handle is squeezed out of the flat flag hole to form a cross section after mixing.

Like aluminum flat strips, aluminum rods, some special-shaped materials, etc.

Hollow Die

Hollow dies are generally combined by two combined molds, so that the cavity can be formed by splitting the flow through the working belt during extrusion, such as aluminum shells and round tubes.

For ordinary extrusion dies, to produce hollow profiles, a splitter die must be used, which consists of an upper die and a lower die. The upper die is generally used to guide flow and position the hollow part of the hollow profile. The lower mold is the outer surface working belt and empty knife.

Most of the non-hollow profiles use solid dies. Generally speaking, there is only one mold including diversion and working belts. Of course, there are special cases. Here we only explain the general production conditions.

What are the characteristics of high-quality aluminum profile molds?

1. High precision: High-quality aluminum profile molds have very high precision, which can ensure that the products produced are accurate in size and regular in shape.

2. Durable: High-quality aluminum profile molds are usually made of high-strength materials, with good wear resistance and corrosion resistance, and long service life.

3. Good thermal conductivity: Aluminum has good thermal conductivity, which is very important to ensure uniform temperature of the mold during the production process and prevent internal stress and deformation of the product.

4. High production efficiency: High-quality aluminum profile molds have good fluidity and plasticity, which can greatly improve production efficiency.

5. Simple maintenance: High-quality aluminum profile molds have a simple structure and are easy to maintain and clean.

6. Environmental protection: Aluminum is a recyclable material. Using high-quality aluminum profile molds can not only save resources, but also benefit environmental protection.

7. Energy saving: Compared with molds made of other materials, aluminum profile molds can better retain heat during the production process, thus saving energy.

8. Various shapes: High-quality aluminum profile molds can be designed in various shapes and specifications as needed to meet various production needs.

If you are looking for Architectural aluminum profile mold, Decorative aluminum profile mold, Industrial aluminum profile molds and Furniture aluminum profile mold, we are the perfect aluminium extrusion mould manufacturer from China for you.

The working principle of extruded aluminum profile mold mainly includes the following steps:

1. Preheating: First, preheat the aluminum profile and extrusion die to a certain temperature.

2. Extrusion: The preheated aluminum profile is put into the extruder and extruded through the cavity of the mold under high pressure to form the desired profile shape.

3. Cooling: The extruded aluminum profile needs to be cooled to fix its shape.

4. Cutting: The cooled aluminum profile is cut to the required length.

5. Heat treatment: In order to improve the hardness and strength of aluminum profiles, heat treatment is usually required.

6. Surface treatment: As needed, the surface of the aluminum profile may need to be frosted, anodized, electrophoretic painted, powder sprayed, etc.

In the whole process, the function of the extrusion die is to determine the shape of the extruded aluminum profile through the shape of its internal cavity during the extrusion process. The design and production of molds directly affect the quality and production efficiency of aluminum profiles.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Industrial Aluminum Material,

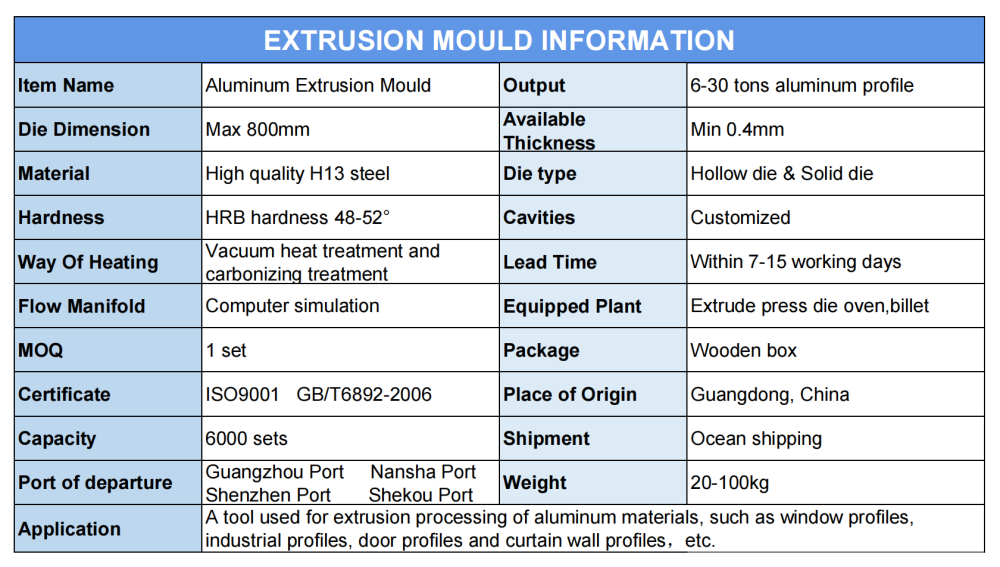

Aluminum Profile Extrusion Mold,

Aluminium Extrusion Mould,

Aluminum Extrusion Die,

Aluminium Profile,

Aluminium Extrusion Profile