Overview of Ferrosilicon Products:

Ferrosilicon is an iron alloy composed of iron and silicon. Ferrosilicon is an iron silicon alloy made by smelting coke, steel shavings, quartz (or silica) as raw materials in an electric furnace.

Factors affecting the price of ferrosilicon products:

1. The price of raw materials.

2. Production of ferrosilicon products (supply exceeds demand, prices decrease).

3. Import and export volume.

4. Electricity price factors.

The use of ferrosilicon products:

1. Used as a deoxidizer and alloying agent in the steelmaking industry. In order to obtain steel with qualified chemical composition and ensure the quality of steel, deoxidation is carried out in the final stage of steelmaking. The chemical affinity between silicon and oxygen is high, so ferrosilicon is a strong deoxidizer for precipitation and diffusion deoxidation in steelmaking. Adding a small amount of silicon to steel can significantly improve its strength, hardness, and elasticity. Therefore, ferrosilicon is also used as an alloying agent in the smelting of structural steel (containing 0.40-1.75% silicon), tool steel (containing SiO.30-1.8%), spring steel (containing SiO.40-2.8%), and silicon steel for transformers (containing 2.81-4.8% silicon). Simultaneously improving the morphology of inclusions and reducing the gas element content in molten steel is a new technology for improving steel quality, reducing costs, and saving iron. Specially suitable for deoxidation requirements of continuous casting molten steel, practice has proven that ferrosilicon not only meets the deoxidation requirements of steelmaking, but also has desulfurization performance and advantages such as high specific gravity and strong penetration.

In addition, in the steelmaking industry, silicon iron powder is often used as a heating agent for steel ingot caps to improve the quality and recovery rate of steel ingots due to its ability to release a large amount of heat at high temperatures.

2. Used as an inoculant and spheroidizer in the cast iron industry. Cast iron is an important metal material in modern industry. It is cheaper than steel, easier to melt and smelt, and has excellent casting performance and much better seismic resistance than steel. Especially ductile iron, its mechanical properties reach or approach those of steel. Adding a small amount of ferrosilicon to cast iron can prevent the formation of carbides in iron, improve the precipitation and spheroidization of graphite. Therefore, in the production of ductile iron, ferrosilicon is an important inoculant (helping to precipitate graphite) and spheroidizing agent.

3. Used as a reducing agent in the production of ferroalloys. Not only is there a high chemical affinity between silicon and oxygen, but the carbon content of high silicon ferrosilicon is also very low. Therefore, high silicon ferrosilicon (or silicon alloy) is a commonly used reducing agent in the production of low-carbon ferroalloys in the ferroalloy industry.

4. 75 # ferrosilicon is commonly used in the high-temperature smelting process of magnesium metal in the Pidgeon process, where CaO is added Replacing magnesium in MgO consumes about 1.2 tons of ferrosilicon for every ton of metallic magnesium produced, which plays a significant role in the production of metallic magnesium.

5. For other purposes. Finely ground or atomized silicon iron powder can be used as a suspended phase in the mineral processing industry. It can be used as a coating for welding rods in the welding rod manufacturing industry. High silicon ferrosilicon can be used in the chemical industry to manufacture products such as silicone.

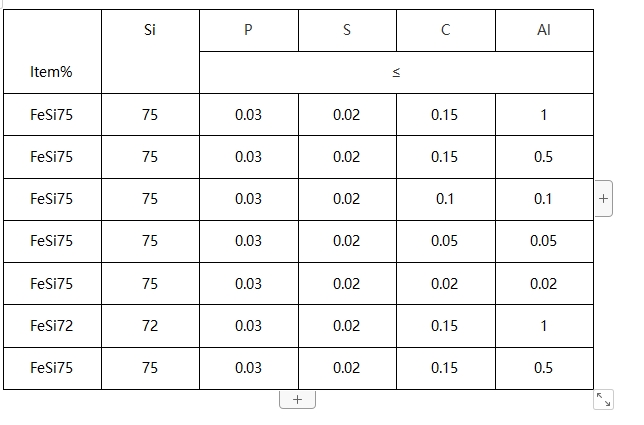

Among these applications, the steelmaking industry, foundry industry, and ferroalloy industry are the largest users of ferrosilicon. They consume over 90% of silicon iron together. Among various grades of ferrosilicon, 75% ferrosilicon is currently the most widely used. In the steelmaking industry, approximately 3-5 kg of 75% silicon iron is consumed for every 1 ton of steel produced.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Ferrosilicon alloy,

Silicomanganese alloy ,

Metal silicon alloy,

calcium-silicon,

Rare earth silicon magnesium alloy,

Ferromanganese alloy