Work Principle Description

After filtering and heating, the air enters into the hot air distributor at the top of the centrifugal spray dryer, and the hot air will spirally and evenly goes into the drying chamber. The material liquid via high-speed centrifugal atomizer rotates into extremely thin vaporific liquid globule and parallelly flows with the hot air, and then the liquid will be dried into powdery products in a very short time (5-10 seconds). The waste gas after filtering will be expelled through the fan. For the wet organic solvent materials, the spray drying machine can be designed with closed cycle process. It can utilize cyclic nitrogen to dry the materials.

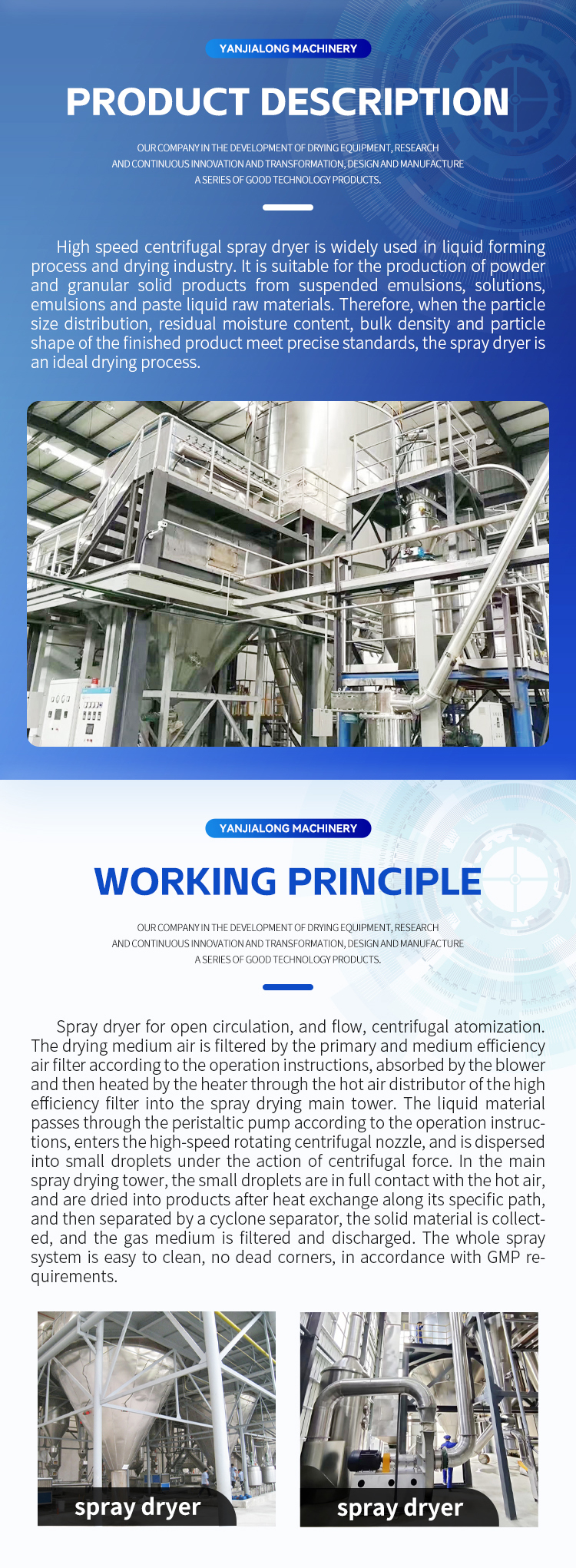

Machine Pictures

Application of Spray Dryer for PF resin

We are the spray dryer national stardard maker, our spray dryer is widely used for sheep blood, bovine(ox) blood, Pig blood etc.

With high drying efficiency, large production, low operation cost, good product quallity features, our spray dryer is welcomed by all home and aborad customers.

Features

Technical Specifications of Centrifugal Spray Drying Machine

|

Item/Model |

LPG |

|||||||||

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

|||||

|

Inlet temperature(℃) |

≤350 |

|||||||||

|

Outlet temperature (℃) |

80-90 |

|||||||||

|

Max. moisture evaporation (kg/h)* |

5 |

25 |

50 |

100 |

150 |

200-2000 |

||||

|

Drive type of centrifugal spray nozzle |

Compressed air drive |

Mechanical drive |

|||||

|

Rotation speed |

25000 |

22000 |

21500 |

18000 |

18000 |

15000 |

|

|

Diameter of spray disk(mm) |

50 |

102 |

108 |

108 |

150 |

180-340 |

|

|

Heat source |

Electricity |

Electricity |

Electricity |

Electricity + steam |

Electricity |

Depending on the user |

|

|

Max. electric heating power (kw) |

8 |

31.5 |

60 |

81 |

99 |

|

|

|

Outline dimensions L×W×H |

1.8×0.93×2.2 |

3×2.7×4.26 |

3.7×3.2×5.1 |

4.6×4.2×6 |

5.5×4.5×7 |

According to actual situation |

|

|

Dry powder recovery (%) |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

|

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

MVR evaporator,

Low temperature evaporator,

Sludge dryer,

wastewater evaporator ,

Power plant wastewater treatment,

spray dryer