Our factory is professional in manufacturing the liquid silicone injection molding machine (LSR molding machine /Injection machine of LSR),from 35T,55T,85T,120T,160T & 200T,Horizontal injection molding machine and vertical LSR injection machine we have.Together with liquid silicone mold and automation for your choosing.We also make the plastic injection molding machine and rotary plastic injection mold machine .

Silicone products are more and more popular nowadays.including solid silicone and liquid silicone .Solid silicone products are made by compressing machine;liquid silicone products are made by the liquid silicone rubber molding machine.

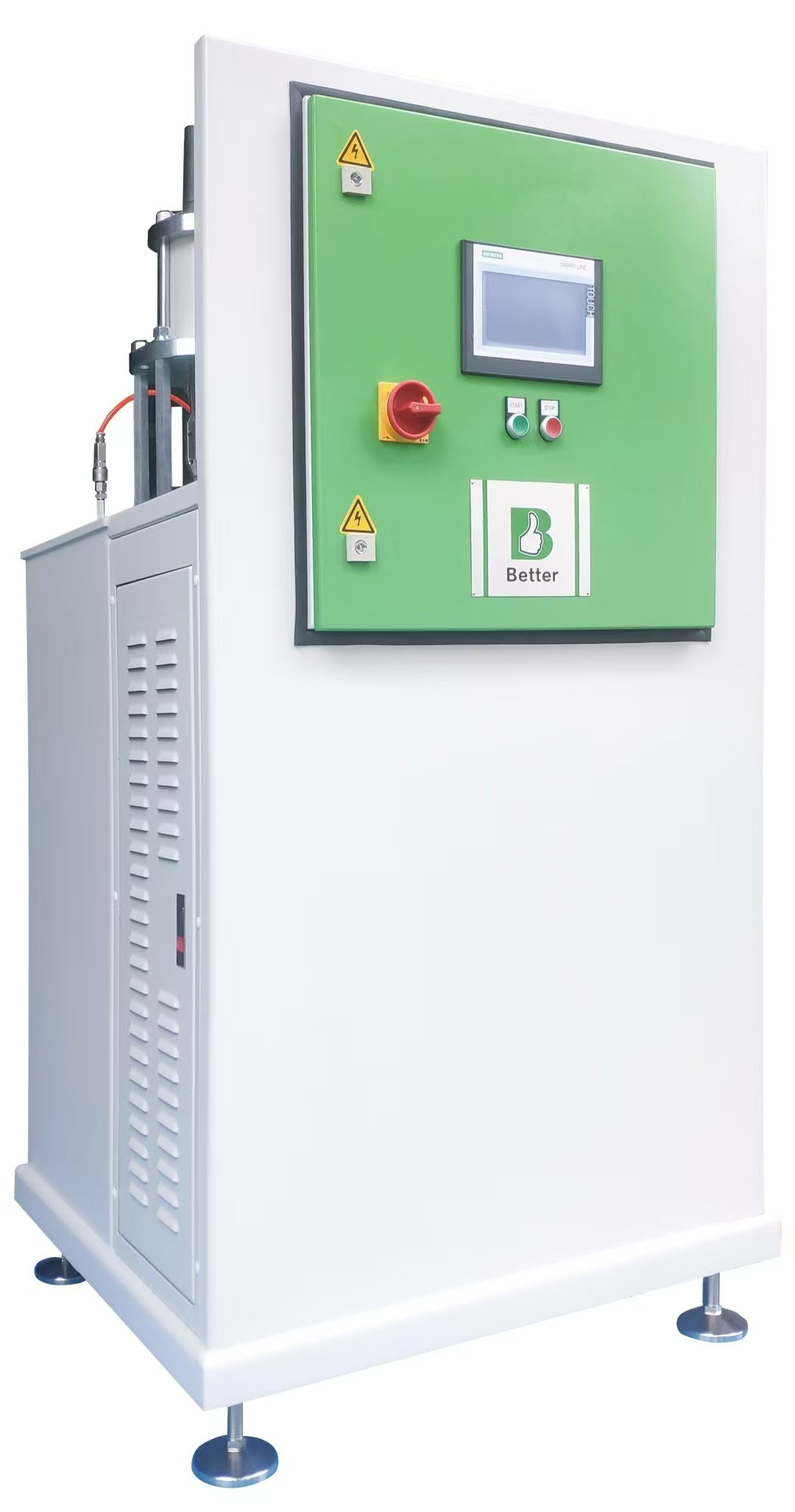

Vertical dosing unit is used for making the liquid silicone rubber product.And it works with the liquid silicone rubber injection molding machine and LSR mold.It is also called feeding machine.

Better-319 Dosing system

1)With the economical micro feeding system and the principle of AB synchronous cylinder, it is very stable and easy to control.

2)The feeding amount is 0-1,000g in 60s(depending on the material viscosity).It is only applicable to a 20L standard material barrel.

3)It is applicable to the production of most silicone rubber products in the industries such as power,infant and children supplies, sports, auto parts, electronic products, healthcare, and adult supplies.

Characters

1) It is designed according to the principle of the AB synchronous cylinder. With the same power source and hydraulic power,the feeding is stable and fast.

2)The high-precision color measurement is accurate and the color accuracy is higher enough to be identified by the chromatographic instrument.

3)By using the static mixing and dispensing technology,there is no dead corner for mixing and dispensing and it is convenient to clean and install.

THE HIGH-PRECISION (LSR) DOSING SYSTEM

1.All the parts are processed with the imported equipment with an original package to ensure the accuracy of the process parts.

2.All core parts are imported from Europe or America,which ensures the stability and service life of the machine.

3.Design for convenient maintenance:the displacement pump device is easy to disassemble.

4.A long life service sealing element

5.Function guarantee and external valve·

6.Detachable mixer·

7.Material shortage and over pressure alarm safety device

8.Reproducible color adjustment

9.The coating is optimized through a special material barrel supporting disk.

10.Material barrel emptying alarm

11.Provide users with special options for special actual needs。

12.Comply with international and European standards

13. 200-liter barrel can be changed to a 20-liter barrel.

14.The hard metal ball valve and high-speed steel piston rod with higher durability can be used for liquid materials with different viscosity.

15.Mixing section that can be cooled

16.Colorant and adding and metering device·

17.Feeding pump can work continously under material assistance.

18.Pressure gauge display in mixed materials

The two components, once mixed in the desired ratios, are metered to the injection unit by a special delivery system. Better partners with

several suppliers of this specialist equipment to provide a turn-key LSR solution. Or, if the customer already has existing LSR delivery

equipment, this can be easily interfaced to work with a suitably-equipped Better LSR machine.

https://www.lsrexpert-better.com/rubber-filling-machine/63467785.html

https://www.lsrexpert-better.com/rubber-filling-machine/63468050.html

https://www.lsrexpert-better.com/rubber-filling-machine/63467467.html

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Liquid silicone rubber injection molding machine,

Lsr injection molding machine,

Vertical Injection machine,

liquid silicone injection molding machine,

Silicone injection molding machine ,

Injection moulding machine