As an important part of the mold, its design, material selection, manufacturing process, and maintenance must be strictly controlled to meet the needs of efficient, high-precision production.

The manufacture of Mould Trim Line heads requires high-precision machining techniques, such as wire cutting, electric discharge machining (EDM), and laser cutting, to ensure the sharpness of the cutter head edges and the accuracy of the dimensions to meet the requirements of high-precision machining.

Insert Injection Molding Process is widely used in many fields such as Metal Stamping Dies, plastic molding, packaging material cutting, electronic component manufacturing, automotive parts production, etc. It is an important tool to ensure product accuracy and production efficiency.

How to maintain and care for the Insert Molding Process?

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

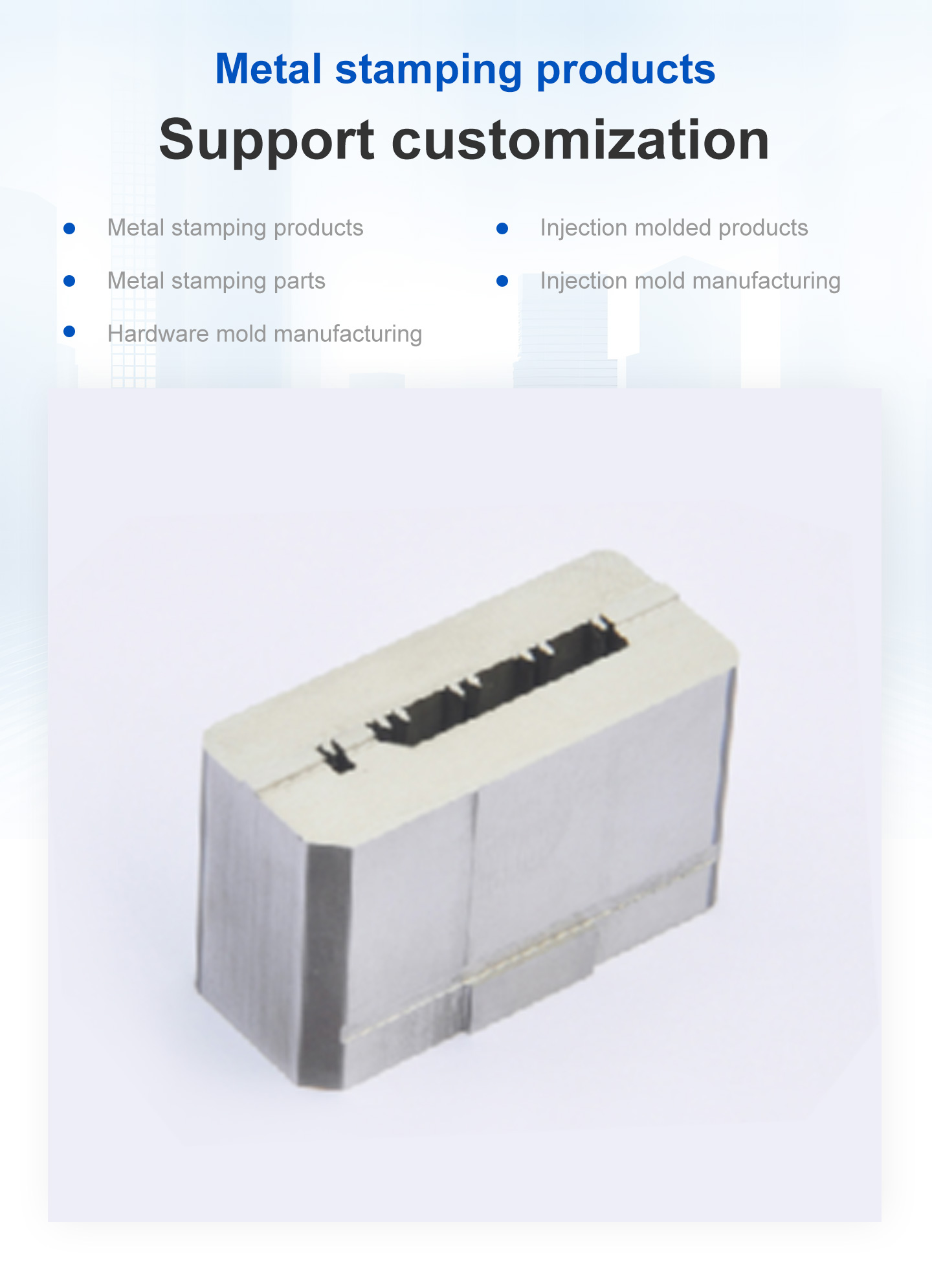

Main Product:

Hardware Mold,

Hardware Stamping Parts ,

Injection Molded Products,

Carbide Punches,

Mold Parts,

Injection Mold Manufacturing