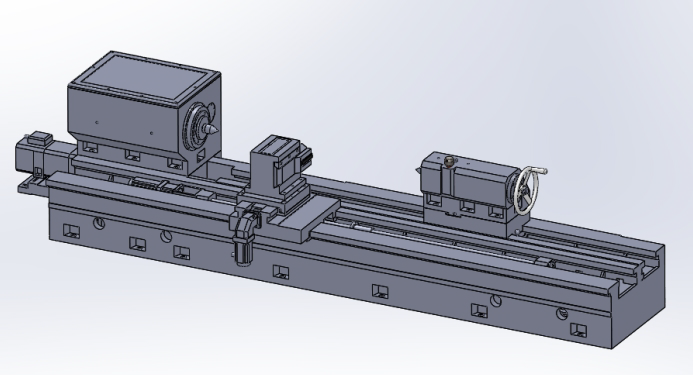

| Maximum machining diameter | Φ650mm |

| Workpiece length | 3000mm |

| Spindle speed | 1rpm~200rpm |

| Spindle center height | 1105mm |

| Spindle motor power | 30KW |

| Z-axis motor power | 5.2KW |

| X-axis motor power | 3.0KW |

| Z-axis feed speed range | 1~3000mm/min |

| X-axis feed speed range | 1~3000mm/min |

| Distance from spindle center to guide rail | 475mm |

| Distance from spindle center to tailstock center | 3000mm |

| Distance from spindle center to carriage | 275mm |

| Diameter of spindle end chuck | Φ650 |

| Spindle center | Morse No. 6 |

| Tailstock center | Morse No. 6 |

| Tailstock center load | 7000Kg |

| Tailstock sleeve stroke | 200mm |

| Surface roughness of fine turning outer circle | ≤Ra0.8μm |

| Fine turning outer circle roundness | ≤0.01 mm |

| Minimum unit of longitudinal and lateral movement | 0.001 mm |

| X-axis ball screw nominal diameter | Φ50 |

| Z-axis ball screw nominal diameter | Φ63 |

| Positioning accuracy A (X axis) | 0.012mm |

| Positioning accuracy A (Z axis) | 0.045mm |

| Repeat positioning accuracy R (X axis) | 0.007mm |

| Repeat positioning accuracy R (Z axis) | 0.01mm |

| Reverse difference B (X axis) | 0.006mm |

| Reverse difference B (Z axis) | 0.012mm |

| Installation size of machining tool | 300*45*45mm |

| Machine size (length*width*height) | 6250*1850*1800mm |

| Net weight of machine tool | 13000Kg |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Roller Lathe,

Roll Milling Machine,

Roll Grinding Machine,

Thread Milling Machine ,

Machining center,

Roll Ring Grinder