The Characteristics and Versatile Applications of Transparent PE Film

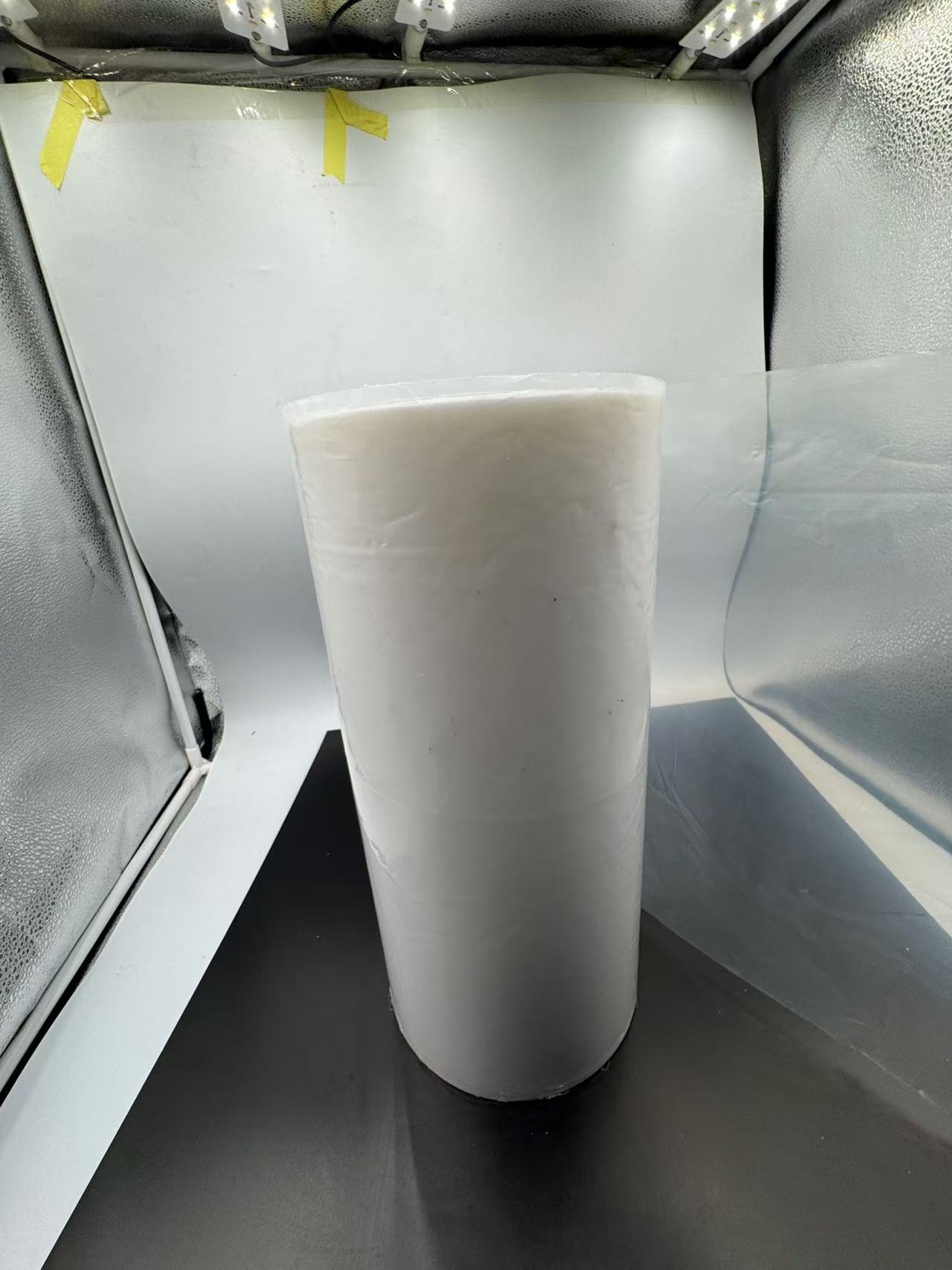

Ⅰ. Introduction to Transparent PE Film

Transparent PE (Polyethylene) film is a ubiquitous material that plays a significant role in various aspects of our daily lives. It is a type of plastic film made from polyethylene resin,

which is known for its versatility and cost-effectiveness. This film is often characterized by its high transparency, allowing clear visibility of the contents it encloses or protects. In our day-to-day encounters, we can find transparent PE film in numerous forms. It is commonly used as a food wrapper, such as the thin, clear film that covers sandwiches, fruits, and baked goods in grocery stores or delis. You might also notice it as the protective covering on electronic devices like smartphones, tablets, and computer monitors during transportation and storage, preventing scratches and damage while still allowing the product's features to be visible. Additionally, it is widely employed in the packaging of various consumer products, from cosmetics and toiletries to stationery and toys, enhancing the visual appeal of the items on the shelves and providing a barrier against dust, moisture, and other contaminants.

Ⅱ. Physical Characteristics of Transparent PE Film

1. Appearance and Transparency

Transparent PE film exhibits a smooth and clear surface, often with a lustrous sheen that gives it an appealing visual quality. Its transparency is remarkable, allowing for a high degree of visibility through the film. When held up to the light, objects on the other side can be seen with great clarity, almost as if there were no barrier present. In comparison to other common films like PVC or PP, transparent PE film offers a more natural and distortion-free view. For instance, when used as a food wrapper, it enables consumers to easily identify the contents inside, enhancing the product's presentation. In the case of packaging delicate items such as jewelry or electronic components, the high transparency of the PE film ensures that the product's details and quality are fully visible, which can be crucial for marketing and quality inspection purposes.

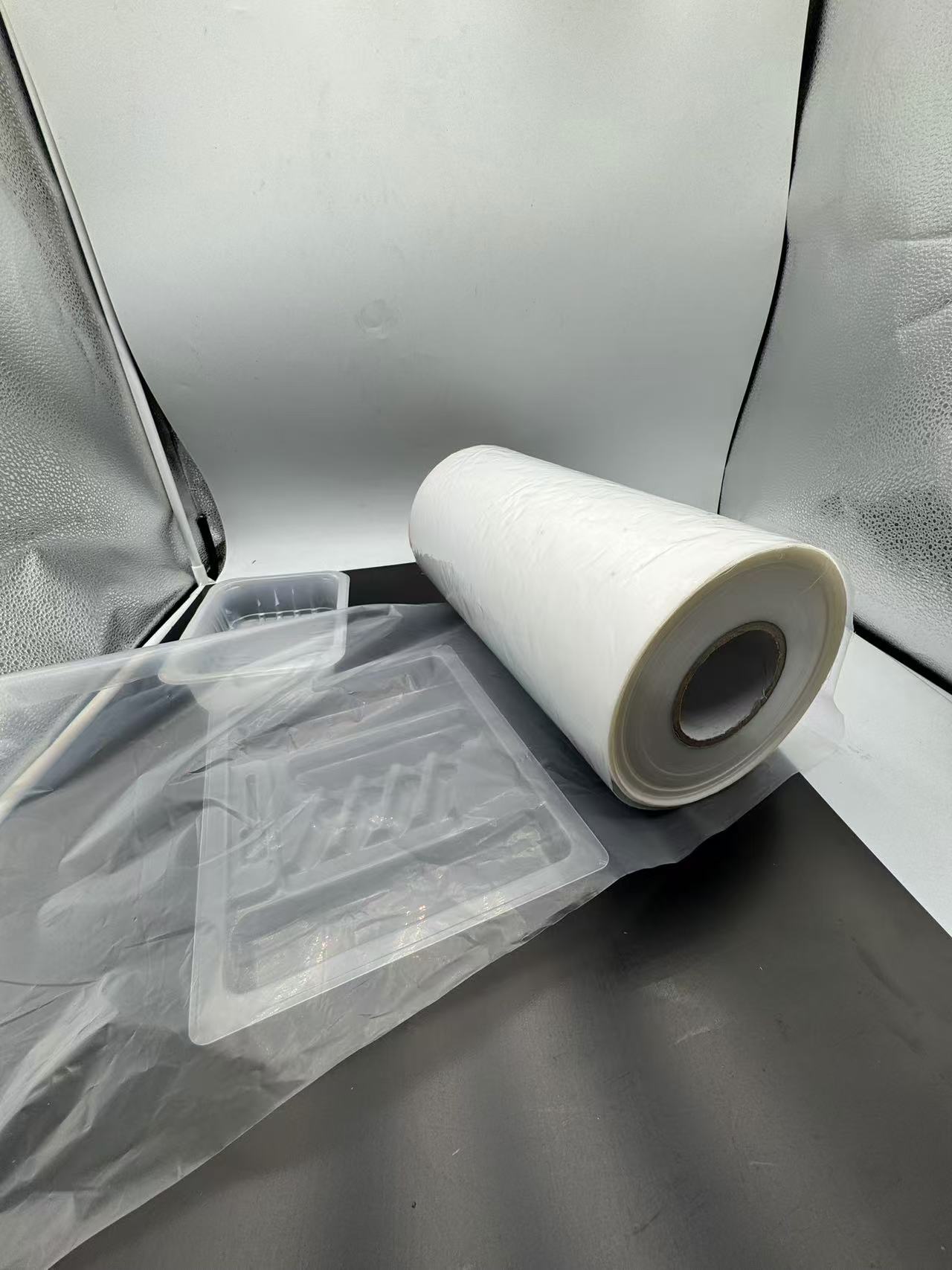

2. Texture and Flexibility

The texture of transparent PE film is typically smooth to the touch, with a certain degree of softness that gives it a pleasant tactile feel. It is not overly rigid or brittle, which contributes to its excellent flexibility. This film can be effortlessly bent, folded, or wrapped around various objects without cracking or breaking. Its flexibility makes it highly adaptable for use in a wide range of applications. For example, in the packaging of irregularly shaped products like toys or sports equipment, the film can conform snugly to the contours of the item, providing a secure and protective covering. In the manufacturing of flexible packaging for liquids, such as pouches for shampoo or sauce, the flexibility of the PE film allows it to withstand the stresses of handling and transportation while maintaining its integrity and preventing leaks.

3. Density and Thickness Varieties

Transparent PE film is available in different densities, namely low-density (LDPE), medium-density (MDPE), and high-density (HDPE). LDPE is known for its excellent transparency and flexibility, making it suitable for applications where a soft and pliable film is required, such as in food packaging for items like bread or fresh produce. MDPE offers a balance between the properties of LDPE and HDPE,

with moderate strength and flexibility, and is often used in applications where a slightly more durable film is needed, such as in the packaging of heavier consumer goods. HDPE, on the other hand, has a higher density and greater mechanical strength, which makes it ideal for applications that demand robustness and resistance to puncture and tearing, such as in the packaging of industrial products or sharp-edged items. In terms of thickness, transparent PE film can range from very thin films used for lightweight and delicate items, such as in the wrapping of small electronic parts or confectionery, to thicker films used for more heavy-duty applications like the packaging of construction materials or large machinery parts. The choice of thickness depends on the specific requirements of the product being packaged, taking into account factors such as the weight, fragility, and protection needs of the item.

Ⅲ. Chemical Properties of Transparent PE Film

1. Chemical Stability

Transparent PE film exhibits remarkable chemical stability, which is one of its most valuable properties. It demonstrates a high resistance to a wide range of chemicals, including acids, alkalis, and common solvents. For instance, in the case of acids, whether it's a mild acetic acid or a stronger hydrochloric acid in a diluted form, the PE film can maintain its integrity and functionality without significant degradation. When used in the packaging of acidic food products like pickles or citrus fruits, the film prevents any interaction with the acid, ensuring the quality and safety of the contents. Similarly, with alkalis, such as sodium hydroxide solutions of moderate concentration, the film remains unaffected. In industrial settings, where it may come into contact with alkaline cleaning agents during the manufacturing process of certain products, its stability ensures that it doesn't break down or contaminate the items being packaged. In terms of common solvents like ethanol, methanol, and acetone, the PE film shows minimal solubility or reactivity. This property is crucial in the packaging of products that contain small amounts of these solvents, such as some pharmaceutical tinctures or cosmetic lotions. Overall, its chemical stability makes it suitable for a diverse range of applications where exposure to various chemicals is a possibility.

Looking ahead, there are several exciting potential applications in the pipeline. In the field of smart packaging, transparent PE film could be integrated with sensors or indicators that change color or display information based on the freshness or quality of the packaged product. For example, a film used for food packaging could contain a sensor that detects the presence of spoilage gases and alerts consumers when the food is no longer safe to eat.

In the medical field, there is potential for the development of transparent PE films with antimicrobial properties, which could be used to wrap surgical instruments or medical devices, reducing the risk of infection. In the energy sector, transparent PE film could play a role in the development of flexible solar cells or energy storage devices, leveraging its flexibility and transparency to create innovative and efficient energy solutions. These are just a few glimpses into the future of transparent PE film, and as research and development continue, we can expect to see even more remarkable and innovative uses for this versatile material.

Ⅹ. Conclusion

In conclusion, transparent PE film has emerged as a remarkable material with a diverse range of characteristics and applications. Its physical properties, such as high transparency, flexibility, and variable density and thickness, make it suitable for a multitude of uses. Chemically, it is stable, non-toxic, and resistant to various environmental factors, enhancing its utility and safety in different industries.

In packaging, it plays a crucial role in protecting and presenting food, pharmaceuticals, and industrial products. In protective applications, it safeguards electronic devices, furniture, and building materials. The agricultural sector benefits from its ability to protect crops and conserve soil and water. Additionally, it has found unique uses in arts and crafts, education, laboratories, and decoration.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film ,

HIPS Film,

PC Film,

PP Film,

Other plastic packaging products