Single Ram BOP, or single ram blowout preventer, is an important wellhead control device commonly used in oil drilling and well repair operations. The following is a description and introduction of it:

Structural composition

Gate assembly: It is the core component, consisting of gate, gate shaft, sealant core, etc. Gates are usually of two types: semi-closed gate and fully closed gate. Semi-closed gate can seal the annular space between the drill pipe and the wellhead, while fully closed gate can completely close the wellhead in an emergency.

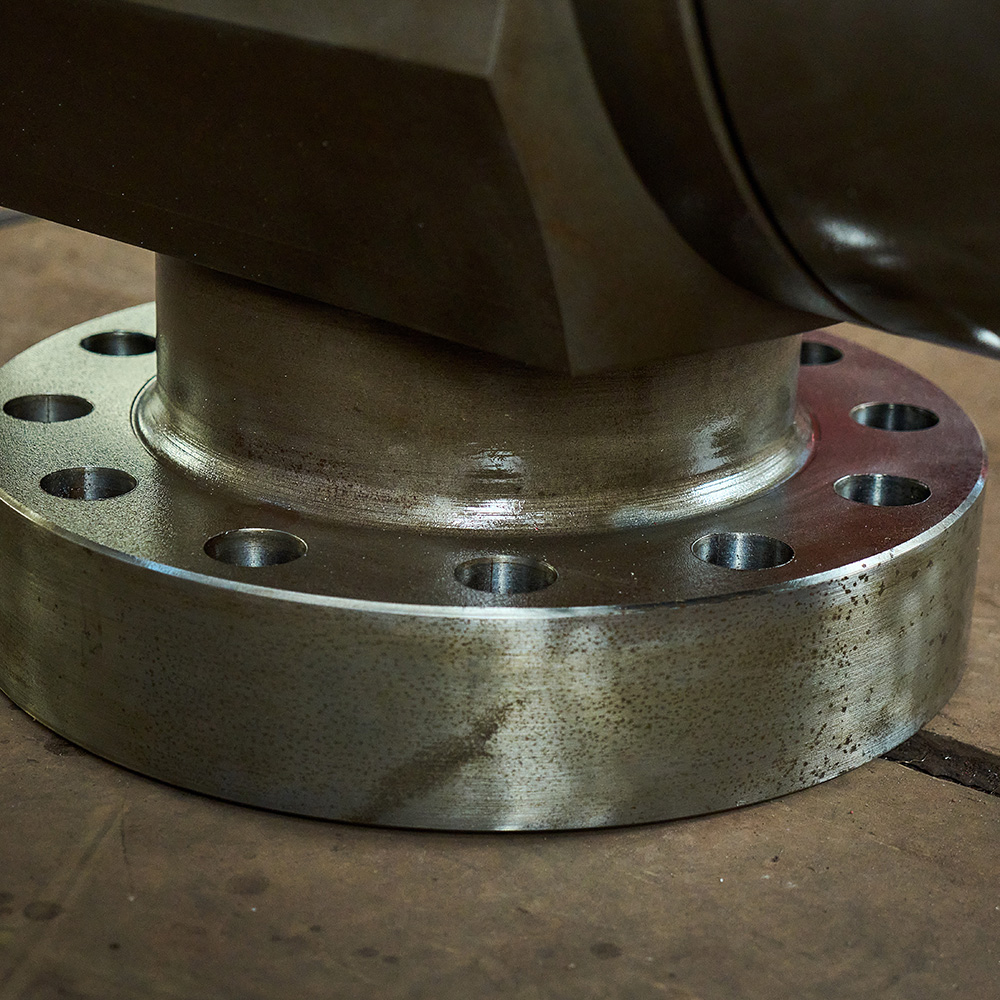

Shell: Generally cast with high-strength alloy steel, with sufficient strength and rigidity to withstand the high pressure in the well. There is space inside the shell to accommodate the gate assembly, and flanges and bolt holes connected to the wellhead are provided.

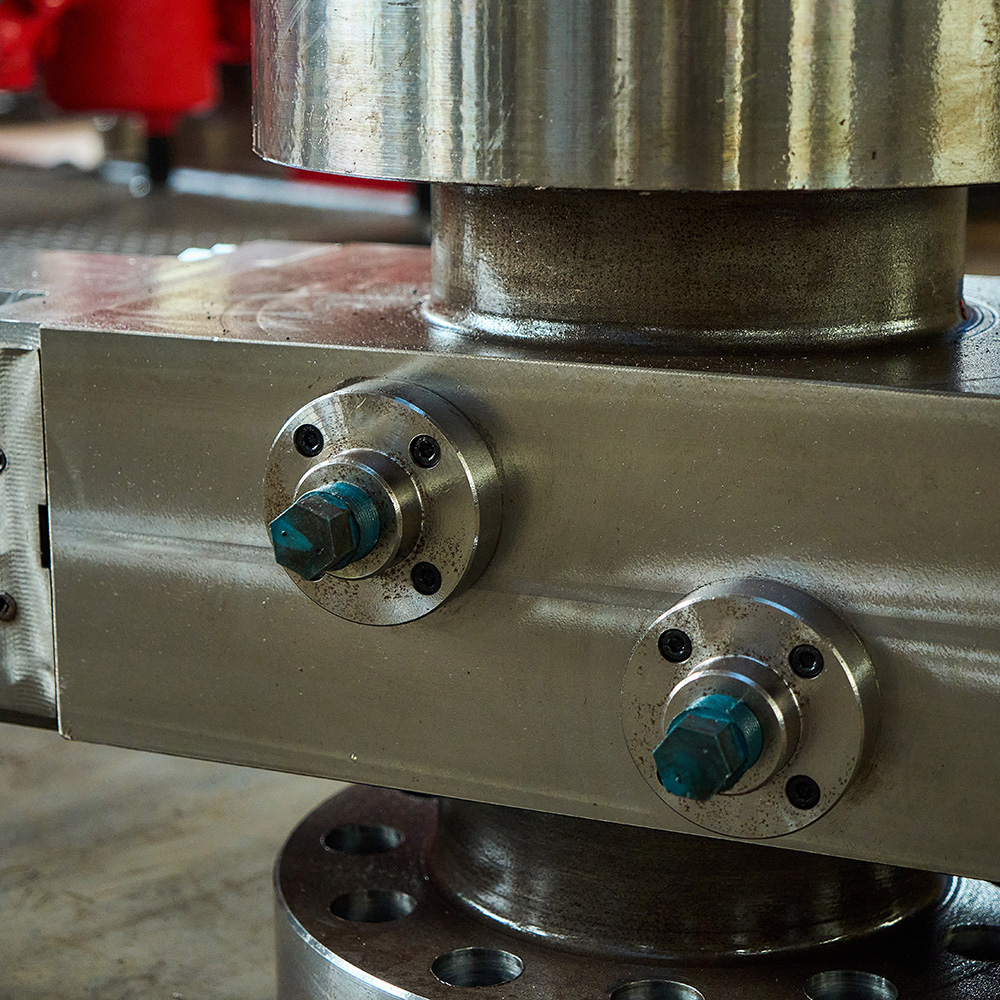

Side door: Located on the side of the shell, it is convenient for installing, disassembling and maintaining the gate assembly and other internal components. The side door is usually tightly connected to the shell by bolts or other connection methods to ensure sealing performance.

Hydraulic control system: It includes hydraulic cylinders, pistons, hydraulic pipelines, etc., which drive the opening and closing of the gate through the pressure of hydraulic oil to achieve control of the wellhead.

| Product Name: |

FZ Single Ram BOP |

| Specification model: |

7 1/16 |

| Implementation standard: |

API 6A |

| Rated working pressure: |

5000psi |

| Product specification level: |

PSL1~PSL3G |

| Product performance level: |

PR1~PR2 |

| Temperature level: |

PU, LU |

| Material level: |

AA~FF |

| Product color: |

silver |

Working Principle

Closing process: When overflow, blowout and other dangerous situations occur at the wellhead, the hydraulic control system injects high-pressure hydraulic oil into the hydraulic cylinder of the blowout preventer to push the piston to move. The piston drives the gate shaft to move the gate toward the center of the wellhead. The sealant core on the gate fits tightly with the drill pipe or wellhead casing under pressure, thereby sealing the wellhead and preventing the fluid in the well from spraying out.

Opening process: When it is necessary to resume drilling or well repair operations, the hydraulic control system discharges the hydraulic oil in the hydraulic cylinder, and the piston moves in the opposite direction under the action of the spring force or other reset device, driving the gate back to the open position. At this time, the drill pipe can move freely up and down in the wellhead or perform other operations.

Function and characteristics

Well control safety guarantee: During drilling and well repair, once the pressure in the well is out of control and dangerous situations such as overflow and blowout occur, Single Ram BOP can quickly close the wellhead, effectively preventing the uncontrolled spraying of high-pressure fluid in the well, avoiding the occurrence of blowout accidents, and protecting the safety of personnel, equipment and the environment.

Easy and flexible operation: It adopts hydraulic control system for operation. It only needs to control the inlet and outlet of hydraulic oil to realize the rapid opening and closing of the gate. The operation is easy and fast. At the same time, the opening and closing position of the gate can be accurately controlled by the travel switch or other position sensors in the hydraulic system to ensure the accuracy and reliability of the operation.

Good sealing performance: The sealant core on the gate is made of high-quality rubber material, which has good elasticity and sealing performance. It can effectively seal the annular space between the drill pipe and the wellhead or completely close the wellhead under different well pressure and temperature conditions. In addition, the sealant core can be replaced according to the size of the drill pipe to adapt to drill pipes of different specifications.

Strong adaptability: It can adapt to different well depths, well pressures and formation conditions. By selecting Single Ram BOP of different specifications and pressure levels, it can meet the needs of various drilling and well repair operations. At the same time, the equipment can also be used in combination with other types of blowout preventers (such as double gate blowout preventers, annular blowout preventers, etc.) to form a more complete wellhead blowout prevention control system.

As a petroleum machinery manufacturer, our company also produces Blowout Preventer, Manifold, Cellar Connection, Valve, Pipe Fitting and Control Apparatus, etc.

If you need, please contact us.

Our Service: