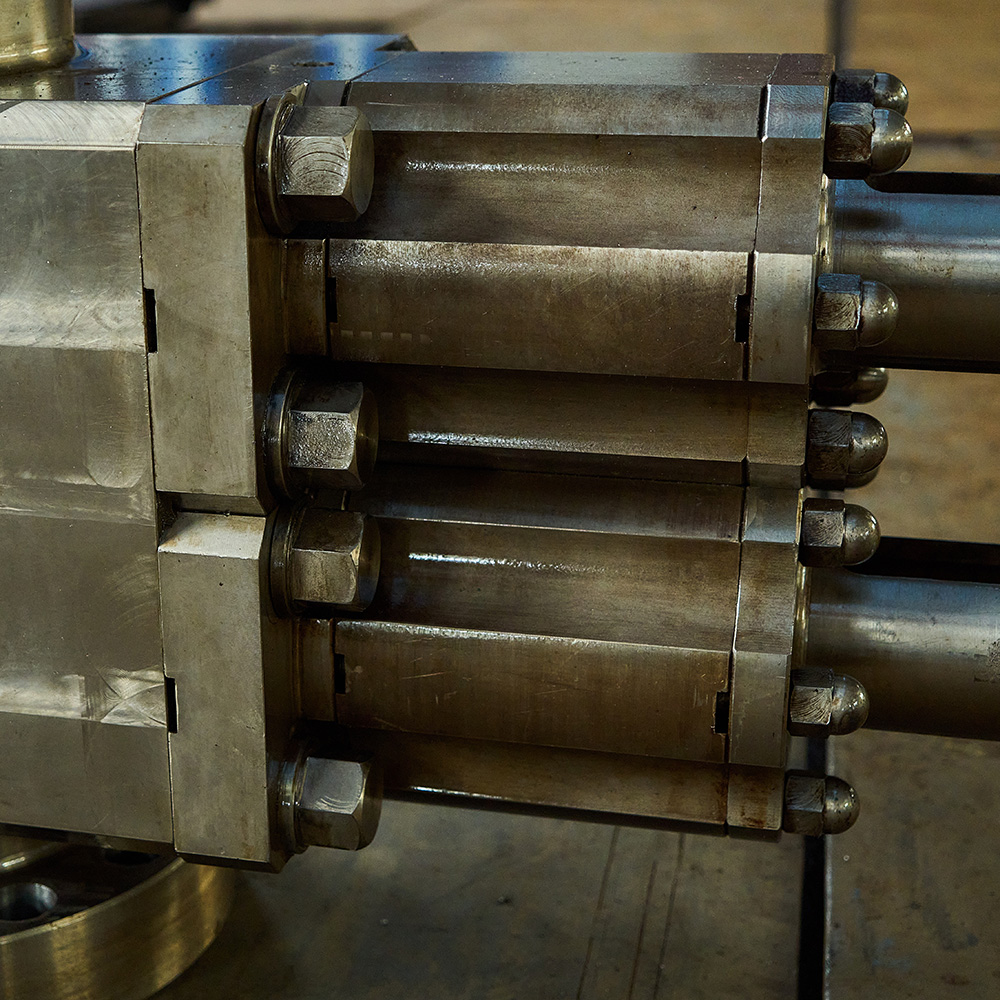

Structural features:

Multi-layer gate design: usually has two layers of gates, semi-sealed and fully sealed, such as 2SFZ18-35 double gate blowout preventer, the upper layer is a semi-sealed gate sealant core assembly, and the lower layer is a fully sealed gate sealant core assembly, which can respectively deal with the two situations of oil pipes in the well and empty wells to achieve well sealing and blowout prevention.

Main components are made of excellent materials: The main components are forged with alloy steel and heat-treated, with high strength. The surface is plated with nickel-phosphorus, which is corrosion-resistant, oil-resistant, acid-resistant and alkali-resistant, and can extend the service life.

Side door and sealing assembly: The side door structure facilitates the installation, maintenance and replacement of the gate. At the same time, the sealing assembly between the components ensures the sealing of the blowout preventer under high-pressure environment, preventing leakage of oil, gas, water and other media.

Working principle

Sealing the well when there is tubing in the well (semi-sealing): During well repair operations, when there is tubing in the well and the downhole pressure changes and there are signs of blowout, the handle is turned to rotate the screw, and the screw moves radially through the inner thread of the gate shaft, driving the gate seal assemblies on both sides to move toward the center, and the gate seal rubber core holds the tubing tightly, thereby sealing the annular space between the tubing and casing in the well to achieve the purpose of blowout prevention.

Sealing the well when the well is empty (full sealing): During well repair operations, if there is no tubing in the well and the downhole pressure changes and there are signs of blowout, the operation is similar to semi-sealing, and the lower symmetrical gate assembly is closed at the same time, so that the gate seal rubber core is relatively compressed to achieve sealing of the empty well to prevent blowout.

Product Parameters:

| Product name |

2FZ double-gate blowout preventer |

| Specification model |

7 1/16 |

| Implementation standard |

API 6A |

| Rated working pressure |

15000psi |

| Product specification level |

PSL1~PSL3G |

| Product performance level |

PR1~PR2 |

| Temperature level |

PU, LU |

| Material level |

AA~FF |

| Product color |

silver |

Technical parameter example

Model: such as 5SFZ18-35, 2SFZ18-35, 2FZ18-35, etc.

Working pressure: Common ones are 35MPa.

Diameter: 180mm is more common.

Dimensions: Varies depending on the specific model, for example, the size of a certain model is 1380480715.

Applicable scenarios

Oil well repair operations: In the daily well repair process of oil wells, whether it is repairing or replacing the oil pipe or other downhole operations, the double-gate blowout preventer can effectively prevent the occurrence of blowout accidents and ensure the safety of operators and equipment.

Oil test operations: During the oil test stage, when the oil layer is tested, the oil, gas and water in the formation may gush out under pressure. The double-gate blowout preventer can close the wellhead in time, control the wellhead pressure, and ensure the smooth progress of the oil test process.

Product advantages

Good sealing performance: With a reliable sealing structure and high-quality sealing rubber core, it can effectively seal the wellhead under high-pressure environment to prevent oil and gas leakage.

Strong reliability: After strict quality testing and actual working condition verification, the product performance is stable and can operate reliably for a long time in a complex downhole environment.

Easy to operate and install: reasonable design, simple operation, easy to install and disassemble, which can reduce the difficulty and workload of on-site operations.

As a petroleum machinery manufacturer, our company also produces Blowout Preventer, Manifold, Cellar Connection, Valve, Pipe Fitting and Control Apparatus, etc.

If you need, please contact us.

Detail Pictures: