As a key component of the flat valve, the flat valve plate plays a core role in the fluid control process in many industrial fields.

Structural design and specifications

Diversified size specifications: The flat valve plate has a variety of size specifications, including 2 9/16 inches, 3 1/8 inches, 4 1/16 inches, etc., to meet the precise adaptation requirements of pipeline systems with different pipe diameters, ensuring that it can be seamlessly connected with the corresponding valve body and pipeline in a wide range of application scenarios in various industries such as oil, natural gas, chemicals, and electricity, thereby ensuring the efficiency and stability of fluid transportation.

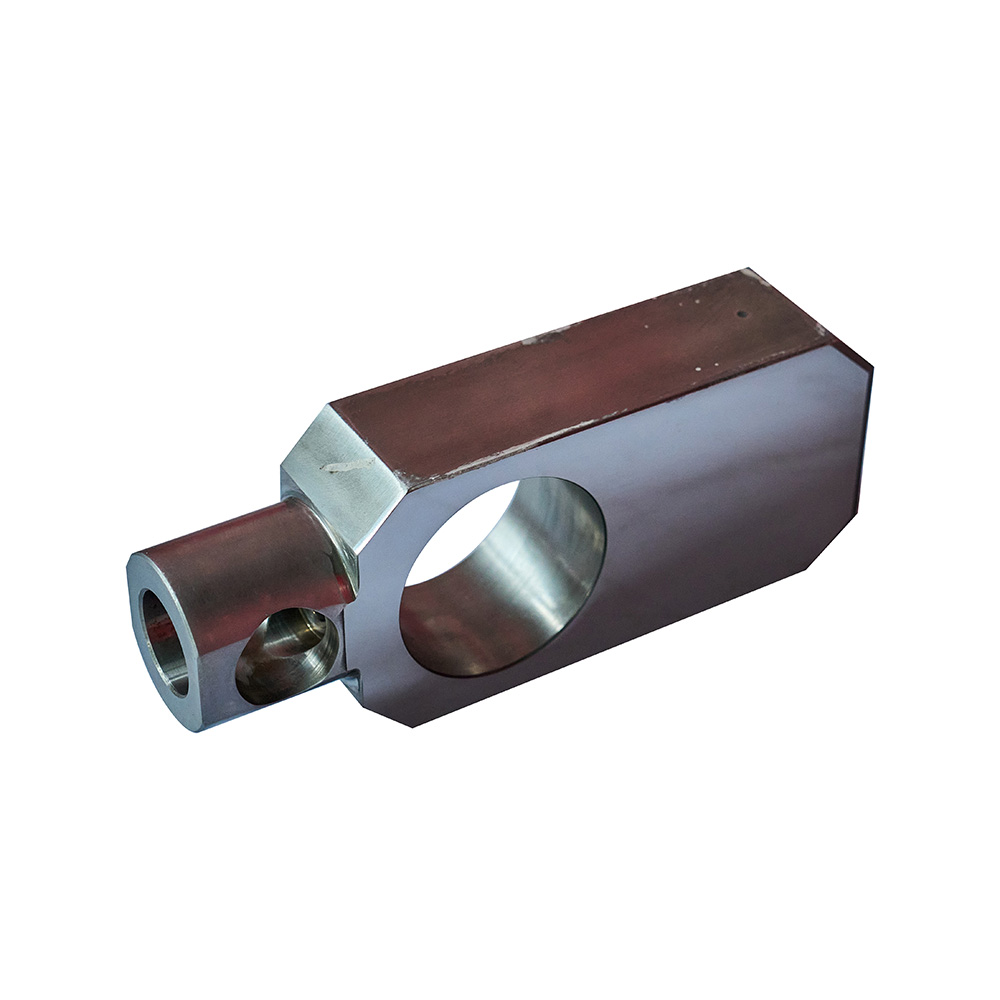

Flat plate structural features: It adopts a simple and efficient flat plate design. The main part is a flat plate structure. The surface has been finely machined and has excellent flatness and finish. This not only helps to reduce the resistance of the fluid when passing through, reduce energy loss, and improve the flow capacity of the valve, but also can form a tight, uniform and reliable sealing contact with the valve seat, effectively preventing fluid leakage and ensuring that the sealing performance of the valve in the closed state is optimal.

Optimized edge treatment: The edge of the valve plate is usually processed with a special rounding or chamfering process. This design detail can further optimize the flow characteristics of the fluid, reduce the turbulence of the fluid at the edge of the valve plate, and reduce the scouring and wear of the valve plate and valve seat by the fluid, thereby extending the service life of the valve plate and the entire valve, and also helping to improve the stability and reliability of the valve during operation.

Product Parameters:

| Product Name: |

Valve plate |

| Specification model: |

3 1/8 |

| Implementation standard: |

API 6A |

| Rated working pressure: |

5000psi |

| Product specification level: |

PSL1~PSL3G |

| Product performance level: |

PR1~PR2 |

| Temperature level: |

PU, LU |

| Material level: |

AA~FF |

| Product color: |

Silver |

Detail Pictures:

Material selection and characteristicsHigh-strength alloy steel material: For applications that withstand high pressure, high temperature and high stress conditions, valve plates are usually made of high-strength alloy steel materials, such as 4130, 4140 and other alloy steel series. After a specific heat treatment process, these alloy steels can obtain excellent strength, toughness and fatigue resistance, so that they can still maintain stable structural integrity under extremely harsh working conditions, effectively resist the impact of fluid pressure and the stress generated by frequent opening and closing operations, ensure the safe and reliable operation of the valve, greatly reduce the risk of downtime maintenance due to valve plate damage, and provide a solid guarantee for the continuity of industrial production.Corrosion-resistant stainless steel material: In environments with corrosive media such as chemical industry, offshore platform, and seawater desalination, stainless steel valve plates are the first choice, and common ones are 304 and 316 stainless steel. Stainless steel has inherent excellent corrosion resistance. The alloy elements such as chromium and nickel it contains can form a dense passivation film on the surface of the valve plate, effectively resisting the erosion of various corrosive substances such as acids, alkalis, and salts, ensuring that the valve plate will not rust, corrode and perforate when in long-term contact with corrosive media, thereby ensuring that the sealing performance and service life of the valve are not affected, reducing equipment maintenance costs and replacement frequency, and improving production efficiency and economic benefits.Application of special alloys and coatings: For some special working conditions, such as high temperature and high pressure oil and gas extraction environments containing corrosive gases such as hydrogen sulfide, the valve plate may use special alloy materials such as nickel-based alloys, or apply coatings with special properties on the surface of ordinary metal valve plates, such as ceramic coatings and tungsten carbide coatings. These special alloys and coatings can provide better resistance to high temperature, wear, corrosion and hydrogen sulfide stress corrosion cracking, further expanding the application range of flat valve discs, making them adaptable to more complex and demanding industrial production environments.As a petroleum machinery manufacturer, our company also produces Blowout Preventer, Manifold, Cellar Connection, Valve, Pipe Fitting and Control Apparatus, etc.If you need, please contact us.