Silica matting agent is a wide using chemical powder in various industrial area including UV paint. Silicon dioxide is a high properties powder

which can enhance the UV paint's properties like hardeness, scratches resistance and durability. Silica matting agent is a white, non-toxic,non-smell

powder and it can not be dispersed into mostly solvents and water.

UV paint is a kind of paint which is using UV light to curing or drying the coatings. This type of paint is wide-using in automotive industry,

aerospace and marine industries due to its excellent using durability. chemical durability and fast-dry property. In UV paint, adding silicon dioxide

can improve paints' properties. High purity silica matting agent is a cherish additive for UV paints which can help to enhance its properties and this silica

matting agent might be used more and more in the near future. Below are the advantages that adding silica matting agent into UV paints.

1. Enhance paints' scratches resistance: nano size silica matting agent can help to improve UV paint's hardeness and scratches resistance. Cause

it enhance the adhesion ability between paints and based objects which can make sure the paint will not crack from the based objects.

2. Enhance light's stability and weather resistance: silica matting agent can adsorb or scatter UV light which can Reduces the direct effects of UV rays

on the paint surface, thereby protecting the paint layer from aging and fading.

3. Provide antifouling properties: The surface of silica is hydrophilic, which can effectively prevent the adhesion of pollutants such as oil and water stains,

keeping the paint surface clean.

4. Improve chemical resistance: Silica can enhance the resistance of UV paint to various chemicals (such as acids, alkalis, solvents, etc.) and improve the

durability of the paint layer.

When using, it should be noted that the amount of silica added should be adjusted according to the formula and performance requirements of the specific

product to achieve the best enhancement effect. At the same time, the dispersibility of nano-scale silica is also one of the key factors. Good dispersibility can

ensure that it is evenly distributed in the paint and give full play to its performance advantages.

Chemical Data

|

Item |

SS-830 |

Loss on drying(105℃,2Hrs) |

≤5.0 |

|

Content of sio2(dry basis) %, |

≥99.0 |

Ignition loss(1000℃,2Hrs) |

≤18.0 |

|

Porosity ml/g |

≥1.20

|

Whiteness |

≥93.0 |

|

Oil absorption, g/100g , g/100g |

140-200 |

PH(5% Liquor) |

6-8 |

|

Particle Size, um(Malvent,D50) |

7.5-8.5 |

Surface Treatment |

Organic |

Characters

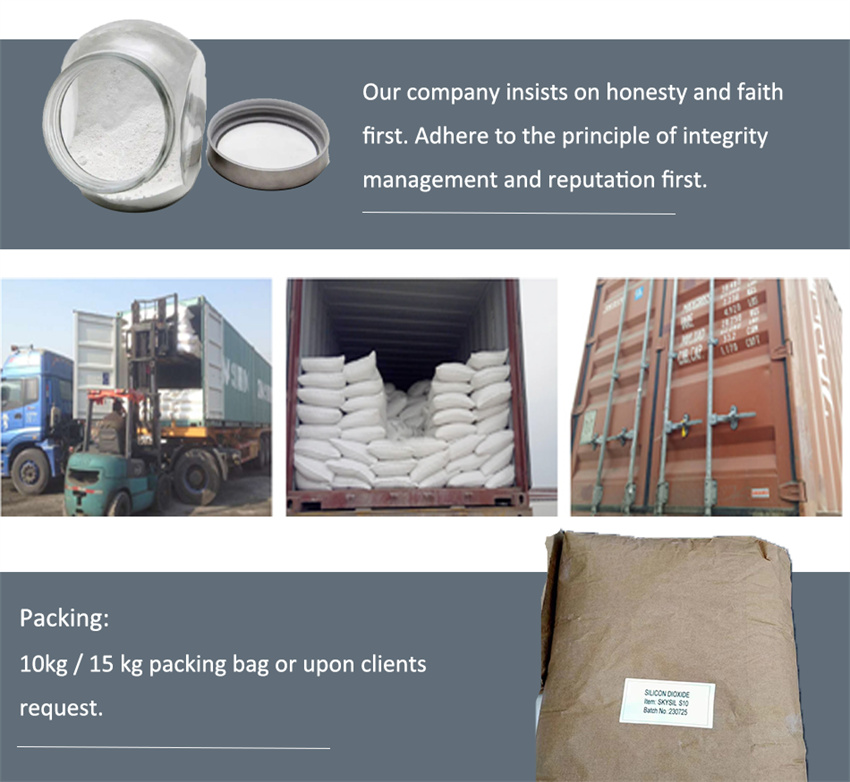

1. white color, texture is relatively light, fluffy.

2. No effect on the drying characteristics of the coating, no effect on the recoating of the coating. Smooth coating

and wear resistance

3. Excellent thixotropy, thickening and anti-sinking

Application

Including UV curtain coating, roller coating, spraying coating.

UV wood coating, UV floor coating, UV plastic coating, UV ink.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Paint Matting Agent ,

Silica Matting Agent ,

Inkjet Receptive Coating,

Nano Alumina,

Teflon Heater,

Anticorrosion Pigments