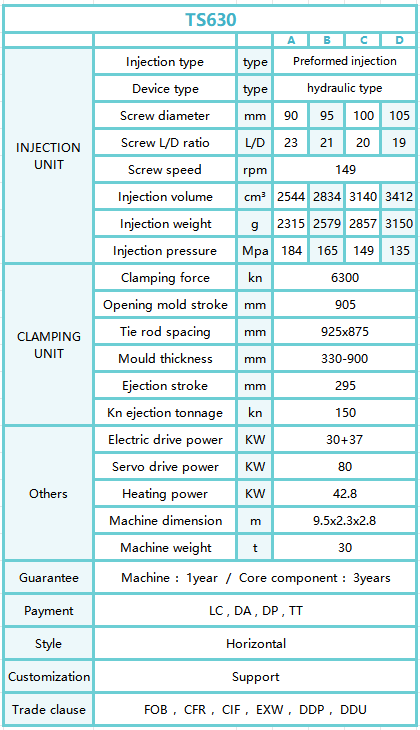

Multifunctional Injection Molding Machine for large Plastic Products

1.Overview

Introducing our cutting-edge plastic injection molding press, specifically engineered for the products of medium-sized plastic products.With its multifaceted capabilities, it stands as a testament to injection molding processing. From small plastic PVC pipes to large plastic trash can, our series of large injection molding machines can be manufactured. This plastic injection molding machine offers an unparalleled blend of performance, versatility, and affordability. Depending on the size and thickness of the plastic product, as well as the production efficiency, please select the model you require.

2.Key Features & Advantages

2.1 Multifunctionality: Our injection molding machine's broad production spectrum makes it an indispensable asset for manufacturers. As one of pvc pipe manufacturing machine supplier,this machine ensures precision and consistency across all large plastic products,providing the best injection molding services.

2.2 High Automation: Equipped with advanced automation features, our custom plastic pvc pipe making machine minimizes human intervention and streamlines production processes. This not only enhances efficiency but also reduces errors and production downtime.

2.3 Cost-Effective Pricing: Despite its sophisticated design and capabilities, we provide competitive injection molding price , offering exceptional value for money. It represents a strategic investment in your manufacturing operations, ensuring long-term savings and profitability.

2.4 Enhanced Safety: Safety is paramount in our design philosophy. This machine injection moulding features multiple safety mechanisms, including emergency stop buttons and protective guards, ensuring a safe work environment for operators.

2.5 High Precision: Precision engineering guarantees impeccable product quality. Every item produced meets industry standards, reflecting the machine's capability to handle intricate details tooling plastic and maintain consistency across batches.

2.6 Energy Efficiency: With energy-saving technology at its core, our machine minimizes electrical consumption. This contributes to reduced operational costs and a smaller carbon footprint, aligning with sustainable manufacturing practices.

2.7 Sustainable Production: Our commitment to sustainability extends to the machine's design. It supports the use of recyclable materials, reducing waste and promoting environmental responsibility.

2.8 High Efficiency & Longevity: Engineered for durability, our machine boasts a long service life and maintains high efficiency over time. This ensures consistent production output and minimizes the need for frequent replacements or repairs.

2.9 User-Friendly Operation: The intuitive control panel and streamlined interface make the machine easy to operate, even for novices. This reduces training time and allows for quick adjustments to production settings.

2.10 High Rigidity & Low Noise: The machine's rigid frame ensures stability during operation, reducing vibrations and enhancing product quality. Additionally, it operates quietly, creating a pleasant working environment.

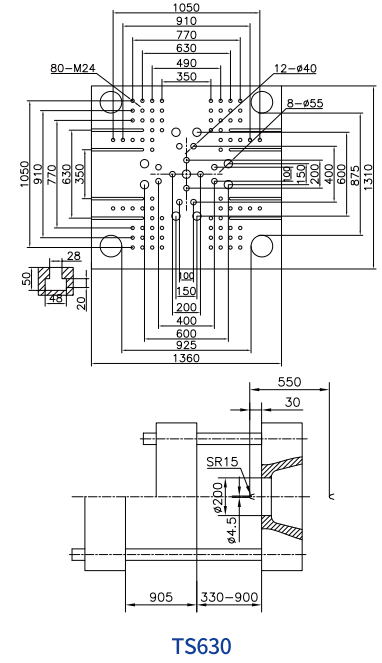

2.11 Wide Tie-Bar Spacing & High Clamping Force: Designed with a large tie-bar spacing, the machine can accommodate molds of various sizes. The high clamping force ensures secure mold closure, preventing leaks and ensuring precise product replication. Suitable for many pvc mold.

3.Market Applications

The versatility of our plastic injection molding equipment makes it suitable for a wide range of industries, including automotive, packaging, construction, and household goods. Its ability to produce high-quality medium-sized plastic products positions you well to tap into these growing markets.

4.Customer Support & Services

We offer comprehensive online customer support, including installation assistance, training sessions, and ongoing maintenance services. Our dedicated team is committed to ensuring your insert molding machine operates seamlessly, maximizing your investment's potential.

We also have specialized machines like cap molding injection machines, nozzle molding making machines, and pipe injection molding machines. Custom injection molders are available for unique requirements. We cover small injection molding for small parts and large scale production alike.We are a leading provider in the field of injection molding, offering a wide range of advanced machines and equipment. Our precision big injection moulding machines are designed to handle large scale and high precision molding tasks. For specific products, we have the cap injection molding machine, which ensures the accurate production of caps. Our pet preform blowing machine and pet test tube molding machine are ideal for manufacturing pet related products. The plastic cup injection moulding machine, alarm clock injection molding machine, basket injection molding machine, and fruit box injection molding machine enable us to produce various household and daily use items with high quality.

The plastic bottle maker, for example, relies heavily on injection molding to produce bottles that are both durable and cost-effective. Similarly, other manufacturers in sectors like automotive, electronics, and medical devices also benefit from this process.When shopping for plastic injection molding equipment or a plastic injection molding machine, it's essential to consider factors such as machine capacity, mold compatibility, and energy efficiency. The injection molding machine price and molding machine price can vary significantly based on these factors and the brand reputation of the manufacturer.Finding the right plastic molding company or injection molding company can also be crucial for ensuring quality and consistency in production. These companies often have extensive experience and expertise in plastic injection molding, allowing them to deliver high-quality products at competitive prices.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Injection molding machine ,

Auxiliary machine,

injection machine Nozzle,

Drive Belt and Pulley,

injection machine Electric Motor,

injection Molds