Membrane filter press is a filter press with an elastic membrane installed between the filter plate and the filter cloth. During use, when the feeding is finished, high-pressure fluid or gaseous medium can be injected into the diaphragm plate. At this time, the entire diaphragm will bulge and press the filter cake to achieve further dehydration of the filter cake, which is usually called squeeze filtration.

Membrane filter press has the advantages of high pressing pressure, good corrosion resistance, convenient maintenance, safety and reliability, etc. It is the first choice for customers in metallurgy, gas, papermaking, coking, pharmacy, food, brewing, fine chemicals and other industries.

Membrane filter presses have been widely used in various fields that require solid-liquid separation. Diaphragm filter press is considered to be an alternative upgrade equipment for ordinary chamber filter press.

Membrane filter presses have shown good results in terms of processing capacity per unit area, reduction of filter cake moisture, and adaptability to the properties of the processed materials.

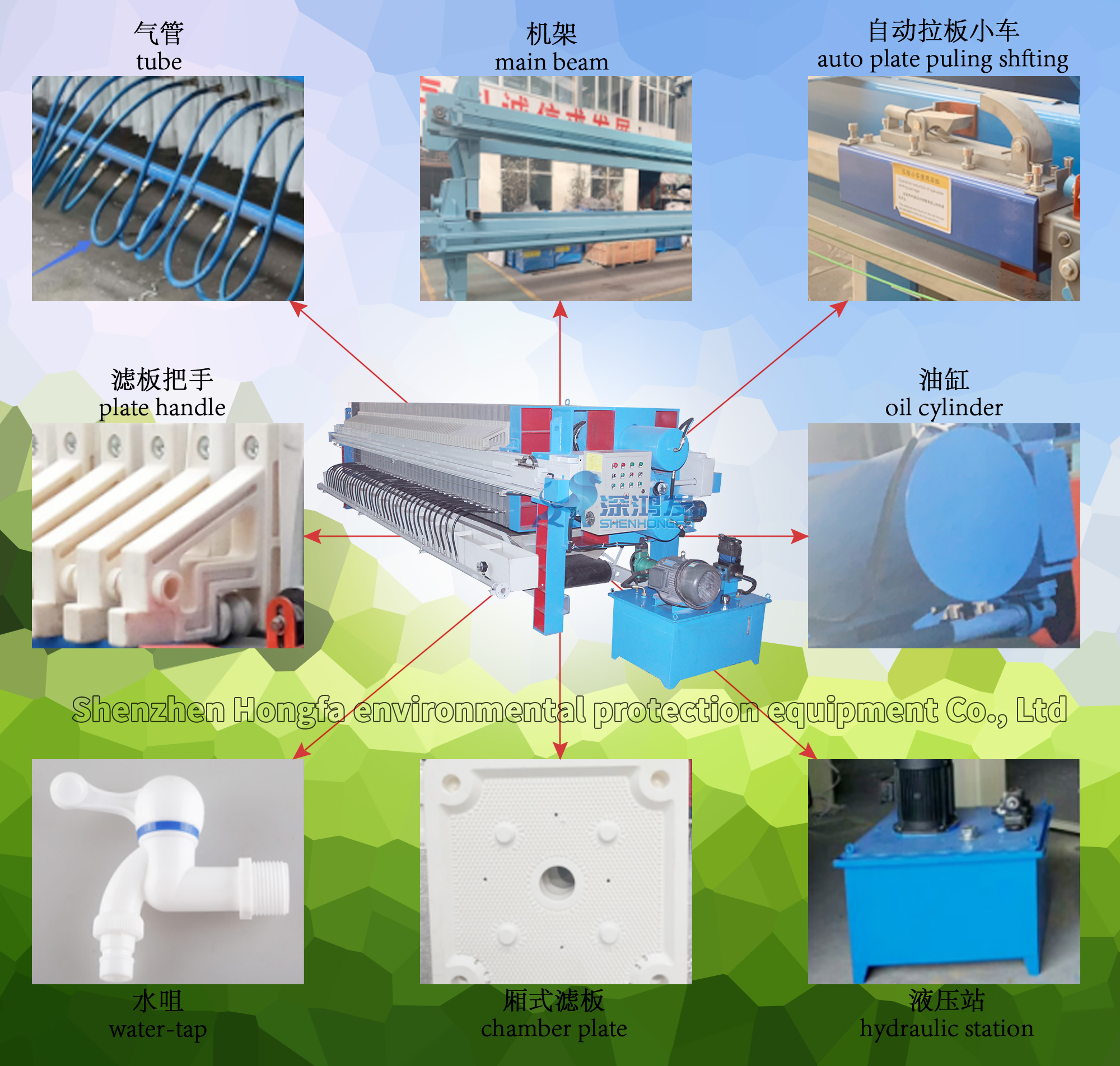

The main difference between the membrane filter press and the ordinary chamber filter press is that two elastic membranes are installed on both sides of the filter plate (the composite rubber diaphragm is an integral diaphragm). During operation, when the feeding is completed, The high-pressure fluid medium can be injected into the diaphragm plate. At this time, the entire diaphragm will bulge and press the filter cake to achieve further dehydration of the filter cake, which is squeeze filtration.

Diaphragm filter press is used in sludge and sewage treatment. The lowest water content of the filter cake has been below 60%. Compared with the traditional chamber filter press, the highest solid content of the filter cake can be increased by more than 2 times. The cost of filter cake transportation Greatly reduced, the filter cake can be directly burned in the power plant, truly turning sludge into resources and sewage into clear springs, completely replacing the van filter press.

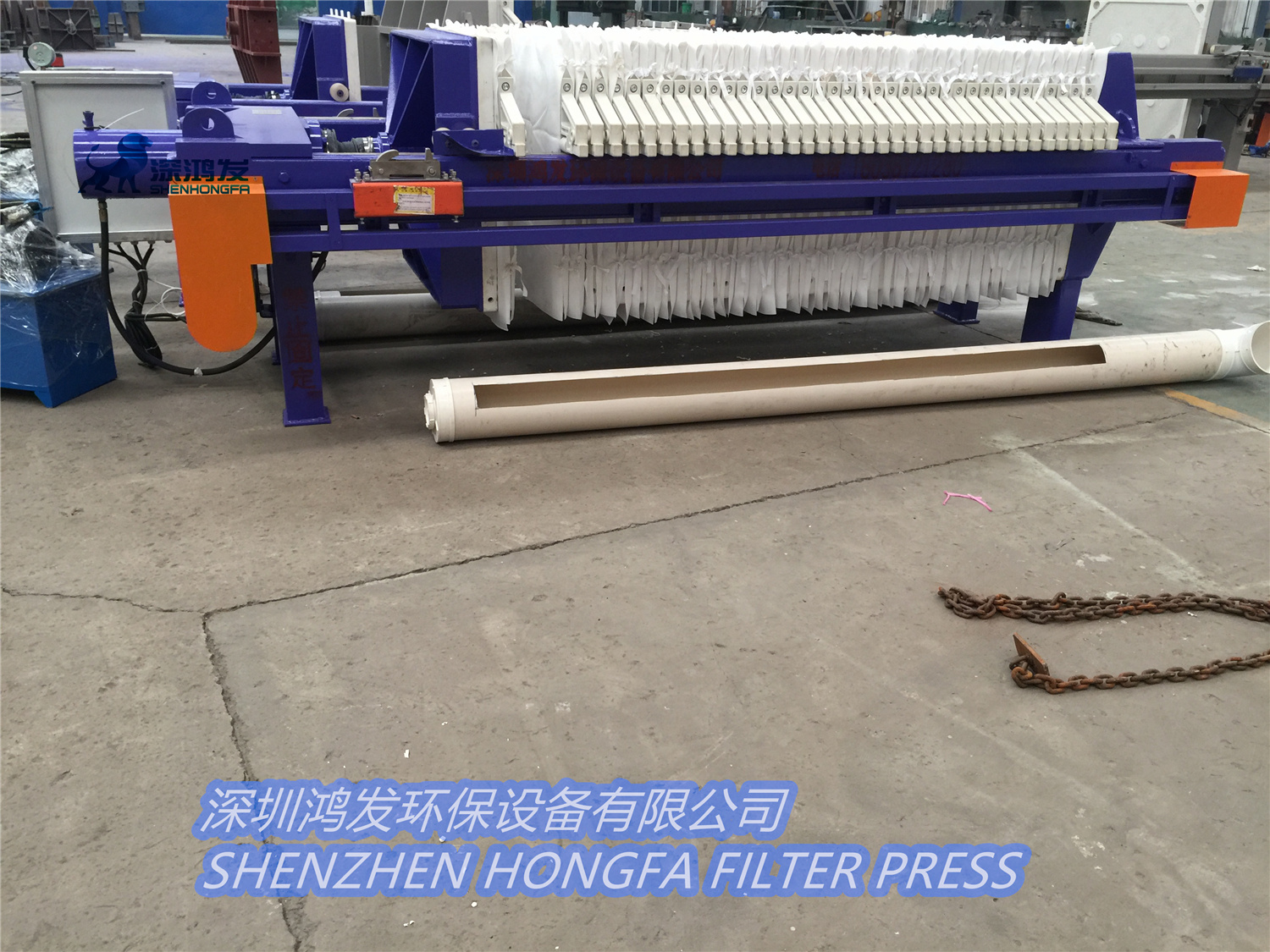

Due to its excellent filtration effect, membrane filter presses have proven themselves in many applications, such as in the mining, chemical or pharmaceutical industries. In order to meet the different requirements of industry and municipal administration, JingJin membrane filter press adopts modular design similar to box filter press. The strong and durable steel filter press frame is composed of the following main components to form the foundation: a feed table with a filtrate outlet (head piece), a hydraulic table with a locking cylinder (press block), a beam and a separate membrane for the side rails The filter plate includes filter cloth. The plate pack consists of a uniform membrane plate with a 15-50 mm cutout (the mixing chamber membrane filter plate is also optional) to accommodate the puncture-resistant filter cake. The standard membrane materials used are polypropylene (PP), synthetic rubber (such as NBR, EPDM) or thermoplastic elastomer (TPE). Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake. This makes the membrane filter press the most powerful and widely used system. Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake. This makes the membrane filter press the most powerful and widely used system. Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake. This makes the membrane filter press the most powerful and widely used system.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Filter Press,

Plate and Frame Filter Press ,

Chamber Filter Press,

Membrane Filter Press,

Wastewater Treatment ,

filter press pump