Membrane Filter Press for Pharmaceutical Industry

Filter press according to the filter plate shape is divided into square filter press and round filter press, more common on the market of filter plate is square, circular filter plate of filter press is less, only a few manufacturer in current domestic can produce round high pressure membrane filter press, especially in the field of ultrahigh pressure filter press technology accomplished manufacturers is less and less. High pressure circular filter press is widely used in solid-liquid separation of stone wastewater, ceramics, kaolin, bentonite, active soil, building materials and other industries due to its high filtration pressure and low water content of cake.

Characteristics of circular plate high-pressure membrane filter press:

1, the system uses mechanical and electrical equipment liquid, PLC system control, complete automatic pulling plate, practical operation is simple, reduce personnel cost;

2, the selection of automatic turning plate liquid collection, solve the problem of the slag water separation is not easy, improve the quality of products and reduce the burden of natural environment cleaning;

3, the filter plate is imported polymer PE material, high pressure stamping 1 forming, longer service life;

4, according to the characteristics of raw materials, the proportion of different general than ordinary filter press can increase the solid content of nearly 10%;

5, high standard production process and technical application, all aspects, to ensure the high quality of each equipment, is the ideal solid-liquid separation equipment machine equipment.

Advantages of round plate high-pressure filter press:

1, choose ring filter plate design concept, with stable operation, feeding pressure is very large, low water content of cake.

2, the selection of high strength toughness polypropylene material, high compressive strength.

3. Linear sealing ring is selected for the filter chamber, which has good airtightness and ultra-high pressure resistance.

Specifications of Membrane Filter Press Machine:

| Model |

Filter Area (m2) |

Plate Size (mm) |

Cake Thickness (mm) |

Volume (L) |

Plate QTY (PCS) |

Pressure (MPa) |

Dimensions (mm) |

| XMGZ 30/870 | 30 | 870*870 | ≤30 | 427 | 23 |

Feeding: ≤1 MPa, Squeezing: ≤1.5 MPa |

3880*1250*1300 |

| XMGZ 40/870 | 40 | 534 | 29 | 4270*1250*1300 | |||

| XMGZ 50/870 | 50 | 676 | 37 | 4790*1250*1300 | |||

| XMGZ 60/870 | 60 | 818 | 45 | 5310*1250*1300 | |||

| XMGZ 70/870 | 70 | 960 | 53 | 5830*1250*1300 | |||

| XMGZ 80/870 | 80 | 1103 | 61 | 6350*1250*1300 | |||

| XMGZ 50/1000 | 50 | 1000*1000 | 665 | 27 | 4270*1500*1400 | ||

| XMGZ 60/1000 | 60 | 808 | 33 | 4700*1500*1400 | |||

| XMGZ 70/1000 | 70 | 950 | 39 | 5130*1500*1400 | |||

| XMGZ 80/1000 | 80 | 1093 | 45 | 5560*1500*1400 | |||

| XMGZ 100/1000 | 100 | 1378 | 57 | 6410*1500*1400 | |||

| XMGZ 120/1000 | 120 | 1663 | 69 | 7260*1500*1400 | |||

| XMGZ 80/1250 | 80 | 1250*1250 | ≤35 | 1364 | 29 | 4830*1800*1600 | |

| XMGZ 100/1250 | 100 | 1680 | 37 | 5440*1800*1600 | |||

| XMGZ 120/1250 | 120 | 2092 | 45 | 6060*1800*1600 | |||

| XMGZ 140/1250 | 150 | 2547 | 55 | 6820*1800*1600 | |||

| XMGZ 160/1250 | 160 | 2729 | 59 | 7130*1800*1600 | |||

| XMGZ 180/1250 | 200 | 3457 | 73 | 8200*1800*1600 | |||

| XMGZ 200/1250 | 240 | 4093 | 89 | 9420*1800*1600 | |||

| XMGZ 250/1250 | 250 | 4276 | 91 | 9570*1800*1600 | |||

| XMGZ 200/1500 | 200 | 1500*1500 | 3866 | 49 | 7140*2200*1820 | ||

| XMGZ 250/1500 | 250 | 4399 | 61 | 7730*2200*1820 | |||

| XMGZ 300/1500 | 300 | 5199 | 73 | 8720*2200*1820 | |||

| XMGZ 350/1500 | 350 | 6132 | 85 | 10110*2200*1820 | |||

| XMGZ 400/1500 | 400 | 6932 | 99 | 11260*2200*1820 | |||

| XMGZ 450/1500 | 450 | 7731 | 111 | 12250*2200*1820 | |||

| XMGZ 500/1500 | 500 | 8665 | 123 | 13240*2200*1820 | |||

| XMGZ 500/1999 | 500 | 2000*2000 | ≤40 | 9686 | 69 | 10310*2850*2400 | |

| XMGZ 600/2000 | 600 | 11900 | 85 | 11580*2850*2400 | |||

| XMGZ 700/2000 | 700 | 13838 | 99 | 12740*2850*2400 | |||

| XMGZ 800/2000 | 800 | 15775 | 113 | 14100*2850*2400 | |||

| XMGZ 900/2000 | 900 | 17851 | 128 | 15365*2850*2400 | |||

| XMGZ 1000/2000 | 1000 | 19788 | 142 | 16625*2850*2400 |

PRODUCT SHOW

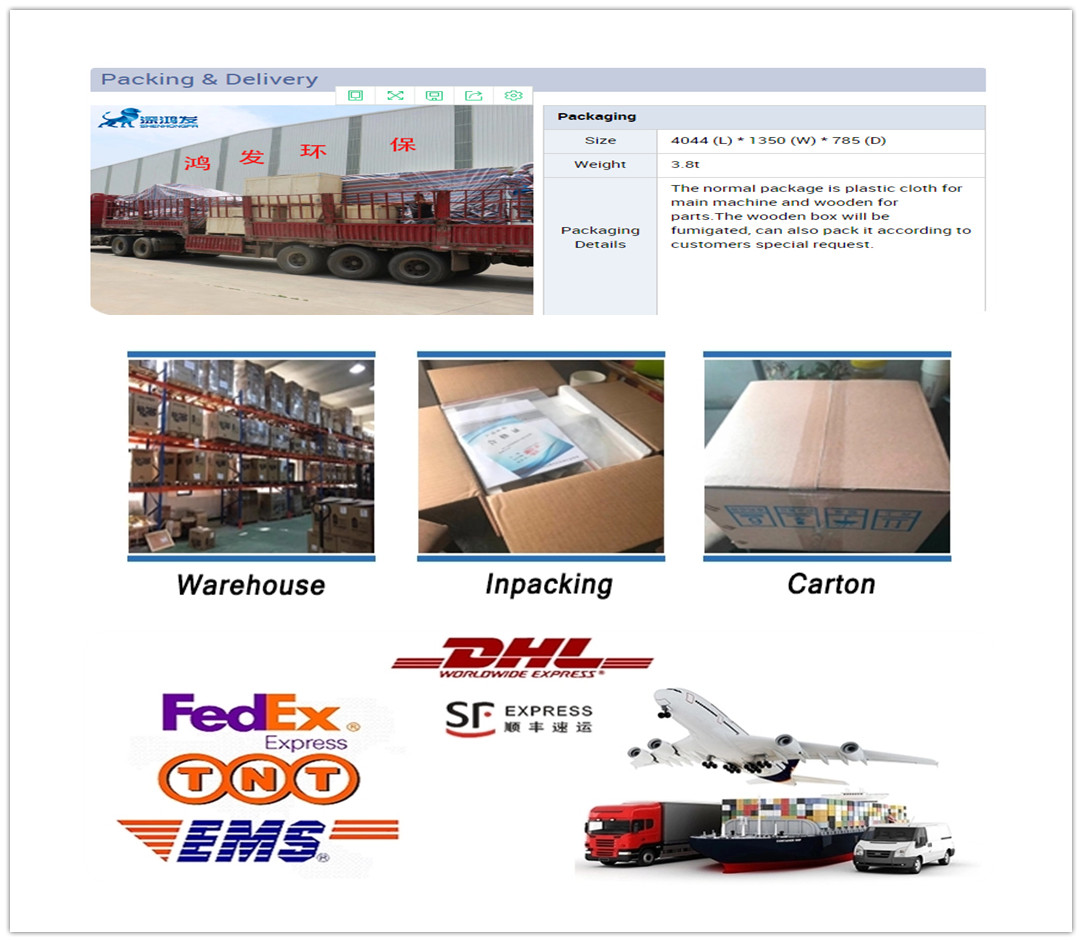

PACKING AND DELIVERY

Our Engineering Project

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Filter Press,

Plate and Frame Filter Press,

Chamber Filter Press,

Membrane Filter Press,

Wastewater Treatment ,

filter press pump